Surface-mounted controlled fuse

A patch type, fuse technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of slow heat transfer efficiency, detachment of the heating sheet, affecting heat transfer efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Please refer to Figure 1 to Figure 7 , Embodiment 1 of the present invention is:

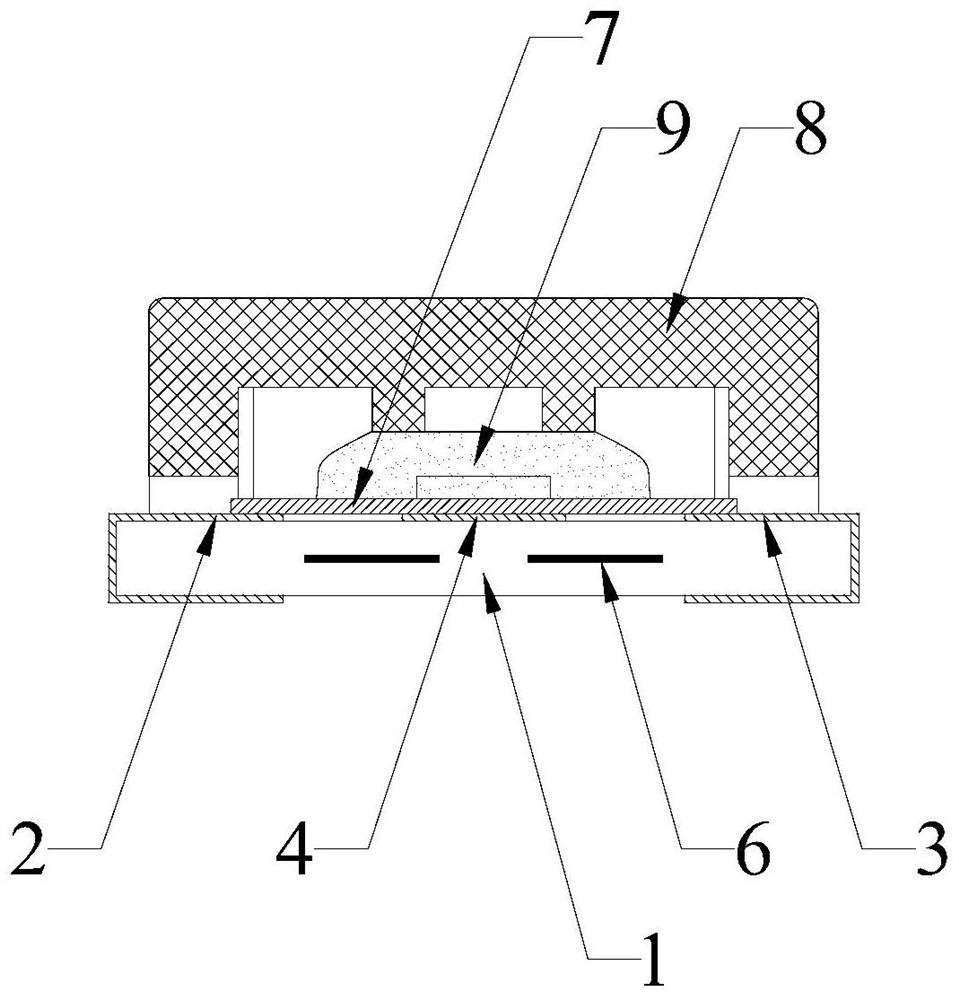

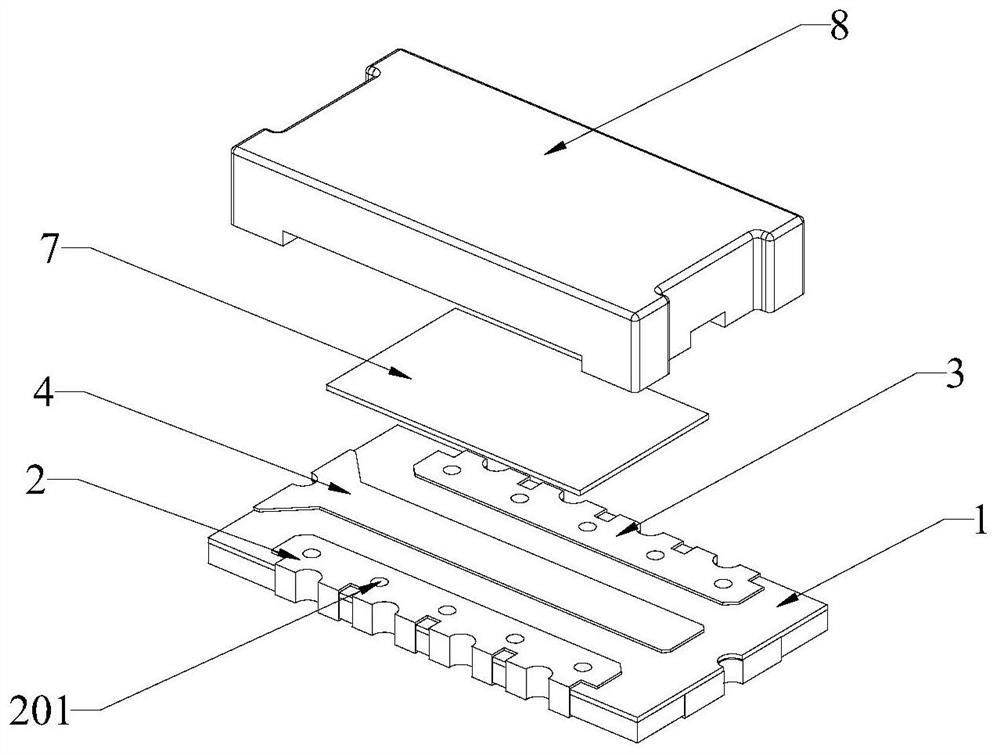

[0040] Please refer to figure 1 and image 3, a chip-type controlled fuse, including a first electrode 2, a second electrode 3 and a fusible alloy 7, the first electrode 2 is electrically connected to the second electrode 3 through the fusible alloy 7, and also includes a ceramic