Magnetic reduced graphene oxide/silver tungstate composite photocatalyst as well as preparation method and application thereof

A technology of graphene and silver tungstate, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of poor biocompatibility and difficult recycling of catalysts , to achieve good adsorption performance, slow down recombination, and expand the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

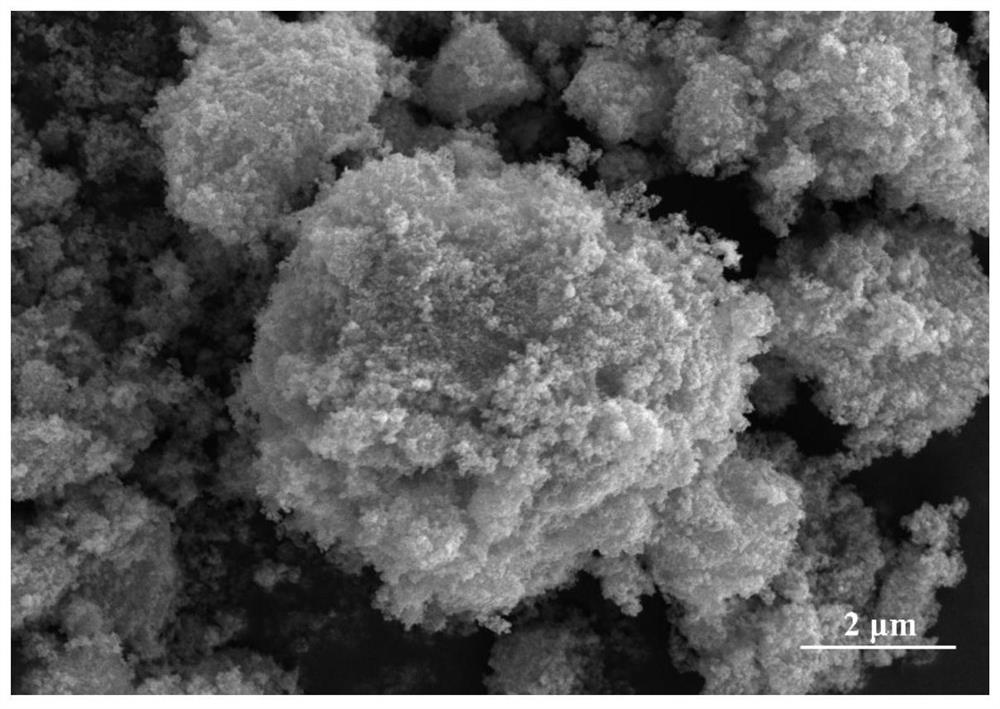

[0042] MrGO / Ag prepared in this example 2 WO 4 In the composite catalyst, x=0.5, and the specific preparation steps are as follows:

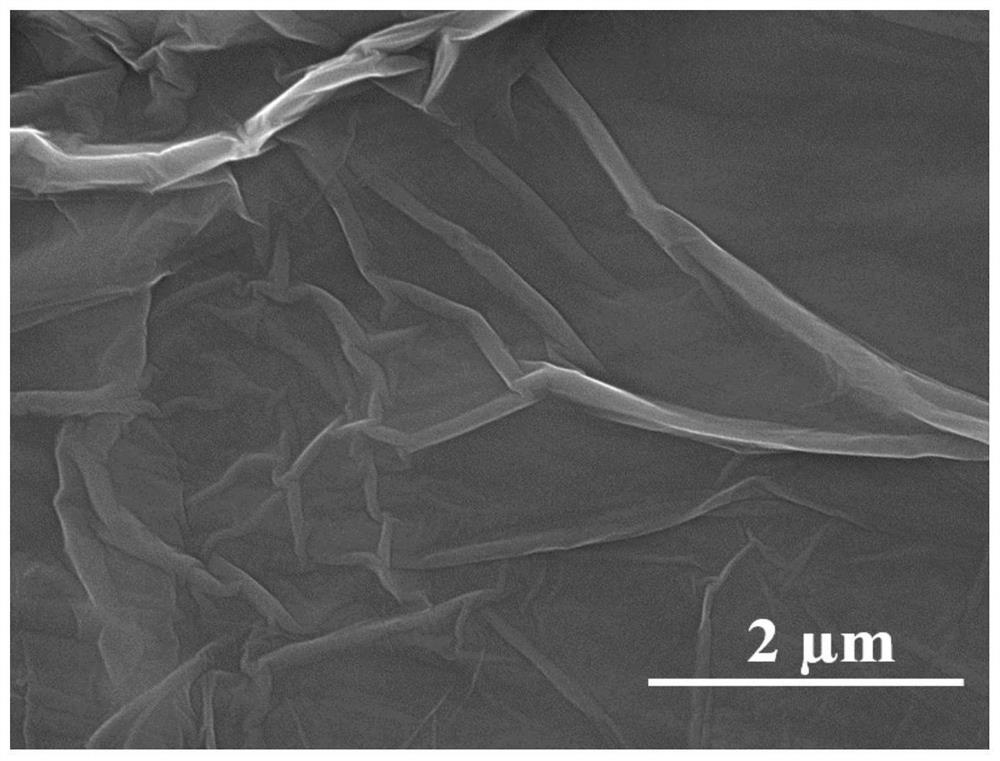

[0043] a) Weigh 2 g of graphite powder, 1 g of sodium nitrate, 3 g of potassium permanganate and 50 mL of concentrated sulfuric acid in a conical flask, react in an ice-water bath for 2 h, then heat up to 40 °C for 40 min for pre-reaction. Add cold deionized water into the Erlenmeyer flask, raise the temperature to 98 °C and continue heating for 20 min, add hydrogen peroxide to oxidize, wash with deionized water three times, wash with absolute ethanol twice, and vacuum-dry at 60 °C to obtain tablets like graphene oxide (GO).

[0044] b) Weigh 0.3 g flake graphene oxide in 60 mL water for 30 min and stir until completely dissolved to form a uniform graphene oxide solution. Take 8.109 g FeCl3 •6H 2 O and 4.17 g FeSO 4 •7H 2 Dissolve O in a three-neck flask in 40 mL of water and fill with N 2 protection, after heating up to 50°C, quickly add...

Embodiment 2

[0047] The magnetic MrGO / Ag prepared in this embodiment 2 WO 4 In the composite catalyst, x=0.2, and the specific preparation steps are as follows:

[0048] a) Weigh 2 g of graphite powder, 1 g of sodium nitrate, 3 g of potassium permanganate and 50 mL of concentrated sulfuric acid in an Erlenmeyer flask, react in an ice-water bath for 1.5 h, then heat up to 35 °C for 30 min for pre-reaction. Add cold deionized water into the Erlenmeyer flask, raise the temperature to 98 °C and continue heating for 20 min, add hydrogen peroxide to oxidize, wash with deionized water three times, wash with absolute ethanol twice, and vacuum dry at 60 °C to obtain flake oxidation Graphene (GO).

[0049] b) Weigh 0.3 g flake graphene oxide in 60 mL water for 30 min and stir until completely dissolved to form a graphene oxide solution. Take 8.109 g FeCl 3 •6H 2 O and 4.17 g FeSO 4 •7H 2 Dissolve O in a three-neck flask in 40 mL of water and fill with N 2 Protection, ammonia water added quic...

Embodiment 3

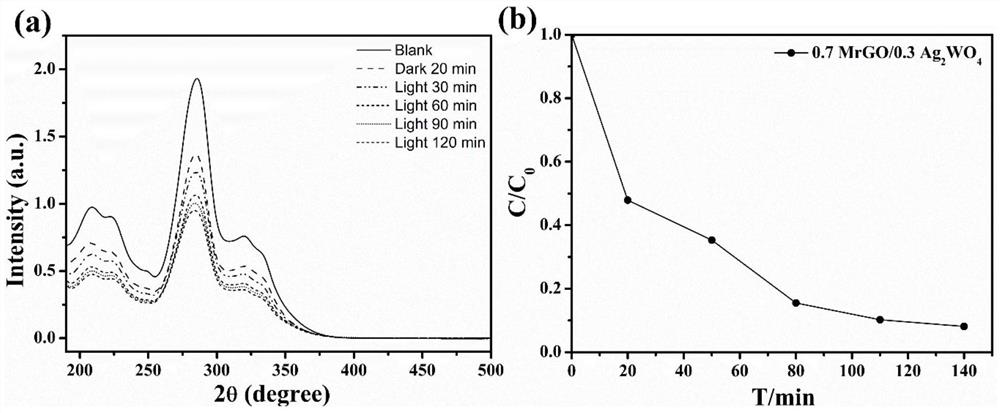

[0052] The magnetic MrGO / Ag prepared in this embodiment 2 WO 4 In the composite catalyst, x=0.5, and it is used to degrade lomefloxacin antibiotics. Concrete preparation steps are as follows:

[0053] a) Weigh 2 g of graphite powder, 1 g of sodium nitrate, 3 g of potassium permanganate and 50 mL of concentrated sulfuric acid in a conical flask, react in an ice-water bath for 2 h, then heat up to 40 °C for 40 min for pre-reaction. Add cold deionized water into the Erlenmeyer flask, raise the temperature to 98 °C and continue heating for 20 min, add hydrogen peroxide to oxidize, wash with deionized water three times, wash with absolute ethanol twice, and vacuum dry at 60 °C to obtain flake oxidation Graphene (GO).

[0054] b) Weigh 0.3 g flake graphene oxide in 60 mL water for 30 min and stir until completely dissolved to form a graphene oxide solution. Take 8.109 g FeCl 3 •6H 2 O and 4.17 g FeSO 4 •7H 2 O in a three-hole flask, dissolved in 40 mL of water and filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com