Flame retardant for pvc processing, preparation method thereof, and flame retardant power pipe containing the same

A flame retardant and flame retardant technology, applied in the field of PVC flame retardant, can solve the problems of unable to meet the requirements of inorganic flame retardant coating, limited β-cyclodextrin coating rate, difficulty in inorganic flame retardants, etc., to achieve increased Active loading sites, improved flame retardant effect, improved chelation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Second, the present invention provides a preparation method of a flame retardant for PVC processing, comprising the following steps:

[0038] (1) Weigh the nano-inorganic flame retardant, organically modified cyclodextrin and salts containing flame retardant elements in proportion;

[0039](2) Dissolving the salt containing the flame retardant element in water to form a salt solution, and then immersing the organically modified cyclodextrin in the salt solution, so that the flame retardant element is loaded on the organically modified cyclodextrin, and at the same time adding nanometer The inorganic flame retardants are blended to form a coating liquid, which is uniformly stirred at 25-30° C. and 5000-8000 r / min, and then spray-dried to obtain a flame-retardant coating.

[0040] In the present invention, the mass ratio of the salts of flame retardant elements, water, organically modified cyclodextrin, and nano-inorganic flame retardant is 1-10:100-200:40-60:15-25.

[0...

Embodiment 1

[0047] A flame retardant for PVC processing, and a preparation method thereof, comprising the following steps:

[0048] (1) Preparation of organically modified cyclodextrin

[0049] DMF was placed in an airtight container, and potassium persulfate was added to dissolve after nitrogen removal; acrylonitrile and β-cyclodextrin were dissolved in an organic solvent, blended and treated at elevated temperature (65°C, 5h) to obtain the reaction product. After centrifugation, the product was repeatedly sonicated and dissolved in DMF until the supernatant had no white precipitate. The final product was washed with absolute ethanol and then dried to obtain an intermediate product; the intermediate product was added to 1 mol / L NaOH solution for saponification. After reaction (75°C, 1.5h), centrifugation, and drying (50°C, 4h), polyacrylonitrile saponified modified β-cyclodextrin was obtained. The volume ratio of DMF to acrylonitrile was 6:1, the addition amount of potassium persulfate ...

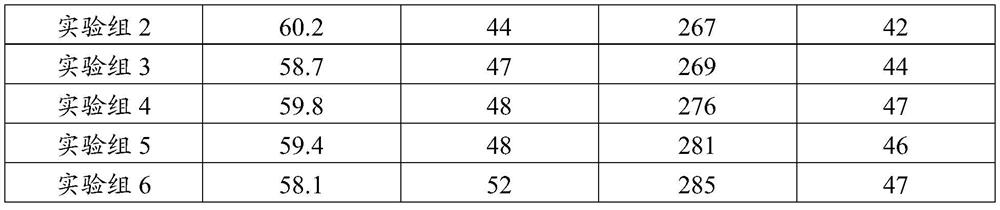

Embodiment 2

[0055] The difference between this example and Example 1 is that the addition amount of magnesium chloride and zinc chloride in (2) is 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com