heating element Sheet 1, the ceramic heating sheet 1 is a heating element produced by printing resistance paste on an alumina ceramic green body and sintering at a high temperature, and the first electrode 2 and the second electrode 3 are respectively attached to the ceramic heating sheet 1 surface, the ceramic heating sheet 1 is provided with a heating electrode and the heating electrode is in contact with the fusible alloy 7.

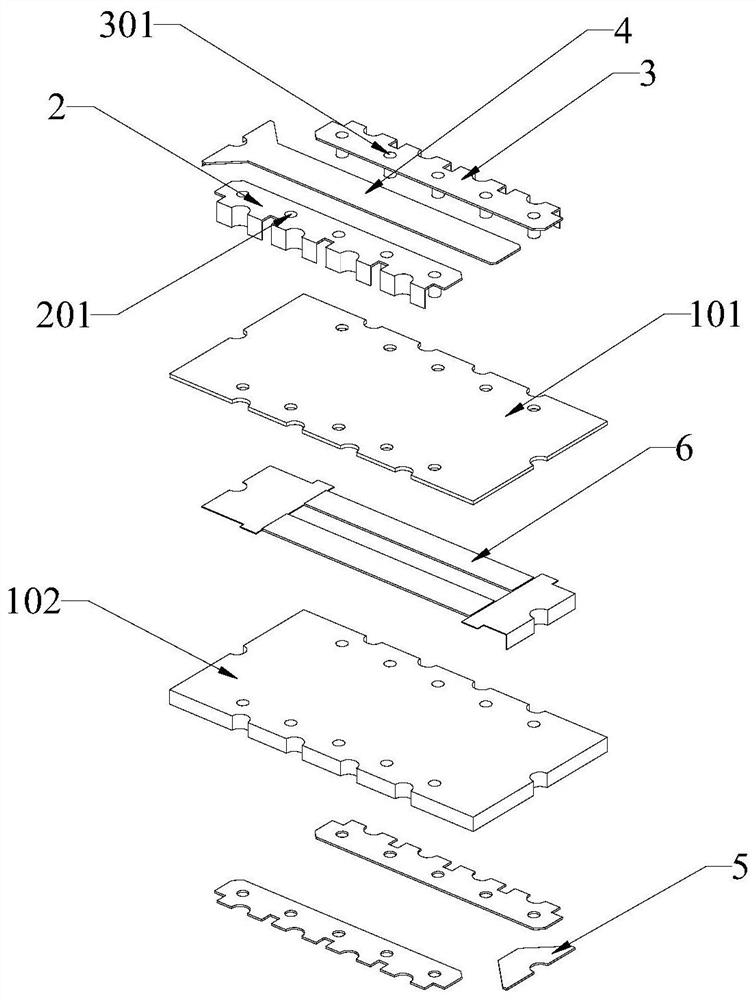

[0041] Please refer to figure 2 The ceramic heating sheet 1 includes an upper ceramic sheet 101 and a lower ceramic sheet 102, a heating resistor 6 is arranged between the upper ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com