Oiling agent for splitting waste polyester-cotton fabric and preparation method thereof

A technology of polyester-cotton fabric and oil agent, which is applied in the direction of plant fiber, fiber type, fiber treatment, etc., and can solve the problem of narrow application area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing an oil agent for fiber opening of waste polyester-cotton fabrics, comprising the steps of:

[0041] (1) 30g of oil phase and 10g of surfactant are sheared for 15min at room temperature and at a shear rate of 11350rpm, and mixed uniformly to obtain a coarse emulsion; wherein, the oil phase is dimethyl silicone oil, amino silicone oil, cyclic A mixture of oxygen-modified silicone oil and glycerin, the mass ratio is 3:4:1:4; the surfactant is polyoxyethylene lauryl ether, Tween 80, polydimethyldiallylammonium chloride Mixture, the mass ratio is 6:3:1;

[0042] (2) Add 45 g of water dropwise to the coarse emulsion in step (1) at a rate of 9 g / min, and shear and emulsify for 15 min at a shear rate of 11350 rpm to obtain a composite emulsion, namely an oil agent for fiber opening.

Embodiment 2

[0044] The oil phase in Example 1 was adjusted to 50g, 40g, and 20g; the others were kept the same as in Example 1 to obtain a composite emulsion, that is, an oil agent for fiber opening.

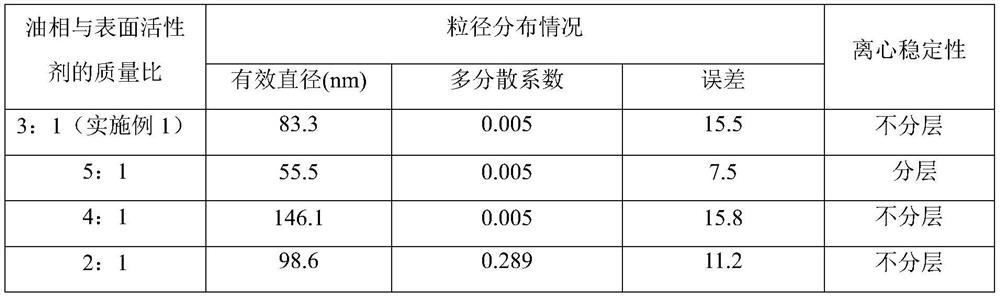

[0045] The mass ratio of the oil phase to the surfactant in Example 1 is 3:1 and the mass ratio of the oil phase to the surfactant in Example 2 is 5:1, 4:1, 2:1. Performance test, the test results are as follows:

