Printing plate protective coating and preparation method thereof

A protective coating and printing plate technology, which is applied in the field of printing plate protective coating and its preparation, can solve the problems that the printing plate does not have comprehensive properties, achieve good chemical inertness and thermal stability, large bond energy, and surface friction coefficient small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

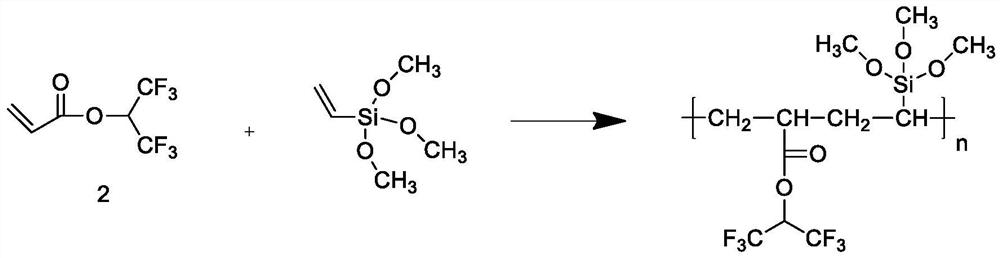

[0036] Described modified acrylic resin is prepared by the following steps:

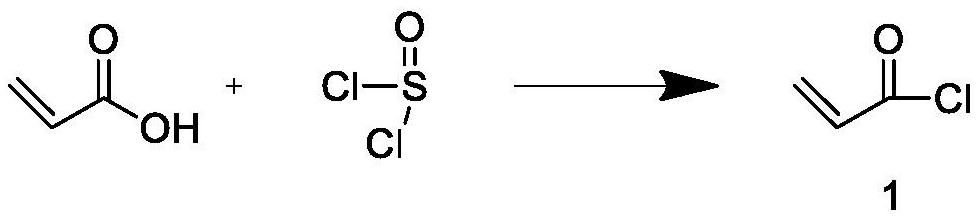

[0037] Step A1: Take a three-necked flask equipped with a stirrer and a thermometer, add acrylic acid to the three-necked flask, then add thionyl chloride to the three-necked flask, control the stirring speed to 500r / min, and the reaction temperature to 55°C for 40 minutes. Intermediate 1 was prepared, wherein the ratio of acrylic acid to thionyl chloride was 1 mol: 1.15 mol;

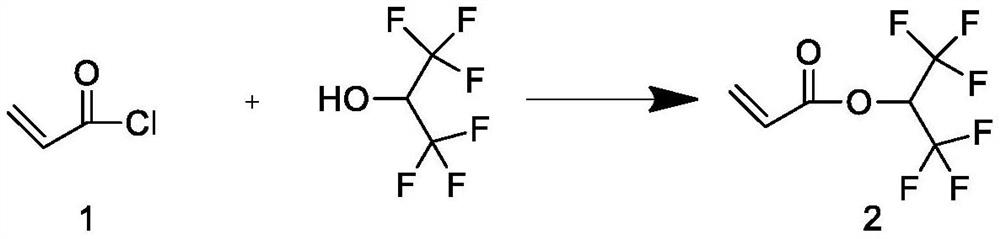

[0038] Step A2: Mix hexafluoroisopropanol and tetrahydrofuran into a three-necked flask, add aqueous sodium hydroxide solution to the three-necked flask, adjust the pH value of the mixture to 10, and stir at a stirring speed of 120r / min and a water bath temperature of 45°C , using a dropping funnel to add intermediate 1 dropwise to a three-necked flask, after the dropwise addition, keep the temperature for 1 hour, wash the reaction mixture with deionized water, leave it to separate layers, and remove the oily liquid in the low...

Embodiment 2

[0041] Described modified acrylic resin is prepared by the following steps:

[0042] Step A1: Take a three-necked flask equipped with a stirrer and a thermometer, add acrylic acid to the three-necked flask, then add thionyl chloride to the three-necked flask, control the stirring speed to 600r / min, and the reaction temperature to 56°C for 45 minutes. Intermediate 1 was prepared, wherein the ratio of acrylic acid to thionyl chloride was 1 mol: 1.15 mol;

[0043] Step A2: Mix hexafluoroisopropanol and tetrahydrofuran into a three-necked flask, add aqueous sodium hydroxide solution to the three-necked flask, adjust the pH value of the mixture to 10, and stir at a stirring speed of 130r / min and a water bath temperature of 48°C , using a dropping funnel to drop intermediate 1 into a three-necked flask. After the dropwise addition, keep the temperature for 1.2 hours, wash the reaction mixture with deionized water, let it stand for layers, and remove the oily liquid in the lower layer ...

Embodiment 3

[0046] Described modified acrylic resin is prepared by the following steps:

[0047] Step A1: Take a three-necked flask equipped with a stirrer and a thermometer, add acrylic acid to the three-necked flask, then add thionyl chloride to the three-necked flask, control the stirring speed to 700r / min, and the reaction temperature to 58°C for 50 minutes. Intermediate 1 was prepared, wherein the ratio of acrylic acid to thionyl chloride was 1 mol: 1.15 mol;

[0048] Step A2: Mix hexafluoroisopropanol and tetrahydrofuran into a three-necked flask, add aqueous sodium hydroxide solution to the three-necked flask, adjust the pH value of the mixture to 10, and stir at a stirring speed of 150r / min and a water bath temperature of 50°C , use a dropping funnel to drop intermediate 1 into a three-necked flask. After the dropwise addition is completed, keep the temperature for 1.5 hours, wash the reaction mixture with deionized water, let it stand for layers, and remove the oily liquid in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com