Refinery dry gas acetylene removal catalyst as well as preparation method and application thereof

A technology for refinery dry gas and catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., and can solve the problems of high price, poor hydrogenation selectivity, and easy loss of catalyst active components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

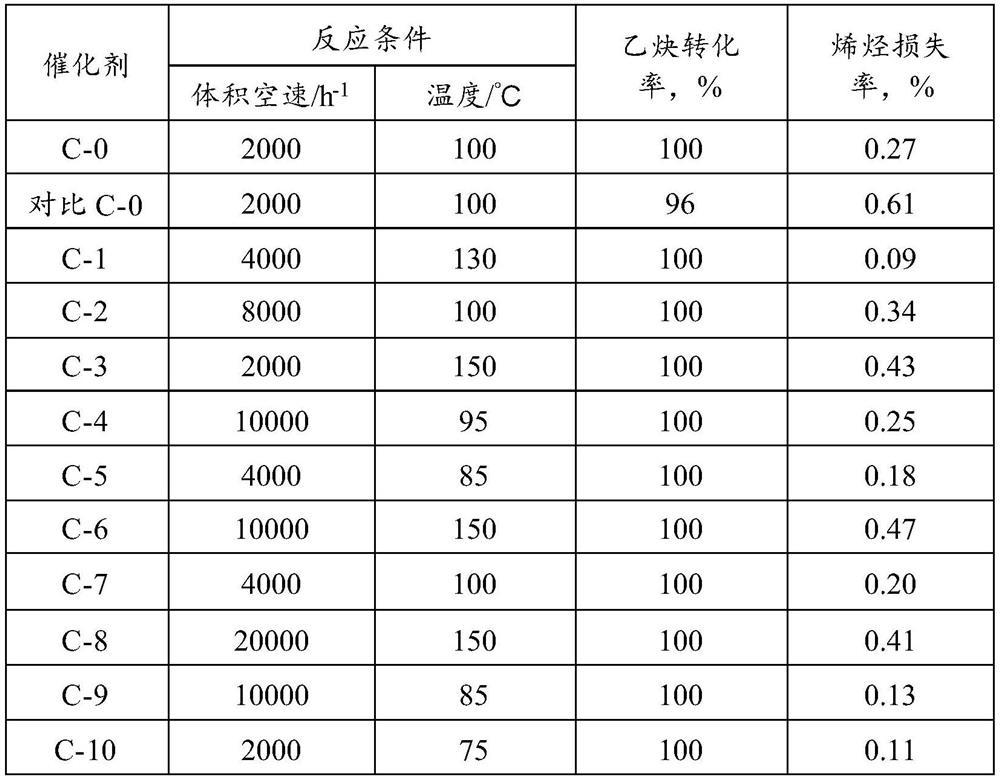

Examples

preparation example Construction

[0038] The present invention also provides a kind of preparation method of above-mentioned refinery dry gas deacetylation catalyst, comprises the following steps:

[0039] A) The aluminum precursor and the titanium precursor are mixed in a solvent according to the mass fraction ratio, and TiO is obtained after drying and roasting 2 Modified Al 2 o 3 ;

[0040] B) the TiO 2 Modified Al 2 o 3 Equal volume impregnation in impregnation solution, drying and roasting to obtain refinery dry gas deacetylation catalyst;

[0041] The immersion liquid includes Cu 2+ 、Ni 2+ and Ce 4+ .

[0042] In the invention, a titanium precursor and an aluminum precursor are used to prepare a carrier, and then the copper precursor, the nickel precursor and the cerium precursor are loaded on the carrier by an equal-volume impregnation method, and then the catalyst is obtained by roasting.

[0043] Specifically, the present invention prepares catalyst according to the following steps:

[0044...

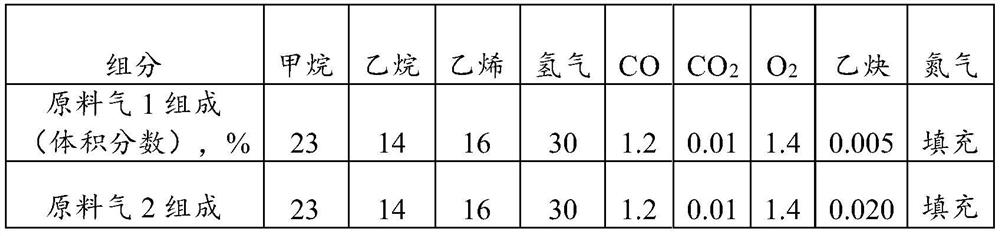

Embodiment 1

[0074] Weigh 200g of aluminum hydroxide dry glue, 40g of metatitanic acid, 7g of 65wt% concentrated nitric acid, and 140g of deionized water, mix them evenly, extrude into a cylindrical shape of 1-2mm, dry at 120°C for 4h, and roast at 600°C for 3h to obtain Carrier S-1. The water absorption of carrier S-1 was measured to be 55%.

[0075] Prepare 5.5ml of a mixed aqueous solution containing copper nitrate, nickel nitrate and cerium nitrate as the immersion solution, in the immersion solution, the amount of copper nitrate is 5% by weight in terms of copper element, and the amount of nickel nitrate is 1% by weight in terms of nickel element, and Nitric acid is 1% by weight based on cerium element. At room temperature, take 10 g of carrier S-1, impregnate with 5.5 mL of the previously prepared impregnating solution, dry at 110°C for 4 hours, then calcinate at 550°C for 4 hours, take it out and cool to room temperature, and obtain the catalyst C-0 .

Embodiment 2

[0076] Embodiment 2 prepares comparative catalyst

[0077] Carrier S-1 was prepared according to the method of Example 1.

[0078]Prepare 5.5 ml of a mixed aqueous solution containing copper nitrate, cobalt nitrate and cerium nitrate as the immersion solution, in the immersion solution, the amount of copper nitrate is 5% by weight in terms of copper element, and the amount of cobalt nitrate is 1% by weight in terms of cobalt element, and Nitric acid is 1% by weight based on cerium element. At room temperature, 10 g of carrier S-1 was taken, impregnated with 5.5 mL of the previously prepared impregnating solution, dried at 110°C for 4 hours, then calcined at 550°C for 4 hours, taken out and cooled to room temperature, and the catalyst obtained was Comparative C- 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com