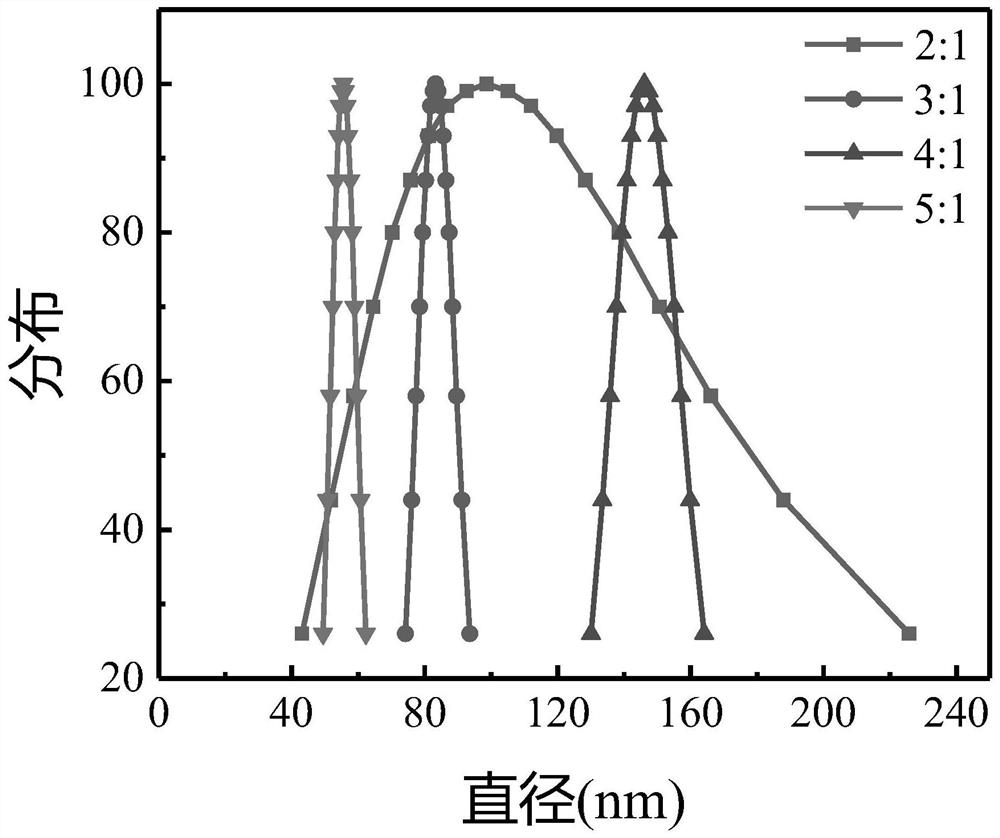

[0046] figure 1 The particle size distribution figure of the composite emulsion prepared for the oil phase and surfactant of different mass ratios in embodiments 1 and 2, from figure 1It can be clearly seen that the particle diameter of the oil agent is mainly distributed between 40 and 250nm. When the mass ratio of the oil phase to the surfactant is 2:1, the particle dispersibility is poor; the mass ratio of the oil phase to the surfactant is 3 :1, 4:1, 5:1, the dispersion is more concentrated and the uniformity is better.

[0047] Table 1 is the performance test result of th...

Embodiment 3

[0050] The selection of embodiment 3 oil phase

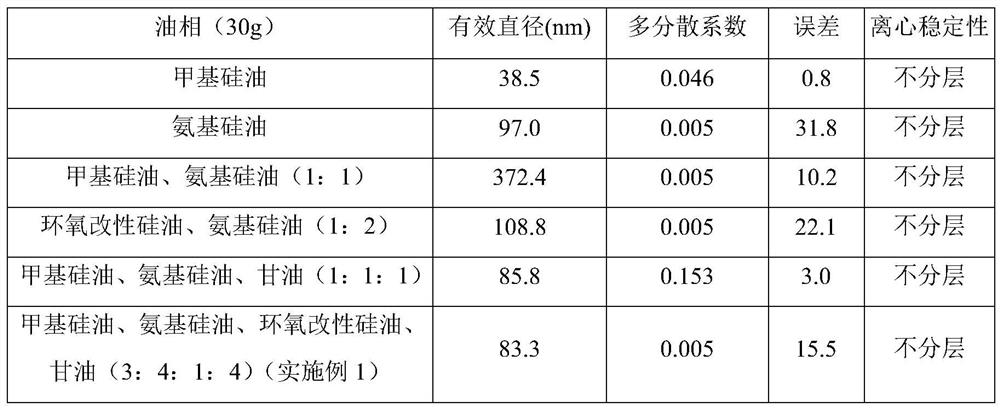

[0051] Adjust the oil phase in Example 1 to methyl silicone oil, amino silicone oil, the mass ratio of methyl silicone oil to amino silicone oil is 1:1, the mass ratio of epoxy-modified silicone oil to amino silicone oil is 1:2, methyl silicone oil, The mass ratio of amino silicone oil and glycerin is 1:1:1, the mass ratio of methyl silicone oil, amino silicone oil, epoxy-modified silicone oil, and glycerin is 3:4:1:4, and the others are consistent with Example 1 to obtain a composite Emulsion, that is, oil for fiber opening.

[0052] The fiber-opening oil agent that embodiment 3 is obtained is carried out performance test, and test result is as follows table 2:

[0053] It can be seen from Table 2: when using methyl silicone oil as the oil phase alone, the particle effective diameter is 38.5 ± 0.8nm, the particle size is low, the error is small but its dispersibility is poor; when amino silicone oil is used alone as the oil ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com