Laser penetration fusion welding device assisted by cooperation of double magnetic fields and ultrasonic waves

An auxiliary laser and deep penetration welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy formation of cracks, solubility differences, inclusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

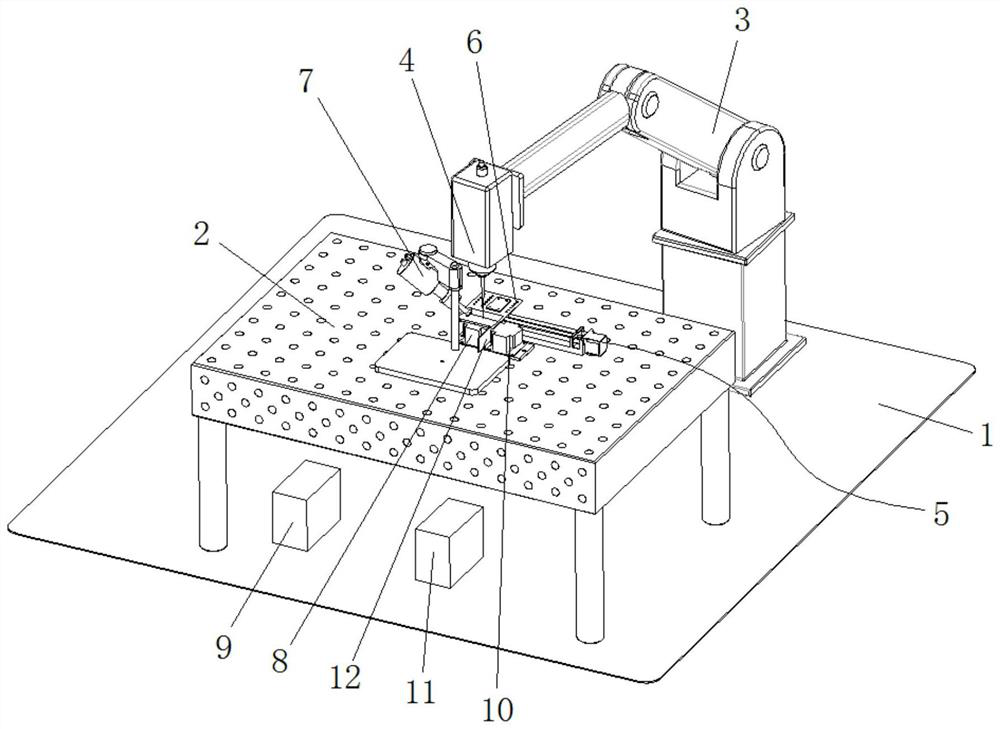

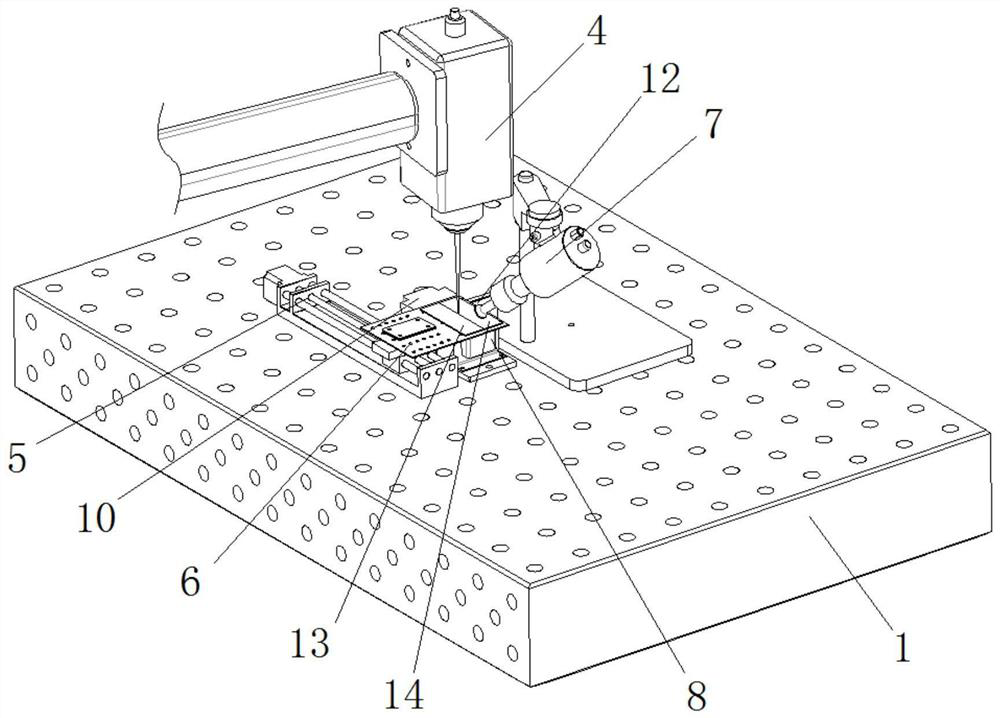

[0033] An embodiment of the present invention provides a laser deep penetration welding device assisted by dual magnetic fields and ultrasonic waves, such as Figure 1-2 As shown, it includes a base 1, a workbench 2, a mechanical arm 3, a laser welding machine 4, a moving mechanism 5, a welding table 6, an ultrasonic vibration machine 7, an alternating electromagnetic field coil 8, an alternating electromagnetic field power supply 9, and a constant electromagnetic field coil 10. The constant electromagnetic field power supply 11, the workbench 2 and the mechanical arm 3 are all arranged on the base 1, and the workbench 2 is hollowed out. The moving mechanism 5 is arranged on the workbench 2 and can drive the welding table 6 to move laterally, and the moving mechanism 5 is a screw slide mechanism. The welding table 6 is used to place the aluminum plate 13 and the magnesium plate 14, and the workbench 2 is provided with a clamping assembly for fixing the aluminum plate 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com