Slag-corrosion-resistant coating for steel ladle carbon-free tank lining and preparation method of slag-corrosion-resistant coating

A technology of slag erosion and carbon tank, which is applied in the field of slag erosion-resistant coatings for steel ladle carbon-free tank lining and its preparation, and can solve the problems of slag erosion damage, tank lining damage, and the residual thickness of tank lining not meeting the requirements for safe use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

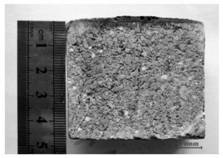

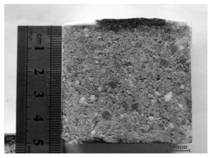

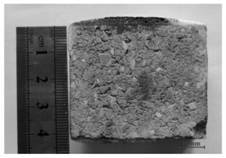

Image

Examples

Embodiment 1

[0051] A kind of anti-slag erosion coating for steel ladle carbonless tank lining, by weight:

[0052] 65 parts of fused magnesium aluminum spinel, 5 parts of zirconium dioxide, 1 part of boric anhydride (boron trioxide), pH=3 (SiO 2 : 30%) of 20 parts of highly stable nano-silica sol, 5 parts of citric acid solution with pH=2, 2 parts of KH-570 coupling agent, and 2 parts of polycarboxylate water reducer FD35.

[0053] A kind of preparation method of anti-slag erosion coating for ladle carbonless tank lining is as follows:

[0054](1) According to the ingredients of the above formula, add fused magnesia aluminum spinel, boric anhydride, and zirconia into a mixer, fully dry mix and evenly prepare a dry blend for use.

[0055] (2) According to the ingredients of the above formula, silica sol, citric acid solution, KH-570 coupling agent and FD35 water reducing agent were prepared into a uniform binder solution for later use.

[0056] (3) Add the prepared dry blend and binder s...

Embodiment 2

[0060] A kind of anti-slag erosion coating for carbon-free inner lining of steel ladle, by weight:

[0061] 70 parts of sintered magnesium aluminum spinel, 5 parts of zirconia, 2 parts of boron carbide, pH=2 (SiO 2 : 20%) of 16 parts of silica sol, 4 parts of tartaric acid solution with pH=4, 2 parts of KH-560 coupling agent, and 1 part of polycarboxylate water reducer FS20.

[0062] A kind of anti-slag corrosion coating for steel ladle carbon-free lining its preparation method is as follows:

[0063] (1) Add the sintered magnesia-alumina spinel, boron carbide, and zirconia into the mixer according to the above-mentioned ingredients, and dry-blend fully and uniformly to prepare a dry-blended material for later use.

[0064] (2) According to the ingredients of the above formula, silica sol, tartaric acid solution, KH-560 coupling agent and FS20 water reducer are prepared into a uniform binder solution for later use.

[0065] (3) Add the prepared dry blend and binder solution ...

Embodiment 3

[0068] A kind of anti-slag erosion coating for carbon-free inner lining of steel ladle, by weight:

[0069] 70 parts of fused magnesium aluminum spinel, 2 parts of zirconia, 3.5 parts of boron nitride, pH=2 (SiO 2 : 40%) of 20 parts of silica sol, 1 part of malic acid solution with pH=1, 1.5 parts of KH-570 coupling agent, 2 parts of sulfonated melamine formaldehyde resin of sulfonic acid water reducer.

[0070] A kind of anti-slag corrosion coating for steel ladle carbon-free lining its preparation method is as follows:

[0071] (1) According to the above formula and ingredients, add fused magnesia aluminum spinel, boron nitride and zirconia into the mixer, fully dry mix and evenly prepare a dry blend for use.

[0072] (2) According to the above formula and ingredients, silica sol, malic acid solution, KH-570 coupling agent and sulfonated melamine formaldehyde resin water reducer were prepared into a uniform binder solution for later use.

[0073] (3) Add the prepared dry b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com