A kind of preparation method and device of oxidized pellet

A technology for oxidizing pellets and preparing devices, applied in the field of iron and steel metallurgy, can solve the problem of high equipment cost and achieve the effect of reducing equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

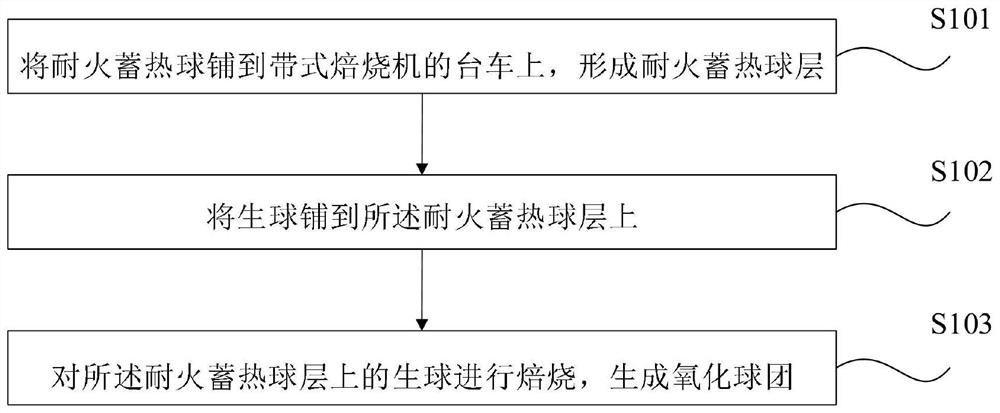

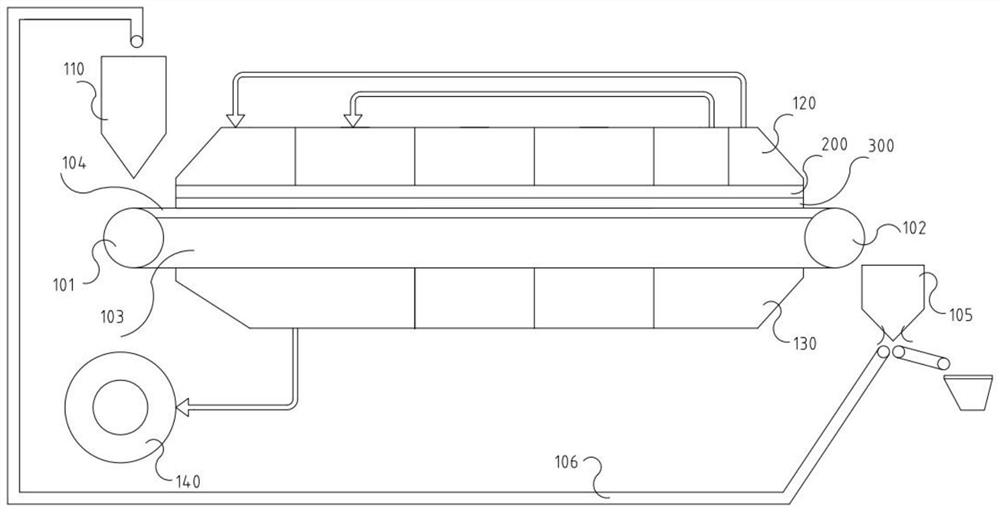

[0022] as Figure 1 As shown, embodiments of the present invention provides a method for preparing oxide pellets, comprising:

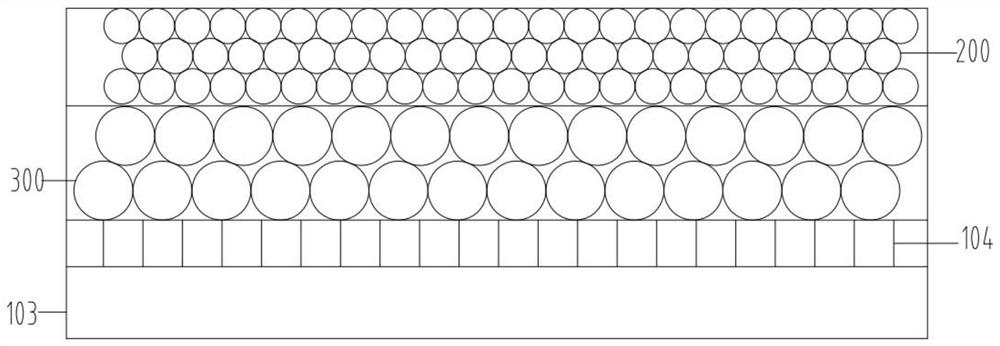

[0023] S101, the refractory regenerative ball is spread on the trolley with the belt roaster to form a refractory regenerative ball layer;

[0024] S102, the raw ball is laid on the refractory heat storage ball layer;

[0025] S103, the raw balls on the refractory heat storage sphere layer are roasted to form oxide pellets.

[0026] In the prior art, the oxide pellets as finished products are reused, and they are laid on the belt roaster as a base material and amyging material, which is used to protect the grate from high temperature damage, prevent powder clogging and bonding grates and other purposes. However, due to the limited ability of the oxide pellets to absorb heat, it is difficult to effectively reduce the temperature of the exhaust air after roasting, and the grates can still not be made of ordinary steel, and the strength of the oxide pellets w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com