A method of improving high temperature oxidation resistance of agcu alloy by using three-dimensional network reinforcement phase

A high-temperature oxidation resistance and three-dimensional network technology, which is applied in the field of improving the high-temperature oxidation resistance of AgCu alloys, can solve the problems of poor high-temperature oxidation resistance of silver-copper-based solders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific implementation mode 1: In this implementation mode, the method for improving the high temperature oxidation resistance of AgCu alloy by using the three-dimensional network reinforcement phase is carried out according to the following steps:

[0030] 1. Using the ice template method to prepare the density of 7 ~ 15mg / cm 3 graphene sponge;

[0031] 2. Preparation and molding of AgCuTi solder paste: Mix AgCuTi powder and binder evenly to obtain AgCuTi solder paste, mold the AgCuTi solder paste through a mold to obtain sheet-like solid AgCuTi solder paste;

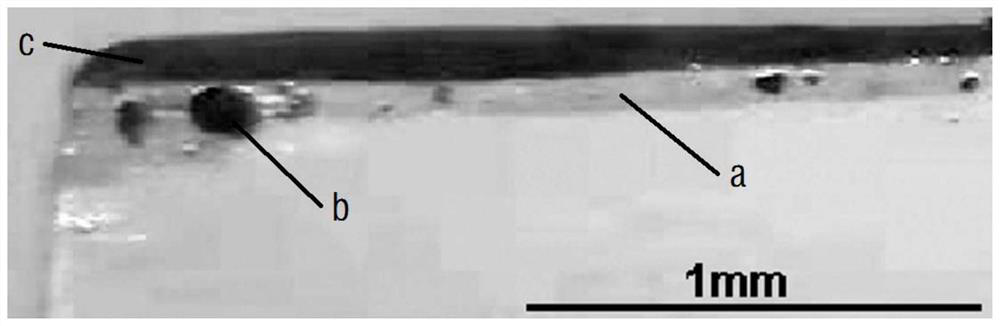

[0032] 3. Assembly of the test piece to be infiltrated: the graphene sponge is placed between two pieces of solid AgCuTi solder paste to obtain the test piece to be infiltrated. The graphite paper in the solid AgCuTi solder paste is located on the upper surface of the test piece to be infiltrated and Lower surface; the surface size of each solid-state AgCuTi solder paste and graphene sponge is identical; the m...

specific Embodiment approach 2

[0040] Specific embodiment two: what this embodiment is different from specific embodiment one is: adopt the ice template method described in step one to prepare the method for graphene sponge to carry out as follows:

[0041] 1) Disperse the graphene oxide powder in deionized water, and ultrasonically treat it at 100KHz for 0.5-1h to obtain a graphene oxide dispersion with a concentration of 2mol / L;

[0042] 2) Put the graphene oxide dispersion into a plastic container and freeze it at -20 to -40°C for 1h to 2h to obtain a mixture of graphene oxide and ice;

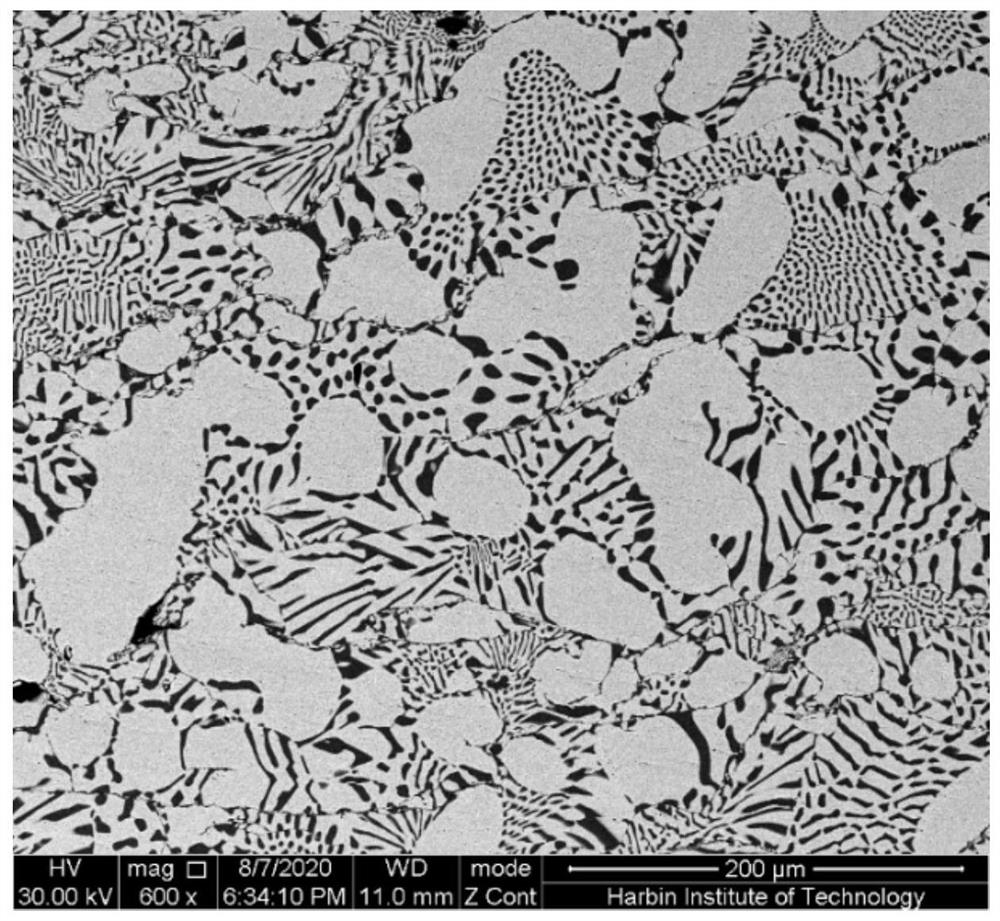

[0043] The graphene oxide dispersion liquid is frozen into ice to obtain a mixture of graphene oxide and ice, and the graphene oxide is distributed in a three-dimensional network at ice grain boundaries.

[0044] 3) Put the mixture of graphene oxide and ice into a freeze dryer, and freeze-dry for 48-96 hours. At this time, the ice in the mixture of graphene oxide and ice is completely sublimated to obtain a graphene oxid...

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the AgCuTi powder described in step two is made by grinding and mixing AgCu eutectic alloy powder and Ti powder, and the mass fraction of Ti in the AgCuTi powder is 3.0~ 6.0 wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com