Novel composite emulsifier for emulsion explosive

A technology of composite emulsifier and emulsified explosive, which is applied in the direction of non-explosive/non-thermal agent components, explosives, offensive equipment, etc., and can solve problems such as failure, large molecular weight, and high requirements for production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

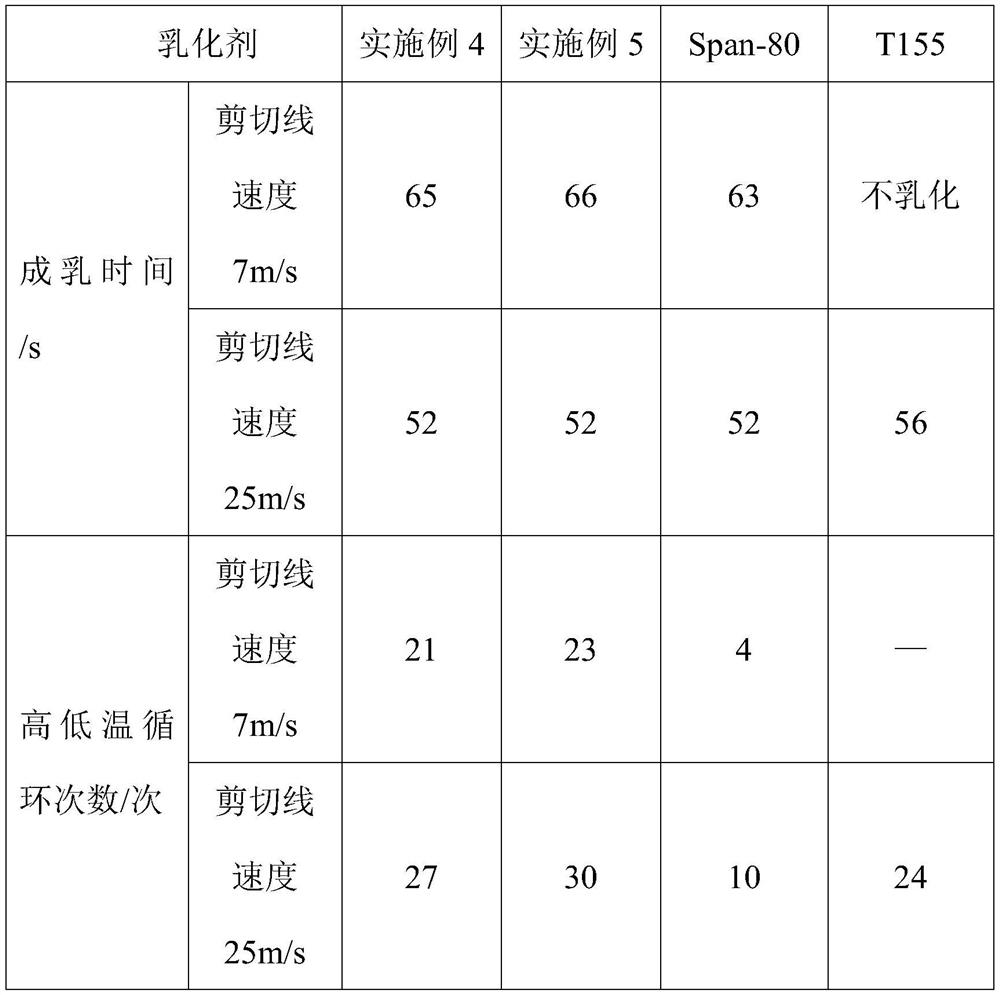

Examples

Embodiment 1

[0025] Preparation of polyisobutylene succinic anhydride:

[0026] Add 2000g (2.0mol) highly active polyisobutene (number average molecular weight 1000, α olefin content ≥ 85wt%) into a 5000ml stainless steel autoclave, protect with nitrogen, stir and heat up to 200°C; 353 g (3.6 mol) of molten maleic anhydride were slowly added dropwise. After the dropwise addition, the temperature in the reactor was slowly raised to 230°C, and the reaction was continued at this temperature for 4 hours. After the reaction, nitrogen was blown into the reactor, and the unreacted maleic anhydride was blown out of the reactor; Detect, the saponification value of reaction product is 112mgKOH / g.

Embodiment 2

[0028] Preparation of polyalphaolefin succinic anhydride:

[0029] In a 500ml four-necked glass bottle, add 300g of PAO40, stir and heat up to 130-180°C, drop 35g of molten maleic anhydride and 7ml of di-tert-butyl peroxide initiator into the reaction system simultaneously within 100min . After the maleic anhydride and the initiator are added dropwise, the reaction is continued for 1 hour at a temperature of 130-180° C. to ensure that the reaction is complete. After the reaction is over, the decomposition products of di-tert-butyl peroxide and unreacted maleic anhydride in the four-neck flask are separated by vacuum distillation in the temperature range of 70-110°C to obtain the reaction Product; After testing, the saponification value of the reaction product is 113.4mgKOH / g.

Embodiment 3

[0031] Preparation of Component B:

[0032] In a 500ml four-necked glass bottle, 141.23g (0.5mol) of oleic acid and 52.57g (0.5mol) of diethanolamine were stirred and heated to 130-190°C, and the reaction was continued for 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com