Cracking gas deoxidation catalyst as well as preparation method and application thereof

A gas deoxidation catalyst and gas cracking technology, applied in the field of olefin purification, can solve the problems of frequent regeneration of deoxidizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

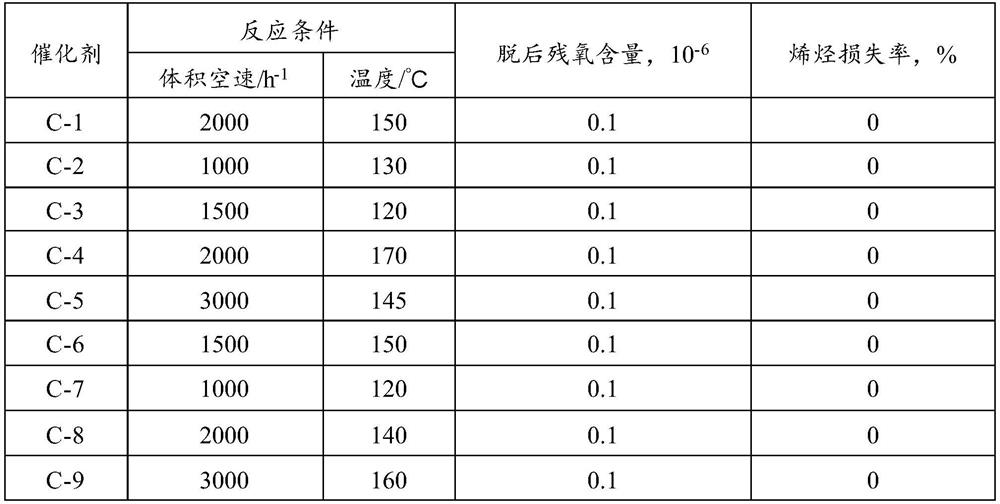

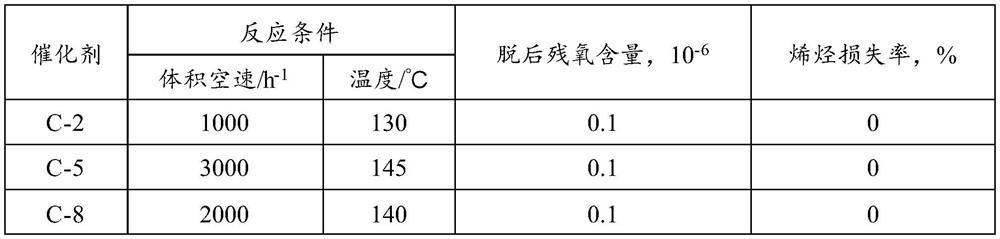

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the cracked gas deoxygenation catalyst described in the above technical solution, comprising the following steps:

[0035] a) mixing the precursor of metal MO, acid and water to obtain a metal salt solution;

[0036] b) Mn 3 o 4 The precursor and the binder are mixed evenly, and then the metal salt solution obtained in step a) is put in, and after molding, it is dried, dried and roasted in sequence to obtain a cracked gas deoxidation catalyst.

[0037] In the present invention, firstly, the metal MO precursor, acid and water are mixed to obtain a metal salt solution. In the present invention, the precursor of the metal MO is preferably any of the soluble nitrate, chloride, acetate, basic carbonate or oxalate of the metal MO, and the present invention relates to its type and source There are no special restrictions. It can be seen from the description that the metal MO is NiO and / or CuO, the precursor of the ...

Embodiment 1

[0059] Weigh 39.90g deionized water, dissolve 0.40g 65wt% concentrated nitric acid, 1.77g nickel nitrate, and 7.14g copper nitrate in deionized water, stir evenly, and the solution appears transparent; then weigh 76.12g manganese carbonate, 59.85g pseudo thin After diaspore, 6.65g of high alumina cement, and solid powder are mixed evenly, put the prepared impregnating solution into it, knead evenly, extrude into a 2mm cylindrical shape, dry at room temperature for 8 hours, dry at 120°C for 6 hours, and in air atmosphere at 500°C Calcined for 4h to obtain catalyst C-1.

Embodiment 2

[0061] Weigh 42.00g of deionized water, dissolve 0.42g of 65wt% concentrated nitric acid, 3.93g of nickel nitrate, and 11.91g of copper nitrate in deionized water, stir evenly, and the solution appears transparent; then weigh 68.50g of manganese carbonate, 63.00g of pseudo thin After diaspore, 7.00g of high alumina cement, and solid powder are mixed evenly, put the prepared impregnating solution into it, knead evenly, extrude into a 2mm cylindrical shape, dry at room temperature for 6 hours, dry at 110°C for 8 hours, and air at 450°C Calcined for 4h to obtain catalyst C-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com