Environment-friendly toughening furnace and toughened glass processing technology

A kind of tempering furnace, environmental protection technology, applied in glass tempering, glass manufacturing equipment, glass transportation equipment and other directions, can solve the problems of self-explosion of tempered glass, energy load, energy leakage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

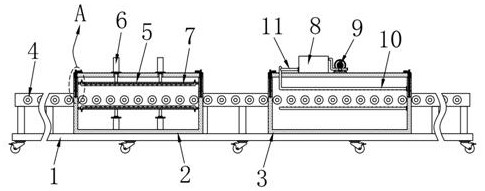

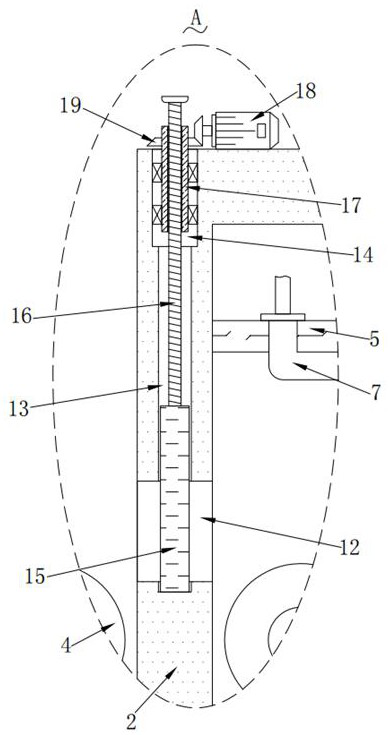

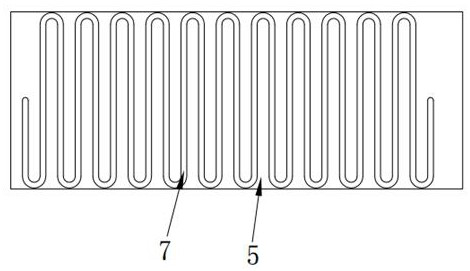

[0027] Please refer to Figure 1-Figure 3 ,in, figure 1 A schematic structural view of a preferred embodiment of the environment-friendly tempering furnace provided by the present invention; figure 2 for figure 1 Schematic enlarged structure of part A shown in ; image 3 It is a schematic diagram of the top view assembly structure of the slide plate and the heating assembly in the present invention.

[0028] The processing technology of the environment-friendly tempering furnace and tempered glass includes: a support 1; a heating chamber 2, the heating chamber 2 is arranged on the support 1; a cooling chamber 3, the cooling chamber 3 is arranged on the support 1 and located One side of the heating chamber 2; a plurality of transmission rollers 4, a plurality of transmission rollers 4 are all rotatably mounted on the support 1, the heating chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com