Method for manufacturing lower substrate of triple-medium layer of field emission display

A field emission and display technology, applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problems of poor insulation and short circuit of cathode grids, and achieve the effect of improving withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

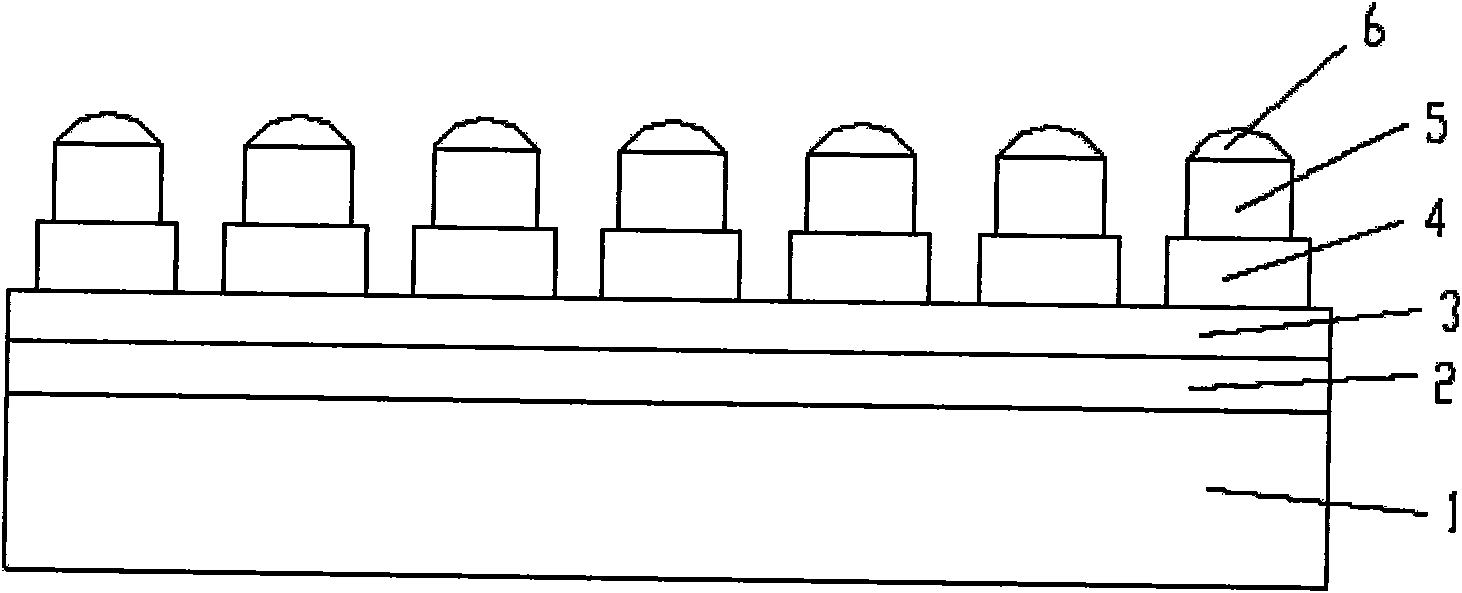

[0018] A method for manufacturing a substrate under a triple dielectric layer of a field emission display, comprising the steps of:

[0019] 1) On the glass substrate 1, use the electrode paste VG903 of DuPont to print the gate electrode layer 2 in sequence, and then use the prepared photosensitive medium paste to print the first photosensitive medium layer 3, and dry it at 100°C for 30 minutes to obtain the grid electrode. The thickness of the electrode layer 2 is 10 microns, and the thickness of the first photosensitive medium layer 3 is 30 microns;

[0020] 2) Cover the first photosensitive medium layer 3 and the gate electrode layer 2 with a grid mask plate, and perform one-time exposure and development on the first photosensitive medium layer 3 and the gate electrode layer 2. The exposure time is 12 minutes, and the wavelength of ultraviolet light is 360 nanometers, and then developed with 0.5% aqueous sodium carbonate solution to obtain grid line patterns;

[0021] 3) P...

Embodiment 2

[0028] A method for manufacturing a substrate under a triple dielectric layer of a field emission display, comprising the steps of:

[0029] 1) On the glass substrate 1, the electrode paste VG903 of DuPont Company was used to print the gate electrode layer 2 sequentially, and then the first photosensitive medium layer 3 was printed using the prepared photosensitive medium paste, and dried at 120° C. for 20 minutes to obtain the first The thickness of the photosensitive medium layer is 15 microns, and the thickness of the gate electrode layer 2 is 10 microns;

[0030] 2) Cover the first photosensitive medium layer 3 and the gate electrode layer 2 with a grid mask plate, and perform one-time exposure and development on the first photosensitive medium layer 3 and the gate electrode layer 2. The exposure time is 12 minutes, and the wavelength of ultraviolet light is 360 nanometers, and then developed with 0.5% aqueous sodium carbonate solution to obtain grid line patterns;

[003...

Embodiment 3

[0038] A method for manufacturing a substrate under a triple dielectric layer of a field emission display, comprising the steps of:

[0039] 1) On the glass substrate 1, use the electrode paste VG903 of DuPont to print the gate electrode layer 2 in sequence, and then use the prepared photosensitive medium paste to print the first photosensitive medium layer 3, and dry it at 130°C for 10 minutes to obtain the grid electrode. The thickness of the electrode layer 2 is 30 microns, and the thickness of the first photosensitive medium layer 3 is 20 microns;

[0040] 2) Cover the first photosensitive medium layer 3 and the gate electrode layer 2 with a grid mask plate, and perform one-time exposure and development on the first photosensitive medium layer 3 and the gate electrode layer 2. The exposure time is 12 minutes, and the wavelength of ultraviolet light is 360 nanometers, and then developed with 0.5% aqueous sodium carbonate solution to obtain grid line patterns;

[0041]3) Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com