High-temperature and high-pressure circulating water constant-load extension experimental device with acoustic emission testing function

A high-temperature, high-pressure, experimental device technology, applied in the field of material experiments, can solve problems such as the acquisition of data by acoustic emission probes, achieve the effects of accurate experiments, simplify device design, and improve service safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

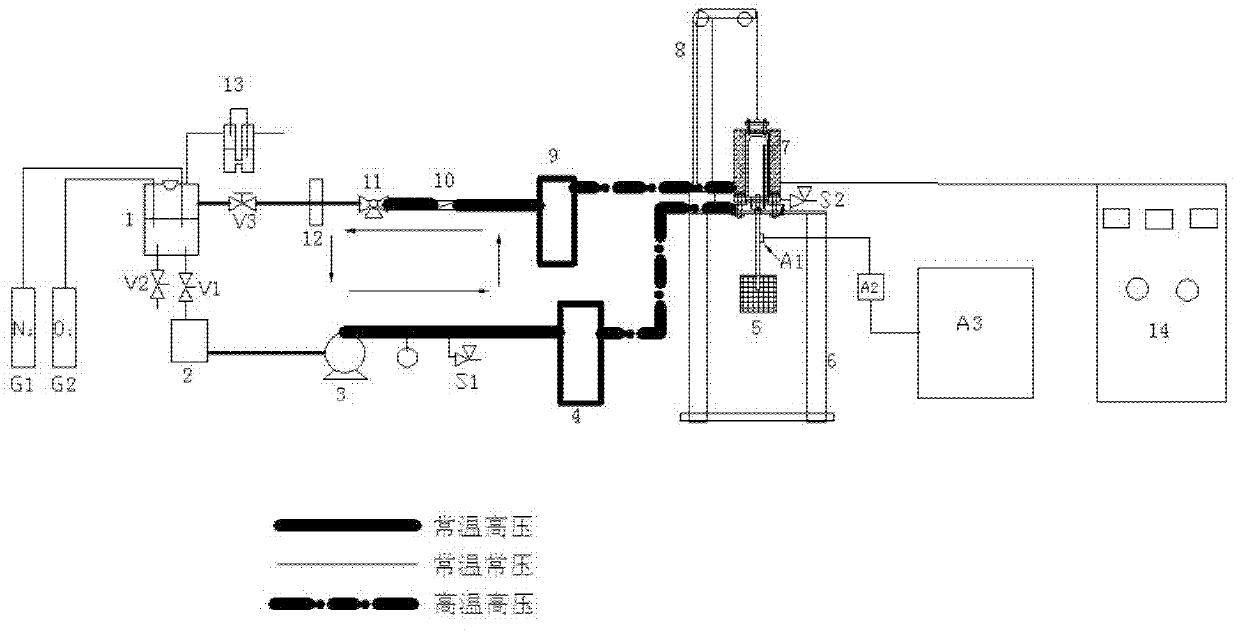

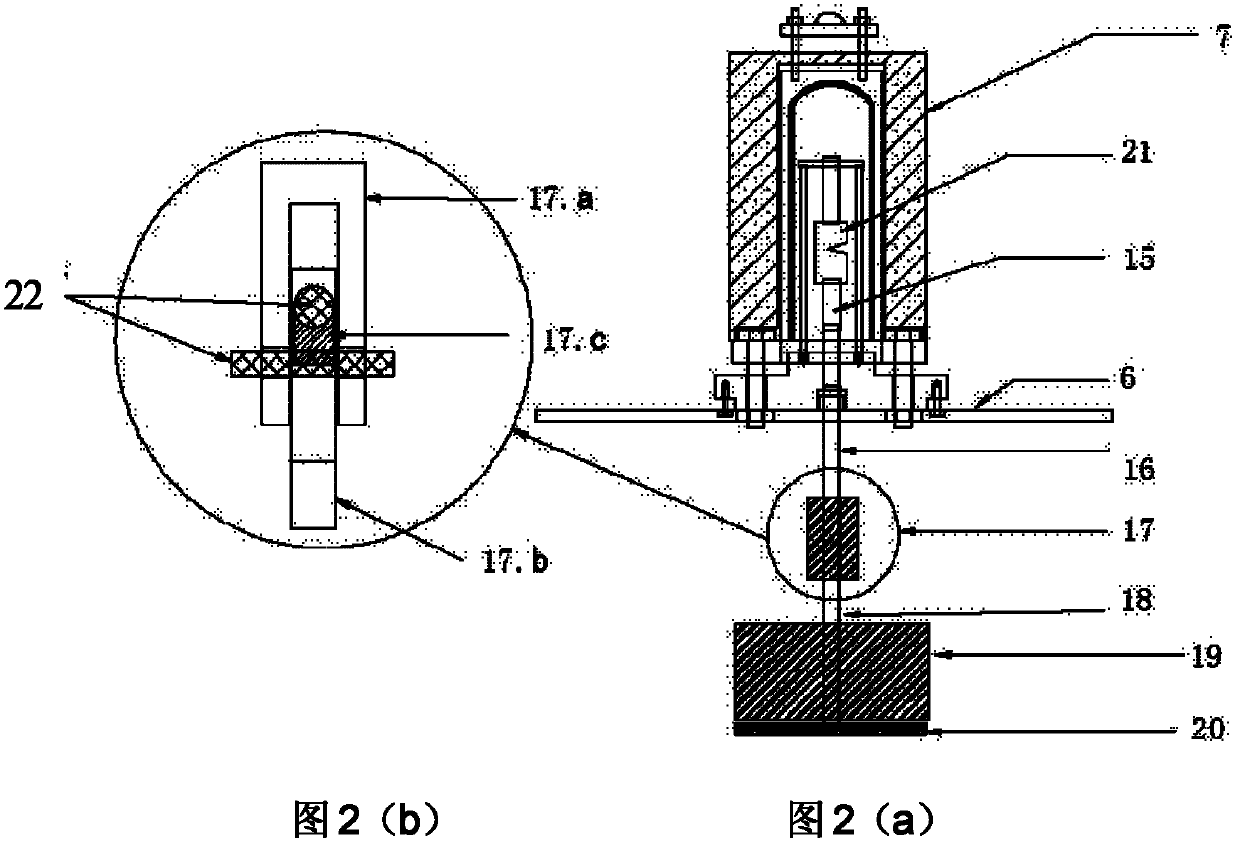

Method used

Image

Examples

Embodiment

[0056] Constant load tensile test of domestic nuclear grade 304 stainless steel in 300°C, 10MPa, high temperature and high pressure circulating water saturated with dissolved oxygen (DO).

[0057] The experimental material is domestic nuclear grade 304 stainless steel, the sample is processed into a compact tensile sample, the sample width W=20mm, the sample thickness B=10mm, and pure water is injected into the water storage tank. Fix the sample on the fixture, tighten the autoclave, and place a 350kg weight on the chassis. Fix the acoustic emission probe on the waveguide rod, that is, the loading axis I, start the high-temperature and high-pressure circulating water control cabinet, and start the high-pressure pump. When the water flows back to the water storage tank, then adjust the back pressure valve to keep the pressure constant at 10MPa, set the temperature of the preheater to 300°C, set the temperature of the autoclave to 300°C, start the heating switch, open the acoust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com