Welding method of copper-containing corrosion-resistant steel rails

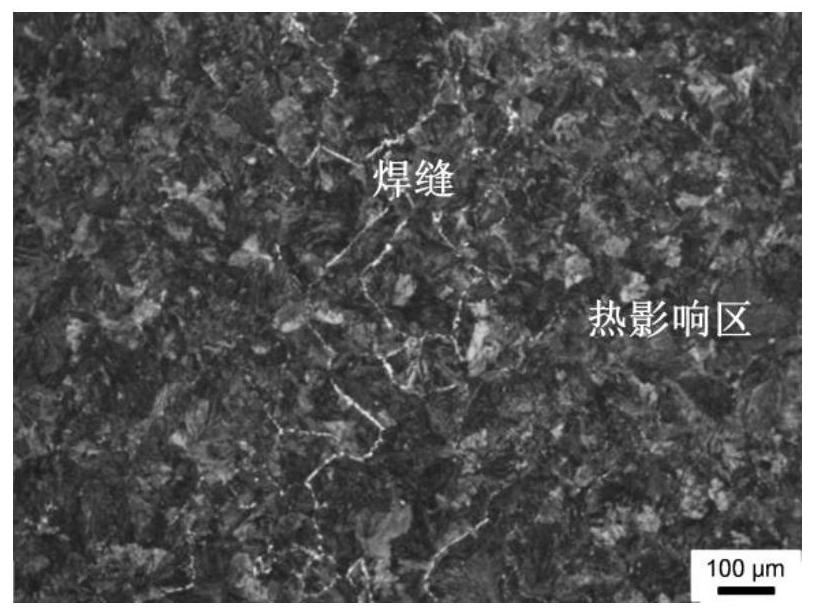

A welding method and corrosion-resistant technology, applied in rails, welding equipment, welding equipment, etc., can solve the problems of affecting service performance, enriching and eroding grain boundaries, endangering driving safety, etc., to reduce the probability of welding gray spots, improve The effect of service safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

