Hydrogen sensitive element and preparation method thereof

A sensitive element, hydrogen technology, applied in the field of hydrogen sensors, can solve the problems of inaccurate detection of hydrogen, slow response speed of hydrogen, damage to hydrogen dissociation, etc., and achieve the effect of increased signal amplitude, high hydrophobicity, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

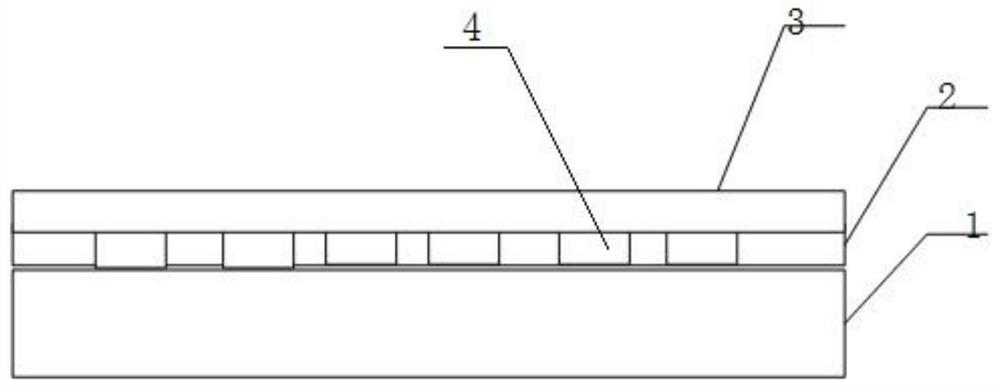

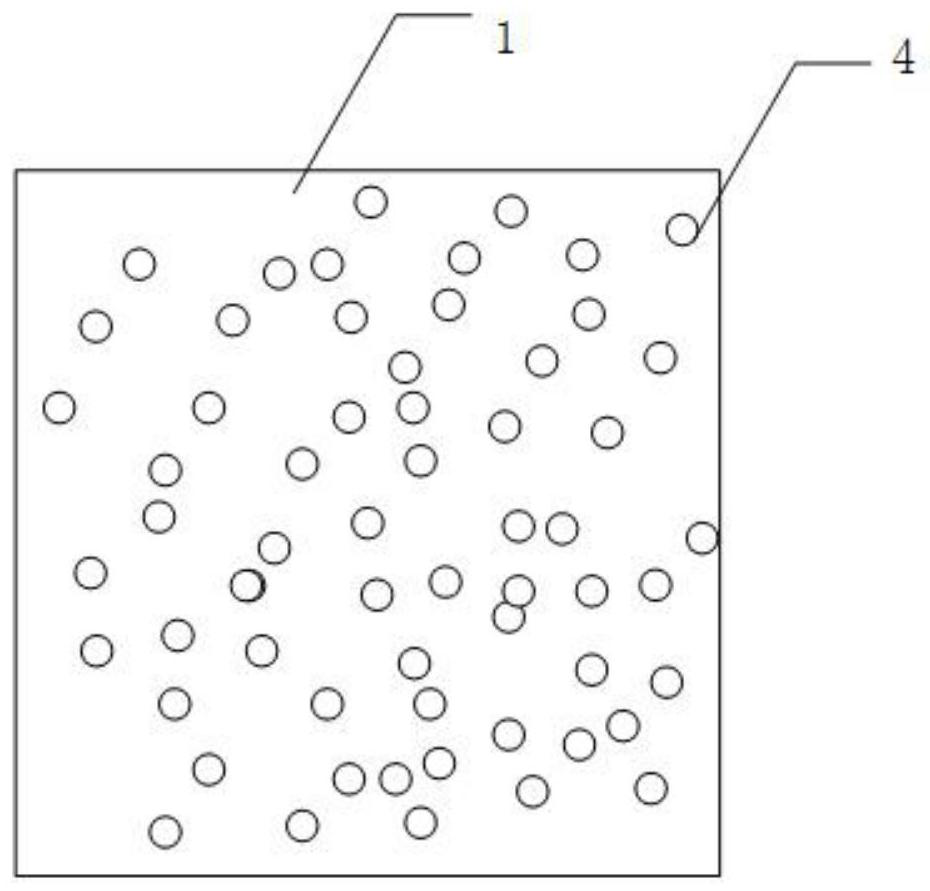

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

[0033] A method for preparing a hydrogen sensitive element, comprising the following steps:

[0034] (1) Clean and dry the glass substrate for later use; the glass substrate is a block of 1cm*1cm, and the cleaning and drying steps are as follows: put the glass substrate in acetone, isopropanol and deionized water for ultrasonic cleaning, and the ultrasonic time is 10 ~ 20min, then dry the glass substrate with nitrogen.

[0035] The substrate can also choose other common polymer flexible materials, such as plexiglass PMMA, PS, PC, PET, FEP, etc.

[0036] (2) Polytetrafluoroethylene is coated on the glass substrate to form the glass substrate with polytetrafluoroethylene film; Spin coating, wherein the coating time is 20-40s, the thickness of the polytetrafluoroethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com