Perovskite photoelectric assembly and packaging process thereof

A technology of optoelectronic components and packaging technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

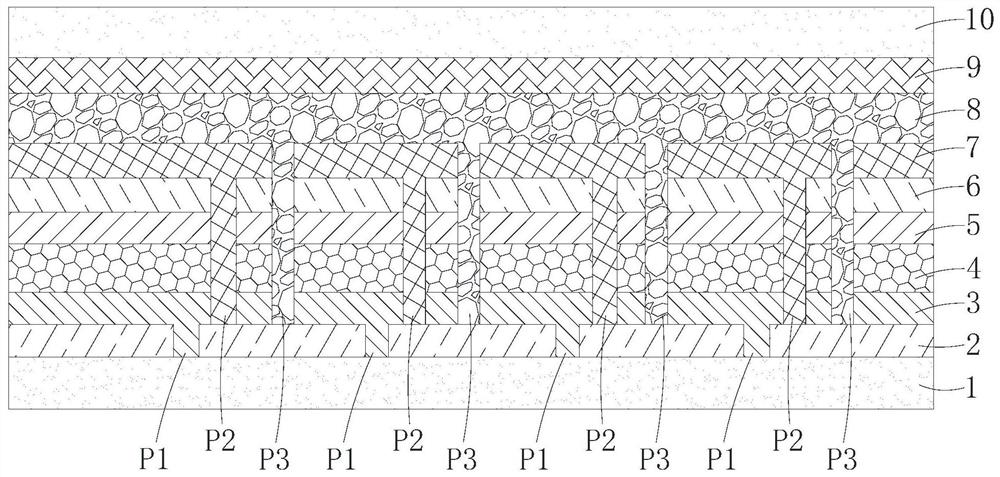

[0037] The first embodiment of the packaging process of the perovskite optoelectronic component of the present invention includes the following steps:

[0038] Step 11 , perform laser etching on the conductive glass substrate 1 on which the fluorine doped tin oxide (FTO) front conductive layer 2 is deposited, and etch away the FTO with a width of 50 μm, which is marked as a cutting line groove P1 . The conductive glass substrate 1 on which the conductive layer 2 before the FTO is deposited is cleaned, dried with nitrogen, and treated with ultraviolet and ozone.

[0039] Step 12, deposit TiO on the front conductive layer 2 2 The front carrier transport layer 3, the material of the front carrier transport layer 3 fills the cutting line groove P1, and the front carrier transport layer 3 includes a dense layer with a thickness of 20 nm and a mesoporous layer with a thickness of 100 nm. The substrate of the carrier transport layer 3 was heated to 70°C before deposition. The prepa...

Embodiment 2

[0047] The second embodiment of the packaging process of the perovskite optoelectronic component of the present invention includes the following steps:

[0048] Step 21 , perform laser etching on the conductive glass substrate 1 on which the indium doped tin oxide (ITO) front conductive layer 2 is deposited, and etch away the ITO with a width of 100 μm, which is denoted as a cutting line groove P1 . Then, the conductive glass substrate 1 on which the pre-ITO conductive layer 2 is deposited is cleaned, dried with nitrogen, and treated with ultraviolet and ozone.

[0049] Step 22 , spray a 20 nm NiOx front carrier transport layer 3 on the front conductive layer 2 , and the material of the front carrier transport layer 3 fills the cutting wire slot P1 . After drying, keep the temperature of substrate 1 at 70°C, spray 0.7mol / L lead iodide solution, and use N,N-dimethylformamide and dimethyl sulfoxide with a volume ratio of 9:1 as a mixed solvent, Annealed at 70 °C for 10 min to o...

Embodiment 3

[0057] The third embodiment of the packaging process of the perovskite optoelectronic component of the present invention includes the following steps:

[0058] Step 31 , perform laser etching on the conductive glass substrate 1 on which the indium doped tin oxide (ITO) front conductive layer 2 is deposited, and etch away the ITO with a width of 80 μm, which is marked as a cutting line groove P1 . Then, the conductive glass substrate 1 on which the pre-ITO conductive layer is deposited is cleaned, dried with nitrogen, and treated with ultraviolet and ozone.

[0059] Step 32: Coating poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine] (PTAA) with a thickness of 20 nm on the front conductive layer 2 as the front carrier transport layer 3, The material of the front carrier transport layer 3 fills the cutting wire slot P1. After drying, 1.2mol / L MAPbI 3 The methylamine acetic acid solution was coated on the surface of the front carrier transport layer 3 and annealed at 100° C. for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com