Film layer removal slurry, solar cell cutting method and semiconductor device scribing method

A technology of solar cell and cutting method, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of material residue and affecting cell efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

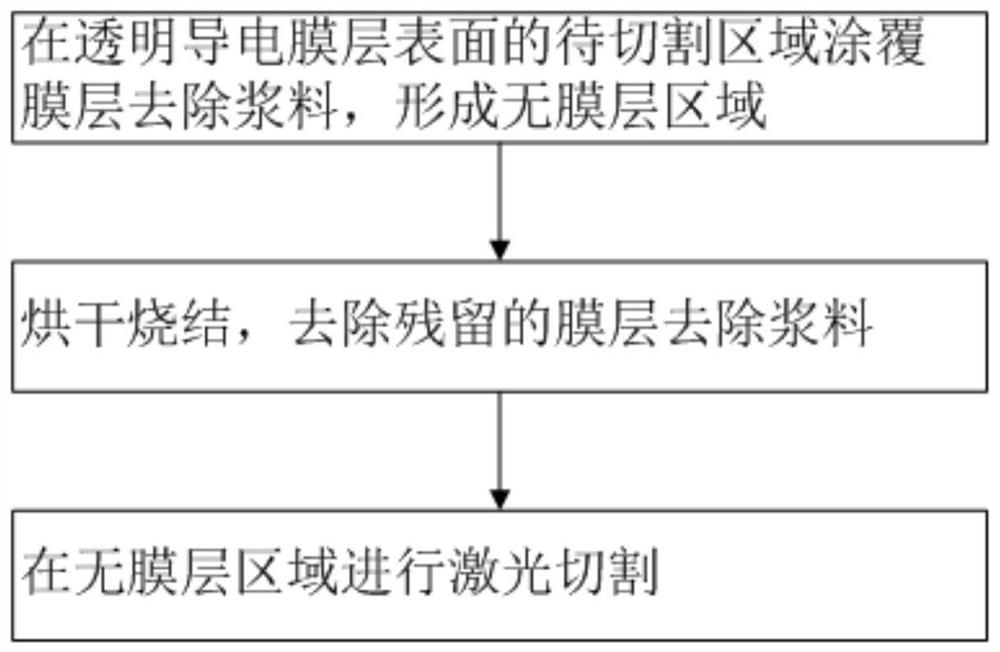

[0086] The present embodiment provides a cutting method of a solar battery sheet, comprising the following steps:

[0087] (1) Apply film layer removal slurry on the area to be cut on the surface of the transparent conductive film layer of the solar cell, and allow it to fully react for 1 min to form an ITO-free area.

[0088] In this step, it is preferable to coat the film layer removal slurry on the first transparent conductive film layer. Wherein, the composition of the film layer removal slurry includes the following components in volume percentage, phosphoric acid 5%; hydrofluoric acid 25%; terpineol 55%; polyamide wax 5%; polystyrene 10%. Screen printing technology was used to coat the film layer to remove the slurry, the coating thickness was 10 μm, and the coating width was 600 μm.

[0089] (2) drying and sintering to remove the residual film layer and remove the slurry.

[0090] Wherein, the temperature of drying and sintering is 170° C., and the time is 6 minutes. ...

Embodiment 2

[0094] The present embodiment provides a cutting method of a solar battery sheet, comprising the following steps:

[0095] (1) Apply film layer removal slurry on the area to be cut on the surface of the transparent conductive film layer of the solar cell, and allow it to fully react for 1 min to form an ITO-free area.

[0096] In this step, it is preferable to coat the film layer removal slurry on the first transparent conductive film layer. Wherein, the composition of the membrane layer removal slurry includes the following components in volume percentage: 5% phosphoric acid; 25% hydrofluoric acid; 45% terpineol; 10% polyamide wax; 15% polystyrene. Screen printing technology was used to coat the film layer to remove the slurry, the coating thickness was 15 μm, and the coating width was 800 μm.

[0097] (2) drying and sintering to remove the residual film layer and remove the slurry.

[0098] Wherein, the temperature of drying and sintering is 190° C., and the time is 6 minu...

Embodiment 3

[0102] The present embodiment provides a cutting method of a solar battery sheet, comprising the following steps:

[0103] (1) Apply film layer removal slurry on the area to be cut on the surface of the transparent conductive film layer of the solar cell, and allow it to fully react for 1 min to form an ITO-free area.

[0104] In this step, it is preferable to coat the film layer removal slurry on the first transparent conductive film layer. Wherein, the composition of the film layer removal slurry includes the following components in volume percentage, phosphoric acid 5%; hydrofluoric acid 25%; terpineol 50%; polyamide wax 7%; polystyrene 13%. Screen printing technology was used to coat the film layer to remove the slurry, the coating thickness was 12 μm, and the coating width was 1000 μm.

[0105] (2) drying and sintering to remove the residual film layer and remove the slurry.

[0106] Wherein, the temperature of drying and sintering is 180° C., and the time is 6 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com