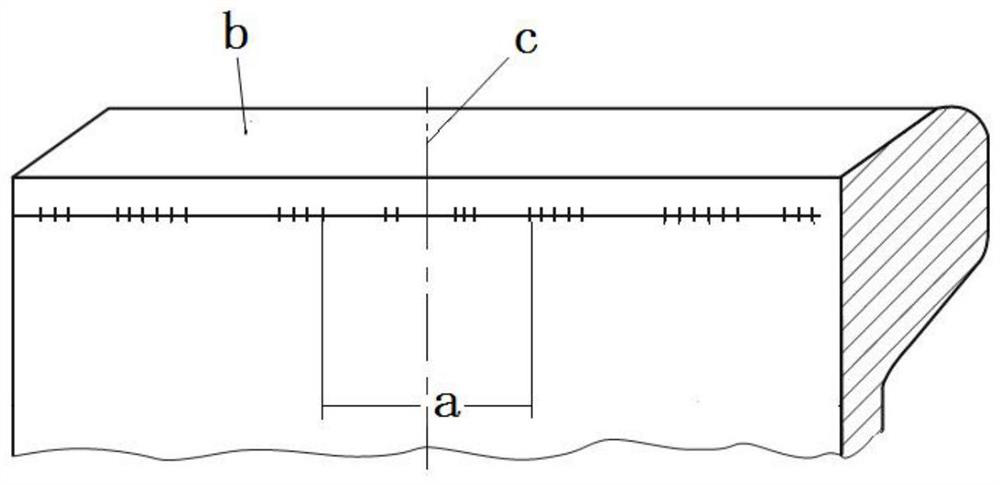

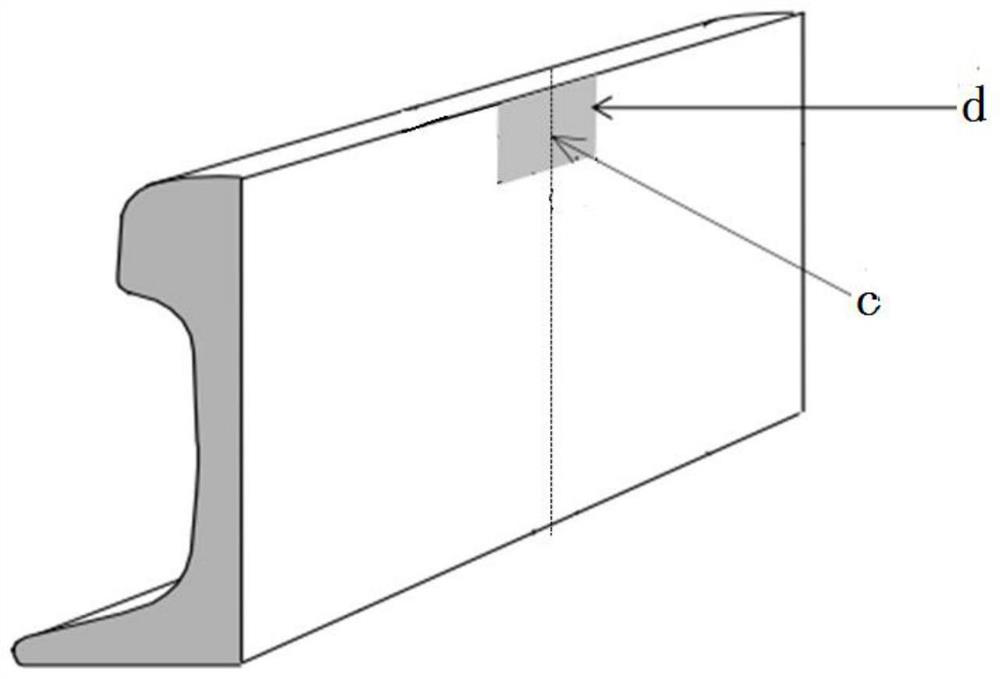

[0045] The microstructure of the rail base metal is controlled to be 90% pearlite and 10% proeutectoid ferrite. The base material has a tensile strength of 1150 MPa and an elongation of 13%. The chemical composition of the rail base metal to obtain the microstructure needs to meet the following conditions: 0.65% content of C, 0.32% content of Si, 1.1% content of Mn, 0.5% content of Cr, 0.06% content of V, 0.20% content Ni, Cu with a content of 0.60%, the balance being Fe and unavoidable impurities. The processing technology of the base metal of the rail to obtain this microstructure needs to meet the following conditions: the billet is heated and rolled into a rail with a single weight of 60kg / m, and then left to cool in the air. Spray cooling medium with a cooling rate of 3.0°C / s to the top surface of the rail head, both sides of the rail head, and the lower jaws on both sides of the rail head, respectively. After reaching 350°C, stop the accelerated cooling and continue air...

Embodiment 2

[0050] The microstructure of the rail base metal is controlled to be 95% pearlite and 5% proeutectoid ferrite. The base material has a tensile strength of 1250 MPa and an elongation of 14%. The chemical composition of the rail base metal to obtain the microstructure needs to meet the following conditions: 0.68% content of C, 0.45% content of Si, 0.90% content of Mn, 0.3% content of Cr, 0.04% content of V, 0.30% content Ni, Cu with a content of 0.40%, the balance being Fe and unavoidable impurities. The processing technology of the base metal of the rail to obtain this microstructure needs to meet the following conditions: the steel billet is heated and rolled into a rail with a single weight of 60kg / m, and then left to cool in the air. The cooling medium with a cooling rate of 6.0°C / s was sprayed to the top surface of the rail head, both sides of the rail head and the lower jaws on both sides of the rail head respectively. After reaching 400°C, the accelerated cooling was sto...

Embodiment 3

[0055] The microstructure of the control rail base metal is 99% pearlite and 1% proeutectoid ferrite, the tensile strength is 1220MPa, and the elongation is 15%. The chemical composition of the rail base metal to obtain the microstructure needs to meet the following conditions: 0.76% content of C, 0.60% content of Si, 0.85% content of Mn, 0.4% content of Cr, 0.04% content of V, 0.25% content Ni, 0.35% Cu, the balance Fe and unavoidable impurities. The processing technology of the rail steel with this microstructure needs to meet the following conditions: the billet is heated and rolled into a rail with a single weight of 60kg / m, and then cooled in the air. When the temperature at the center of the top surface of the rail head drops to 830°C, Spray a cooling medium with a cooling rate of 5.5°C / s to the top surface of the rail head, both sides of the rail head and the lower jaws on both sides of the rail head. After reaching 400°C, stop the accelerated cooling and continue air c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com