A kind of non-stoichiometric oxynitride nanopowder and preparation method thereof

A non-stoichiometric, oxynitride technology, applied in nanotechnology and other directions, can solve the problems of prolonged preparation time, slow gas-solid reaction diffusion, etc., and achieve the effects of improving purity, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of the non-stoichiometric oxynitride nanopowder of the present invention, comprising the following steps:

[0032] (1) 3g of europium trioxide, 3.75g of tantalum pentoxide and 5.45g of urea were added to 50mL of absolute ethanol, and ball milled for 240min to obtain a mixed slurry;

[0033] (2) Drying the mixed slurry obtained in step (1), the drying process is as follows: heat preservation at 60°C for 24 hours to obtain mixed precursor powder;

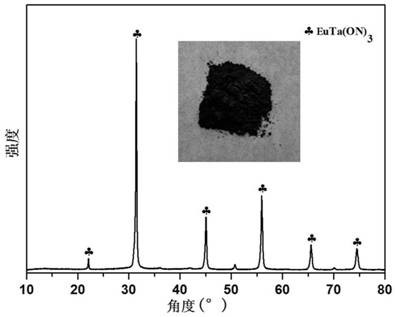

[0034](3) Place the mixed precursor powder obtained in step (2) in a crucible, and then calcined in a nitrogen atmosphere at a heating rate of 100°C / min, a temperature of 1100°C, and a holding time of 1min; finally, it was cooled to room temperature with the furnace, that is Get EuTa(O,N) 3 Oxynitride nano powder;

[0035] (4) EuTa(O,N) obtained in step (3) 3 The oxynitride nano powder is subjected to ammoniation annealing treatment in an ammonia atmosphere, that is, the temperature is raised to 1100°C (...

Embodiment 2

[0038] A preparation method of the non-stoichiometric oxynitride nanopowder of the present invention, comprising the following steps:

[0039] (1) Add 3 g of europium trioxide powder, 3.75 g of tantalum pentoxide powder and 5.45 g of urea into 50 mL of absolute ethanol, and ball mill for 240 min to obtain a mixed slurry;

[0040] (2) Dry the mixed slurry obtained after ball milling in step (1). The drying process is as follows: heat preservation at 60° C. for 24 hours to obtain mixed precursor powder;

[0041] (3) Place the mixed precursor powder obtained in step (2) in a crucible, and then calcined in a nitrogen atmosphere at a heating rate of 100°C / min, a temperature of 1100°C, and a holding time of 1min; finally, it was cooled to room temperature with the furnace, that is Get EuTa(O,N) 3 Oxynitride nano powder;

[0042] (4) EuTa(O,N) obtained in step (3) 3 The oxynitride nanopowder is subjected to ammoniation annealing treatment in an ammonia atmosphere, that is, the tem...

Embodiment 3

[0044] A preparation method of the non-stoichiometric oxynitride nanopowder of the present invention, comprising the following steps:

[0045] (1) Add 3 g of europium trioxide powder, 3.75 g of tantalum pentoxide powder and 5.45 g of urea into 50 mL of absolute ethanol, and ball mill for 240 min to obtain a mixed slurry;

[0046] (2) Dry the mixed slurry obtained after ball milling in step (1). The drying process is as follows: heat preservation at 60° C. for 24 hours to obtain mixed precursor powder;

[0047] (3) Place the mixed precursor powder obtained in step (2) in a crucible, and then calcined in a nitrogen atmosphere at a heating rate of 100°C / min, a temperature of 1100°C, and a holding time of 1min; finally, it was cooled to room temperature with the furnace, that is Get EuTa(O,N) 3 Oxynitride nano powder;

[0048] (4) EuTa(O,N) obtained in step (3) 3 The oxynitride nano powder is subjected to ammoniation annealing treatment in an ammonia atmosphere, that is, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com