LF (Ladle Furnace) and centring device and centring method for three-hole guide plate for electrodes of LF

A centering device and hole-guided technology, which is applied in the field of metallurgical equipment, can solve the problems of broken motors, increased construction costs and downtime, and the inability of electrodes to pass through three-hole plates accurately, so as to achieve fast and accurate centering and avoid production interruptions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, a ladle refining furnace (LF furnace) and a centering device for a three-hole guide plate thereof according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0024] figure 1 It is a schematic diagram of the position of the three-hole plate in the original normal state. When the electrode is inserted into the molten steel for heating, the molten steel violently boils and oxidizes in contact with the air, leaving some residue on the electrode rod. When the heating process is over, the electrode is lifted. In the process, the residue on the electrode rod will scrape and dislocate the three-hole plate, such as figure 2 shown.

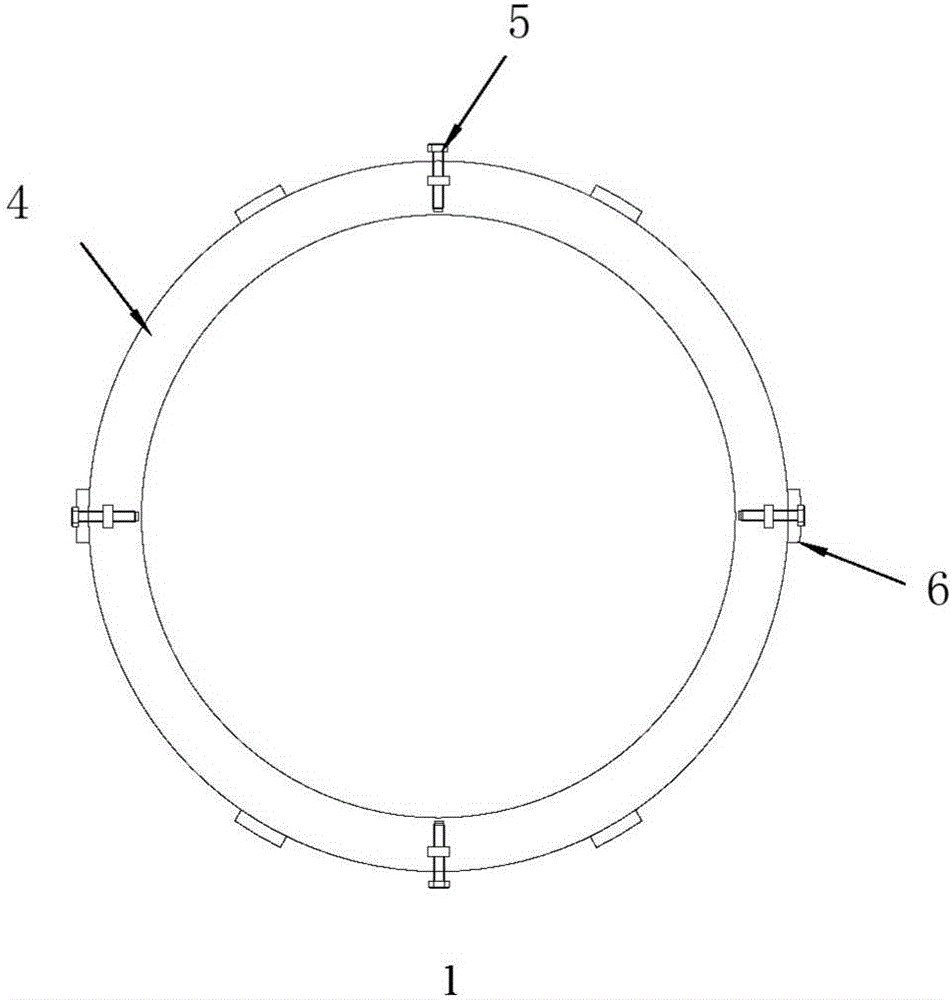

[0025] In an exemplary embodiment of the present invention, the centering device of the three-hole guide plate of the LF furnace electrode includes a supporting collar 4, a positioning piece 6, and at least three sets of centering components 5 fixed on the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com