A protection mechanism for process burners of entrained bed coal gasifiers

A process burner and protection mechanism technology, applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of cooling water coils affected by high temperature and weld cracks easily, so as to reduce material consumption, avoid contact with high temperature, good The effect of thermal protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to embodiments and drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

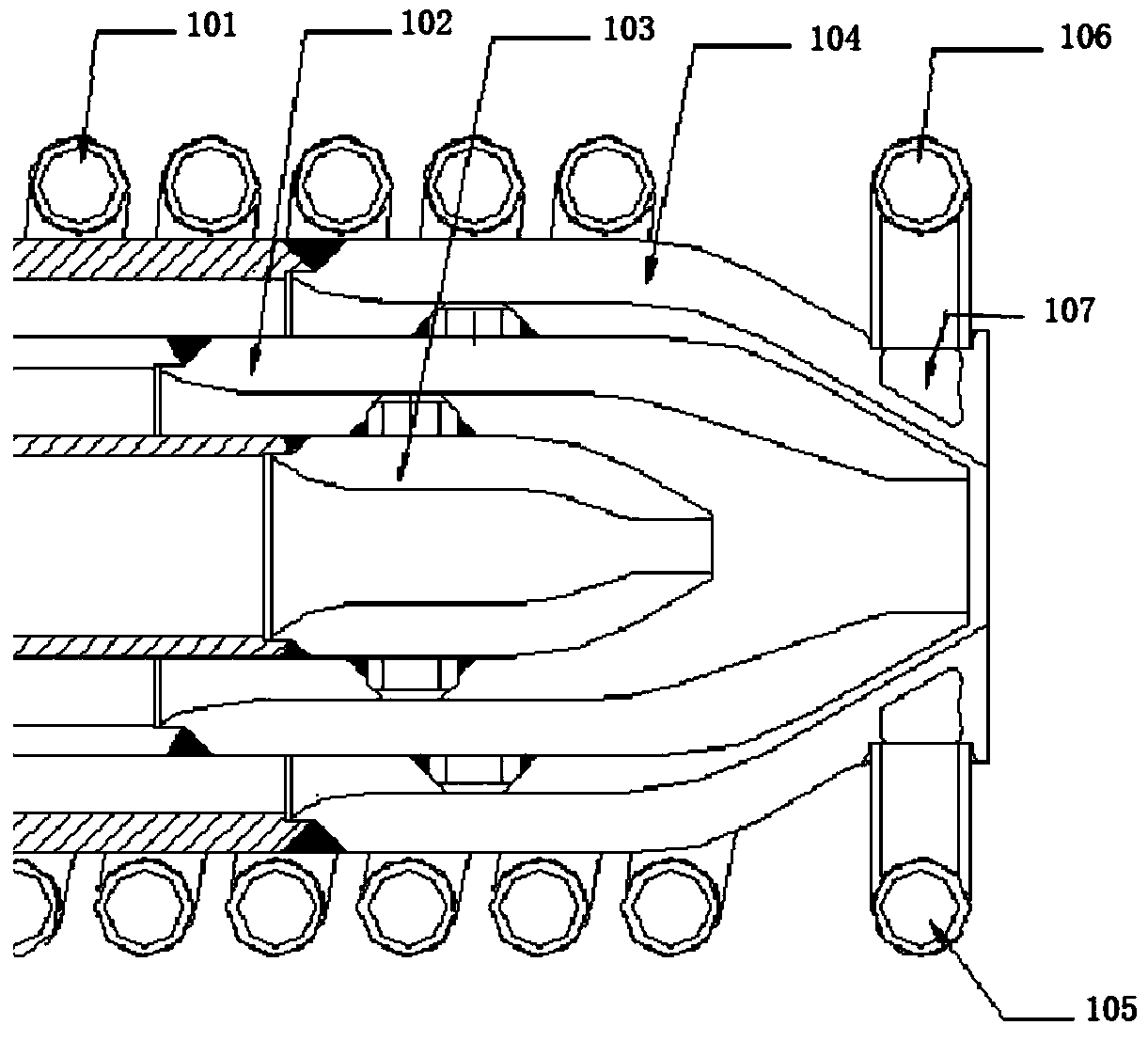

[0018] figure 1 Shows a cross-sectional view of an embodiment of the prior art process burner, its structure is concentric three sleeves, from the outside to the inside are the outer nozzle 104, the middle nozzle 102 and the inner nozzle 103, the outlet of the process burner nozzle It is designed into a necked form, which is beneficial to accelerate the gas ejected. The cooling water coil 101 surrounds and adheres to the outer side of the outer shell of the process burner nozzle 104, and shrinks with the process burner nozzle. The combustible atomized mixed gas is sprayed from the burner into the gasification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com