Air-cooling type 80H thermal production well casing based on strain design and production process thereof

A thermal recovery well and air-cooling technology, which is applied in the field of oil pipes, can solve problems such as oil casing pipe safety hazards, plastic strain accumulation damage, etc., and achieve the effects of improving resistance to high temperature permanent deformation, reducing plastic deformation, and reducing casing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

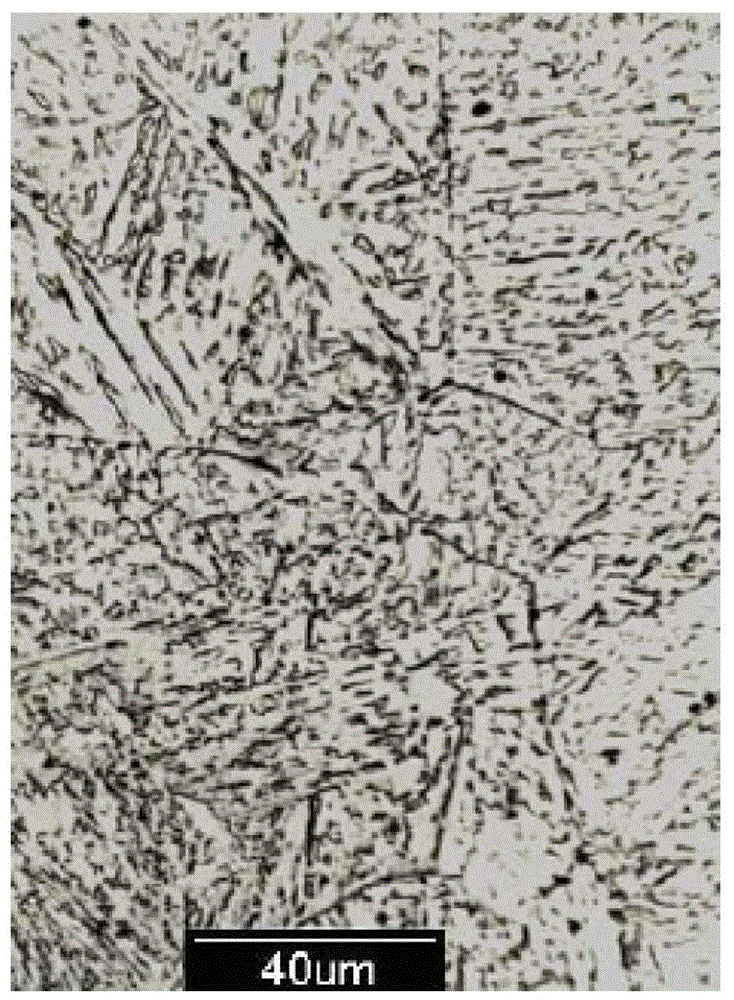

Image

Examples

Embodiment 1

[0014] The air-cooled 80H thermal recovery well casing provided based on the strain design provided in Example 1 of the present invention has the mass percentages of the chemical components of the materials as follows:

[0015] C: 0.20%, Mn: 1.15%, Si: 0.42%, P: <0.011%, S: <0.004%, Cr: 0.99%, Mo: 0.22%, Ni: 0.03%, Nb: 0.016%, Al: 0.012 %, B: 0.001%, the rest is the matrix element iron.

[0016] The effect of each component in the material of the air-cooled 80H thermal recovery well casing provided based on casing string strain design provided in Example 1 of the present invention is as follows:

[0017] The role of the C element is mainly to increase the strength. Under the premise of ensuring the necessary strength of the steel, the carbon content should be reduced as much as possible to improve the plasticity and toughness of the material.

[0018] The addition of the Mn element not only plays a role of solid solution strengthening, but also can refine the structure of the...

Embodiment 2

[0041] The air-cooled 80H thermal recovery well casing provided based on the strain design provided by Embodiment 2 of the present invention has the mass percentages of the chemical components of the materials as follows:

[0042]C: 0.21%, Mn: 1.22%, Si: 0.43%, P: <0.011%, S: <0.004%, Cr: 0.96%, Mo: 0.23%, Ni: 0.032%, Nb: 0.014%, Al: 0.016 %, B: 0.0012%, and the rest is the matrix element iron.

[0043] In the production process of the air-cooled 80H thermal recovery well casing based on the strain design provided by Embodiment 2 of the present invention, in the heat treatment process, after the austenite is deformed and relaxed in the non-recrystallized zone for 25s, air cooling is adopted; cooling The speed is controlled at 8°C / s.

[0044] The test results of the characteristic parameters of the air-cooled 80H thermal recovery well casing based on the strain design provided in Example 2 of the present invention are as follows:

[0045] Yield strength σ s =627MPa;

[0046...

Embodiment 3

[0052] The air-cooled 80H thermal recovery well casing provided based on the strain design provided by Example 3 of the present invention has the mass percentages of the chemical components of the materials as follows:

[0053] C: 0.22%, Mn: 1.06%, Si: 0.42%, P: <0.011%, S: <0.004%, Cr: 0.95%, Mo: 0.25%, Ni: 0.032%, Nb: 0.014%, Al: 0.013 %, B: 0.001%, the rest is the matrix element iron.

[0054] In the production process of the air-cooled 80H thermal recovery well casing based on the strain design provided by Embodiment 2 of the present invention, in the heat treatment process, after the austenite is deformed and relaxed in the non-recrystallized zone for 30 seconds, air cooling is used; cooling The speed is controlled at 10°C / s.

[0055] The test results of the characterization parameters of the air-cooled 80H thermal recovery well casing based on the strain design provided in Example 3 of the present invention are as follows:

[0056] Yield strength σ s =629MPa;

[0057...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com