Method for improving specific capacitance of laser-induced graphene-based capacitor and laser-induced graphene-based capacitor

A laser-induced, graphene-based technology, applied in the field of capacitors, can solve problems such as high production costs, environmental pollution, and complex operations, and achieve the effects of improving efficiency, excellent efficiency, and increasing specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

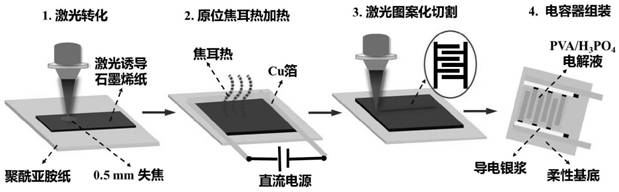

[0054] In the present invention, taking the interdigital electrode as an example, the preparation method of the laser-induced graphene-based capacitor preferably includes the following steps:

[0055] The laser-induced graphene material subjected to Joule heat treatment is patterned and cut to obtain interdigital electrodes;

[0056] Paste the interdigital electrodes on one side of the substrate, paste the current collector on the single side of the substrate to connect the interdigital electrodes, and coat conductive silver glue at the joint between the interdigital electrodes and the current collector, and then An electrolyte solution is coated on the surface of the interdigital electrodes, and dried under vacuum to solidify the electrolyte solution to obtain a laser-induced graphene-based capacitor.

[0057] In the present invention, double-sided tape is preferably used to stick the interdigital electrode and the current collector. In the present invention, the solvent of ...

Embodiment 1

[0063] (1) Using a CO equipped with a wavelength of 10.6 μm 2 Laser irradiation system irradiates polyimide paper (10×5cm 2 ), laser induced under different laser power conditions to obtain laser-induced graphene paper (LIGP); wherein, the operating conditions include: the scanning mode is progressive scanning, the line-by-line scanning scribe spacing is 100 μm, and the scanning rate is 2inch / s, the image density is 1000PPI; the laser power is 1.25W; the laser induction is carried out at room temperature (25°C) and in an atmospheric environment.

[0064] (2) Paste copper foil on the opposite sides of the laser-induced graphene paper, and apply conductive silver glue on the contact between the copper foil and the laser-induced graphene paper to reduce the contact resistance between the two, at room temperature Under the condition, stand until the conductive silver glue is dried to obtain a laser-induced graphene paper heater (such as figure 1 shown).

[0065] (3) Connect the...

Embodiment 2

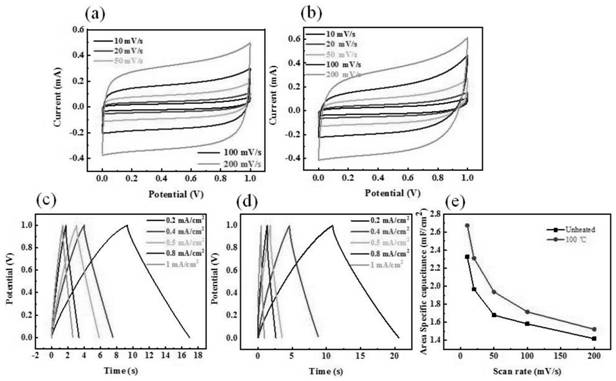

[0072] Example 2 Electrochemical performance test of graphene paper after Joule heat treatment at 100°C for 60min

[0073] according to Figure 12 The flow chart shown is for the fabrication of graphene-based capacitors, including the following steps:

[0074] (1) Using a CO equipped with a wavelength of 10.6 μm 2 Laser irradiation system irradiates polyimide paper (10×5cm 2 ) on the single side of ), carry out laser induction to obtain laser-induced graphene paper; wherein, the operating conditions include: the scanning mode is progressive scanning, the line spacing of progressive scanning is 100 μm, the scanning rate is 2 inch / s, and the image density is 1000 PPI; The laser power was 1.25W; the laser induction was performed at room temperature and in an atmospheric environment.

[0075] (2) Paste copper foil on the opposite ends of the laser-induced graphene paper, and apply conductive silver glue on the contact between the copper foil and the laser-induced graphene paper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com