Discharge separation and concentrated transportation device of punching machine

A technology of stamping machine tools and separation sets, applied in the direction of stripping devices, feeding devices, positioning devices, etc., can solve the problems of multiple workers, low efficiency, and inability to improve machine tools, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

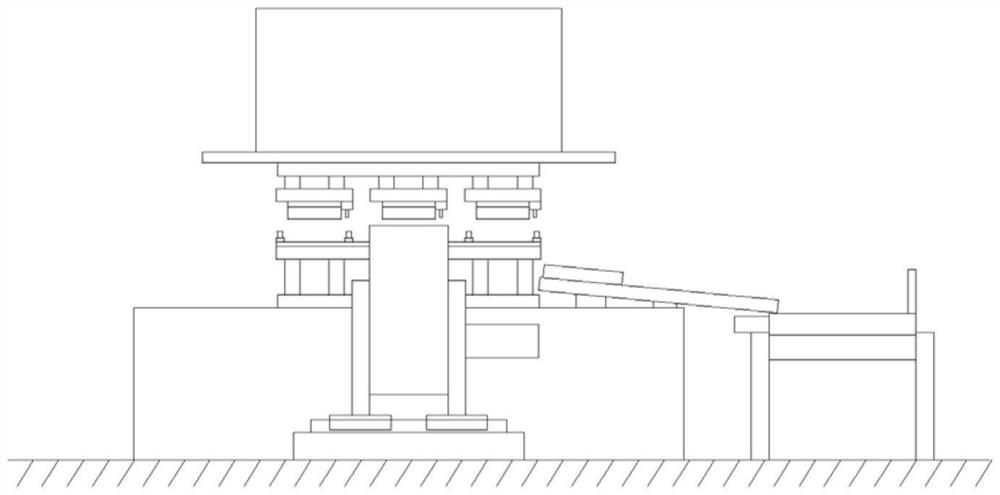

[0036] The purpose of this embodiment is to provide a solution for unloading or unloading with a certain degree of automation, which replaces the only operating table / table used to clean the punching machine.

[0037] The usage method of this embodiment is as follows:

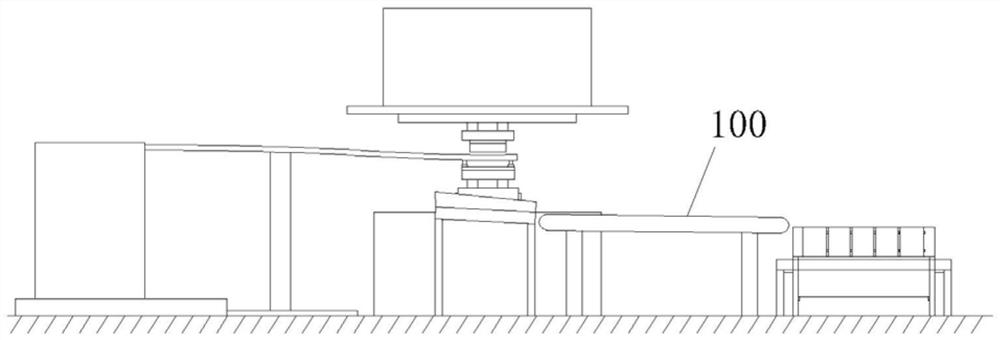

[0038] 1. According to the size of the finished stamping part, start the power mechanism 5 in advance to adjust the height of the telescopic mechanism 6 to ensure that it can hold the stamping part;

