High-performance plastic packaging bag

A high-performance plastic and packaging bag technology, applied in the field of plastic processing, can solve the problems of plastic packaging bags with insignificant anti-mold and antibacterial properties, insignificant mechanical properties of plastic packaging bags, and shorten the life of packaged products, so as to weaken the interface effect, The effect of enhancing mechanical properties and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

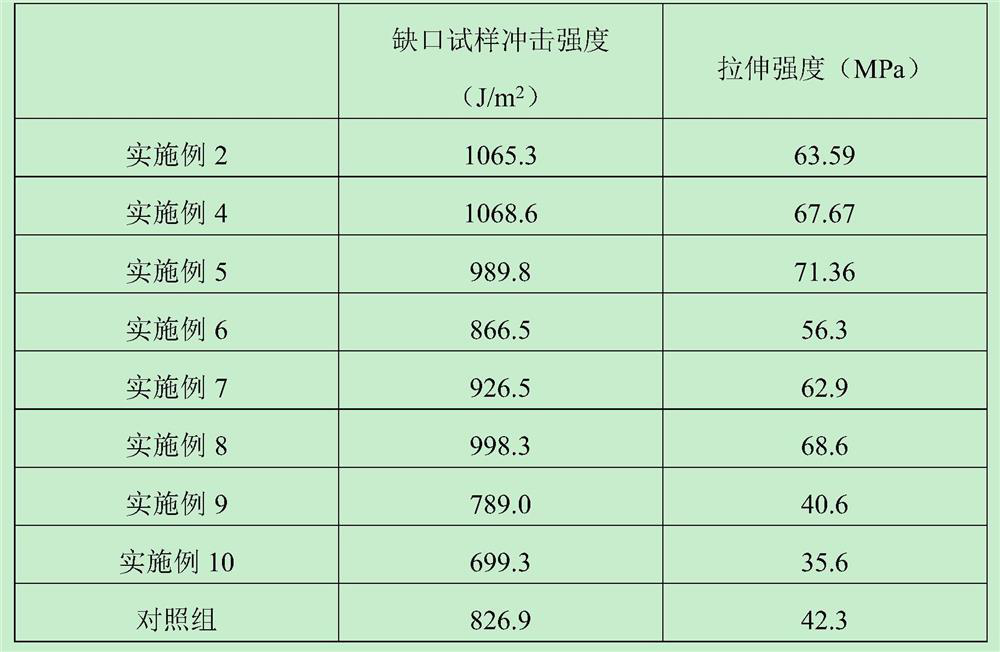

Examples

preparation example Construction

[0028] (1) Preparation of functional filler A:

[0029] a. The sepiolite is placed in a bead mill for grinding, and the sepiolite powder is obtained after completion;

[0030] b. Immerse the ground sepiolite powder in operation a into the treatment solution, and then place it on a shaking table for shaking and soaking treatment. During the shaking and soaking treatment, control the speed of the shaking table to 100-120rpm, and the temperature in the treatment solution to be 35-39 ℃, 3~4h after suction filtration, and then put it in a vacuum drying oven for low temperature vacuum drying treatment. During low temperature vacuum drying treatment, the temperature is controlled at 35~41℃, the vacuum degree is 1.3~1.7Pa, and dried until the moisture content is 2 to 4%, the components in the treatment solution and their corresponding weight percentages are: germanne 2 to 3%, α-bisabolol 3 to 4%, tartaric acid 1 to 2%, fulvic acid 2 to 3%, β - 0.6-0.9% of pinene, 2-3% of artemisinin,...

Embodiment 1

[0040] A kind of high-performance plastic packaging bag, its preparation comprises the steps:

[0041] (1) Preparation of functional filler A:

[0042] a. The sepiolite is placed in a bead mill for grinding, and the sepiolite powder is obtained after completion;

[0043] b. Immerse the ground sepiolite powder in operation a into the treatment solution, and then place it on a shaking table for shaking and soaking treatment. During the shaking and soaking treatment, control the speed of the shaking table to 100rpm, and the temperature in the treatment solution to be 35°C. After 3 hours, Suction filtration, and then placed in a vacuum drying box for low-temperature vacuum drying treatment. During low-temperature vacuum drying treatment, the temperature is controlled at 35 ° C, the vacuum degree is 1.3 Pa, and the moisture content is 2%. The percentage by weight is: germanne 2%, α-bisabolol 3%, tartaric acid 1%, fulvic acid 2%, β-pinene 0.6%, artemisinin 2%, and the balance is ab...

Embodiment 2

[0052] A kind of high-performance plastic packaging bag, its preparation comprises the steps:

[0053] (1) Preparation of functional filler A:

[0054]a. The sepiolite is placed in a bead mill for grinding, and the sepiolite powder is obtained after completion;

[0055] b. Immerse the ground sepiolite powder in operation a into the treatment solution, and then place it on a shaking table for shaking and soaking treatment. During the shaking and soaking treatment, control the speed of the shaking table to 110rpm, and the temperature in the treatment solution is 37°C for 3.5h After suction filtration, it can be placed in a vacuum drying box for low-temperature vacuum drying treatment. During low-temperature vacuum drying treatment, the temperature is controlled at 38°C, the vacuum degree is 1.5Pa, and the moisture content is 3%. Corresponding percentages by weight are: germanne 2.5%, α-bisabolol 3.5%, tartaric acid 1.5%, fulvic acid 2.5%, β-pinene 0.75%, artemisinin 2.5%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com