Binder-free oxygen-defect-containing carbon-coated oxide electrode and battery

A binder-free, oxide-free technology, applied in battery electrodes, secondary batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

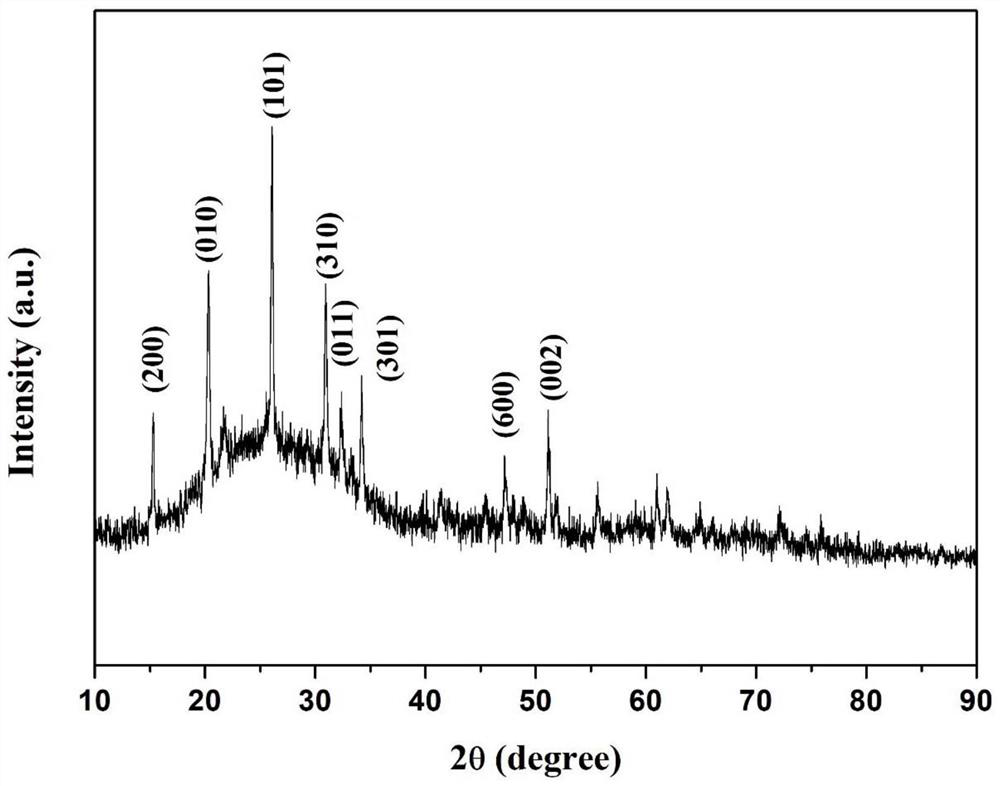

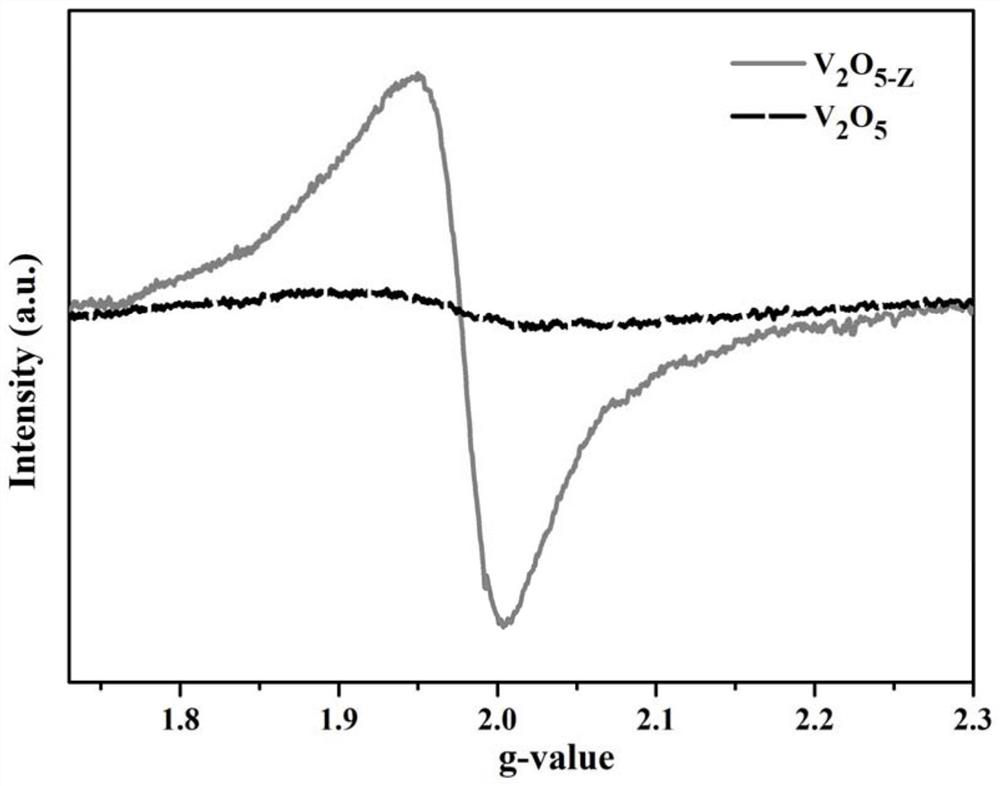

[0033] In this embodiment, a carbon-coated V containing oxygen defects 2 o 5-Z Electrode, the preparation method is as follows:

[0034] Ammonium metavanadate is selected as the reactant, and water is used as the solvent. Weigh 1g of ammonium metavanadate into a beaker, add 100mL of water, adjust the pH value of the mixed solution to 4 with hydrochloric acid, place the titanium foil in the mixed solution and transfer it to the reaction vessel, and keep it at 150°C for 6h. After natural cooling, the titanium foil was collected, washed repeatedly with deionized water, and dried in vacuum for 10 h. Finally, the titanium foil was calcined at 700 °C for 2 h in a 5% acetylene / argon atmosphere to obtain carbon-coated V with oxygen defects. 2 o 5-Z Material.

[0035] The electrode of this embodiment is made of titanium foil current collector and active material V 2 o 5-Z composition, the active material grows directly on the surface of the current collector, Figure 5 It can be...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is;

[0038] Select ferrous sulfate as reactant, water as solvent. Weigh 1.5g of ferrous sulfate into a beaker, add 150mL of water, adjust the pH value of the mixed solution to 5 with sulfuric acid, place the titanium foil in the mixed solution and transfer it to the reaction vessel, and keep it at 180°C for 10h. After natural cooling, the titanium foil was collected, washed repeatedly with deionized water, and dried in vacuum for 10 h. Finally, the titanium foil was calcined at 650 °C for 4 h in a 5% acetylene / argon atmosphere to obtain carbon-coated Fe with oxygen defects. 2 o 3-Z Material.

experiment example 3

[0040] The difference between this embodiment and embodiment 1 is;

[0041] Select tin chloride as the reactant and water as the solvent. Weigh 1.2g of tin chloride into a beaker, add 150mL of water, adjust the pH value of the mixed solution to 6 with acetic acid, place the titanium foil in the mixed solution and transfer it to a reaction vessel, and keep it at 200°C for 12h. After natural cooling, the titanium foil was collected, washed repeatedly with deionized water, and dried in vacuum for 10 hours. Finally, the titanium foil was calcined at 550 °C for 6 hours in a 5% acetylene / argon atmosphere to obtain carbon-coated SnO with oxygen defects. 2-Z Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com