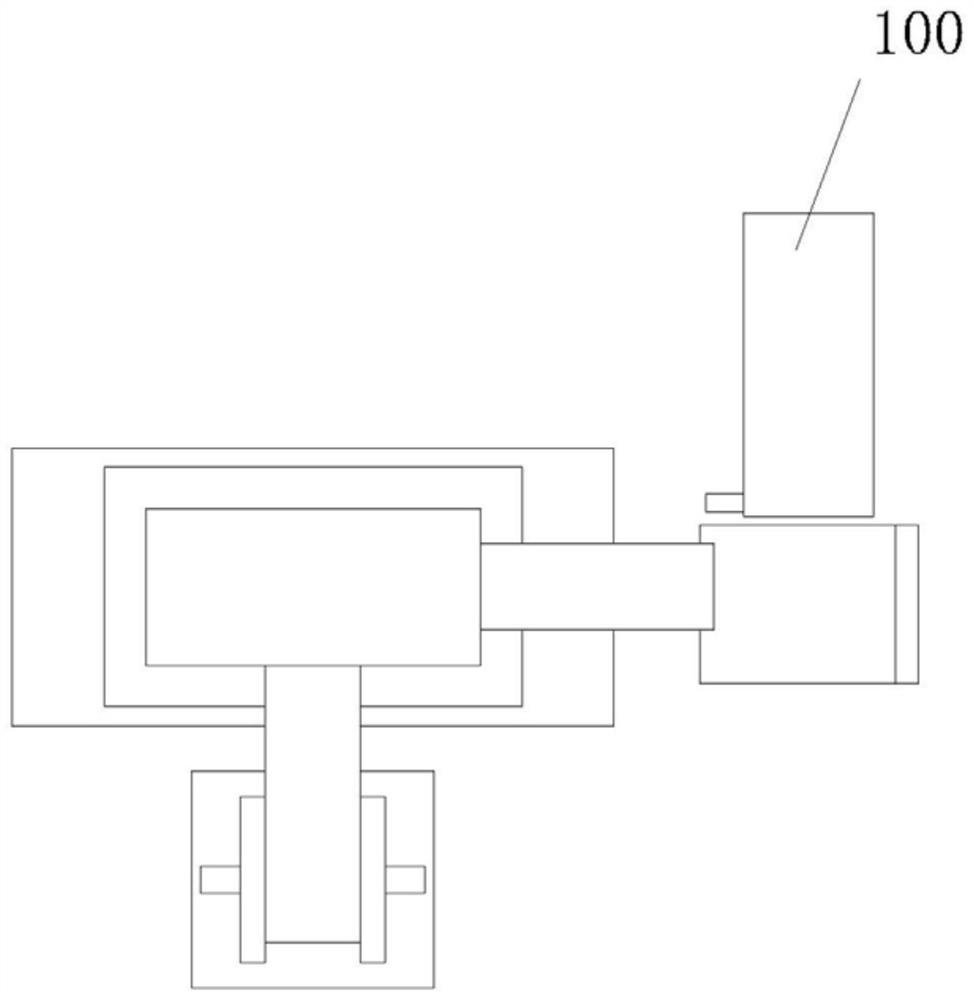

[0039] 2. After the stamping parts are processed, the feeding mechanism of the stamping machine itself transports the processed stamping parts to the slide table 100, and the stamping parts fall under the action of gravity;

[0040] 3. The worker feeds the stamped parts that have fallen from the sliding table 100 into the through hole 4 of the first base 3 of the cleaning module 1, and starts the telescopic mechanism 6, which stretches out to clamp the stamped parts;

[0041] 4. Start the sliding mechanism 10 of ...

Embodiment 2

[0057] This embodiment is made on the basis of the first embodiment, on which a water spray mechanism is added to spray liquid that can play a cleaning role toward the stamping parts before the wiping plate 9 is cleaned, assisting in cleaning work.

[0058] The water guide bar 12 is similar to common industrial wind knives, and is in the shape of a column. A notch 16 is provided on the side of the wiping plate 9 facing the through hole 4 or toward the side of the clamping assembly, exposing the bracket plate 8 . Fix the water guide strip 12 on the bracket plate 8, ensure that the water guide strip 12 is closer to the stamping part than the wiping plate 9, and spray the liquid on the stamping part first. A water channel 16 is provided in the water guide bar 12, and the water channel 16 is arranged along its length direction. The water outlet hole 14 on the side wall of the water guide bar 12 is connected to the water channel, and the water injection interface 13 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com