Aluminum-silicon alloy cover plate material for electronic packaging and preparation method thereof

An aluminum-silicon alloy, electronic packaging technology, applied in the fields of metallurgy and rolling processing, can solve the problems of weak packaging, poor material surface quality, open welding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

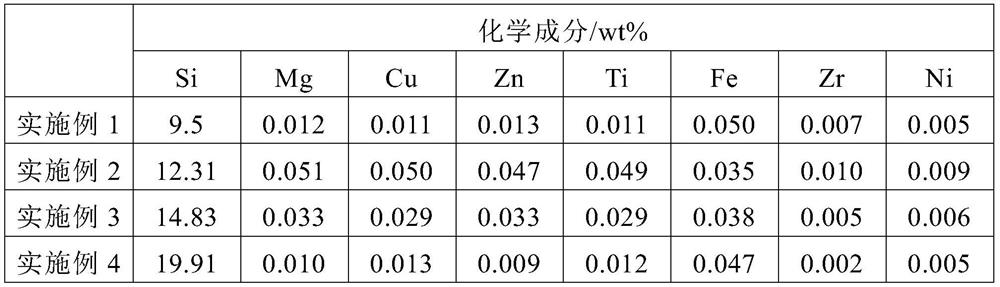

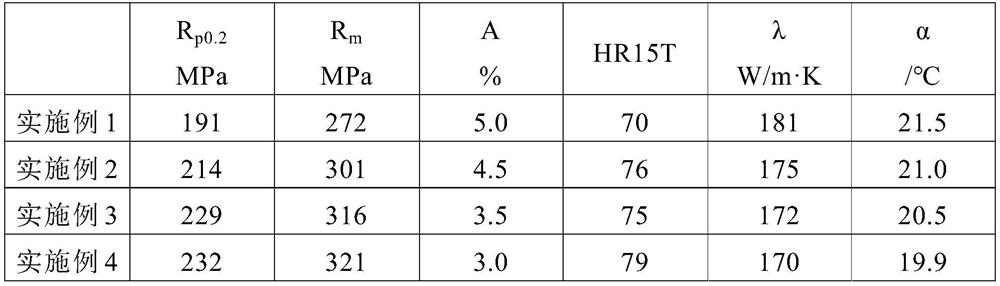

Embodiment 1

[0059] The furnace weight during semi-continuous casting is 100kg.

[0060] Weigh 10kg of Si, 0.01kg of Mg, 0.01kg of Cu, 0.01kg of Zn, 0.01kg of Ti, and 89.96kg of Al into the graphite crucible of the semi-continuous casting machine, adopt intermediate frequency induction melting, after the metal is completely melted, refining and degassing, Start the casting device, use the seed rod to introduce the melt into the graphite mold, the melting temperature is 700°C, and the casting speed is 3mm / s. Cast a billet with a diameter of Φ165.0mm and a length of about 2m.

[0061] The obtained billet is sawed into 200mm long rod ingots, peeled off and then extruded.

[0062] Place the rod ingot in a heat treatment furnace, raise the temperature to 440°C, and heat it for homogenization for 12 hours. Use a 1250-ton forward extrusion machine to extrude the billet into a slab of ≠10mm×200mm, with an extrusion temperature of 450°C, an extrusion speed of 15mm / s, and an extrusion pressure of ...

Embodiment 2

[0066] The furnace weight during semi-continuous casting is 100kg.

[0067] Weigh 12kg of Si, 0.05kg of Mg, 0.05kg of Cu, 0.05kg of Zn, 0.05kg of Ti, and 87.8kg of Al into the graphite crucible of the semi-continuous casting machine, adopt intermediate frequency induction melting, after the metal is fully melted, refining and degassing, Start the casting device, use the seed rod to introduce the melt into the graphite mold, the melting temperature is 720°C, and the casting speed is 4mm / s. Cast a billet with a diameter of Φ165.0mm and a length of about 2m.

[0068] The obtained billet is sawed into 200mm long rod ingots, peeled off and then extruded.

[0069] Place the ingot in a heat treatment furnace, raise the temperature to 430° C., and heat the homogenized heat treatment for 12 hours. Use a 1250-ton forward extrusion machine to extrude the billet into a slab of ≠10mm×220mm, with an extrusion temperature of 450°C, an extrusion speed of 20mm / s, and an extrusion pressure of...

Embodiment 3

[0073] The furnace weight during semi-continuous casting is 100kg.

[0074] Weigh 15kg of Si, 0.03kg of Cu, 0.03kg of Zn, 0.03kg of Ti, 0.03kg of Mg, and 84.88kg of Al into the graphite crucible of the semi-continuous casting machine, adopt medium frequency induction melting, after the metal is fully melted, refining and degassing, Start the casting device, use the seed rod to introduce the melt into the graphite mold, the melting temperature is 750°C, and the casting speed is 3mm / s. Cast a billet with a diameter of Φ165.0mm and a length of about 2m.

[0075] The obtained billet is sawed into 200mm long rod ingots, peeled off and then extruded.

[0076] Place the ingot in a heat treatment furnace, raise the temperature to 450°C, and heat it for homogenization for 12 hours. Use a 1250-ton forward extrusion machine to extrude the billet into a slab of ≠7mm×200mm, the extrusion temperature is 450°C, the extrusion speed is 15mm / s, and the extrusion pressure is 22MPa;

[0077] R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com