Low-cost environment-friendly tundish fire clay, preparation method and construction method

A tundish, low-cost technology, applied in the field of refractory materials, can solve the problems of human body and environmental damage and pollution, inconvenient application, low cost performance, etc., and achieve the effect of significant economic benefits, easy on-site construction, and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

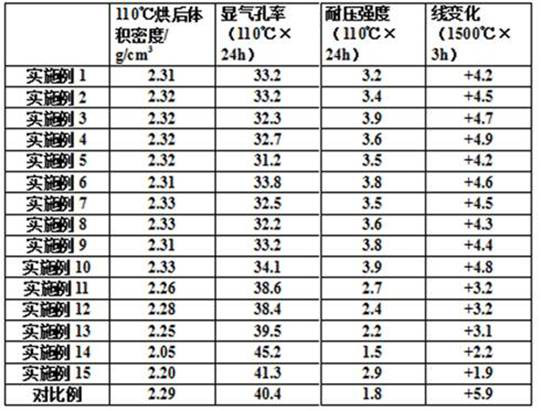

Examples

Embodiment 1

[0034] A low-cost environment-friendly tundish fire clay described in this embodiment, calculated according to the mass parts, its preparation raw materials include the following components:

[0035] 34 parts of recycled alumina-magnesia brick waste with a particle size of 0.074-0.083mm, 60.6 parts of magnesite with a particle size of 0.074-0.083mm, 2.1 parts of silicon micropowder with a particle size of 3-10μm, and 1.8 parts of clay with a particle size of 0.044-0.074mm, 1.2 parts of aluminate cement with a particle size of 0.04-0.09 mm, 0.2 parts of water reducer KF21, and 0.1 part of polypropylene fiber.

[0036] Among them, in recycled alumina-magnesia brick waste, Al 2 o 3 Content ≥ 50wt%, C content ≥ 4wt%;

[0037] In magnesite, MgO content ≥ 40wt%;

[0038] Silica powder, SiO 2 Content ≥ 92wt%;

[0039] In clay, Al 2 o 3 Content≥30wt%, SiO 2 Content≤55wt%, Fe 2 o 3 Content≤2.0wt%;

[0040] In aluminate cement, Al 2 o 3 The content is 66wt%-74wt%, and the C...

Embodiment 2

[0046] A low-cost environment-friendly tundish fire clay described in this embodiment, calculated according to the mass parts, its preparation raw materials include the following components:

[0047] 31 parts of recycled alumina-magnesia brick waste with a particle size of 0.074-0.083mm, 63.4 parts of magnesite with a particle size of 0.074-0.083mm, 2.9 parts of silicon micropowder with a particle size of 3-10μm, and 0.9 parts of clay with a particle size of 0.044-0.074mm, 1.38 parts of aluminate cement with a particle size of 0.04-0.09 mm, 0.3 parts of water reducer KF21, and 0.12 parts of polypropylene fiber.

[0048] Among them, in recycled alumina-magnesia brick waste, Al 2 o 3 Content ≥ 50%, C content ≥ 4%;

[0049] In magnesite, MgO content ≥ 40%;

[0050] Silica powder, SiO 2 Content ≥ 92%;

[0051] In clay, Al 2 o 3 Content ≥ 30%, SiO 2 Content≤55%, Fe 2 o 3 Content≤2.0%;

[0052] In aluminate cement, Al 2 o 3 The content is 66-74wt%, and the CaO content i...

Embodiment 3

[0058] A low-cost environment-friendly tundish fire clay described in this embodiment, calculated according to the mass parts, its preparation raw materials include the following components:

[0059] 28 parts of recycled alumina-magnesia brick waste with a particle size of 0.074-0.083mm, 66 parts of magnesite with a particle size of 0.074-0.083mm, 2.4 parts of silicon micropowder with a particle size of 3-10μm, and 1.5 parts of clay with a particle size of 0.044-0.074mm, 1.39 parts of aluminate cement with a particle size of 0.04-0.09 mm, 0.6 parts of water reducer KF21, and 0.11 parts of polypropylene fiber.

[0060] Among them, in recycled alumina-magnesia brick waste, Al 2 o 3 Content ≥ 50%, C content ≥ 4%;

[0061] In magnesite, MgO content ≥ 40%;

[0062] Silica powder, SiO 2 Content ≥ 92%;

[0063] In clay, Al 2 o 3 Content ≥ 30%, SiO 2 Content≤55%, Fe 2 o 3 Content≤2.0%;

[0064] In aluminate cement, Al 2 o 3 The content is 66-74wt%, and the CaO content is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com