Formaldehyde-removing coating containing negative ion powder and preparation method of formaldehyde-removing coating

A technology of negative ion powder and paint, applied in the field of paint, can solve problems such as poor flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is a flame retardant, and the preparation process of the flame retardant is as follows:

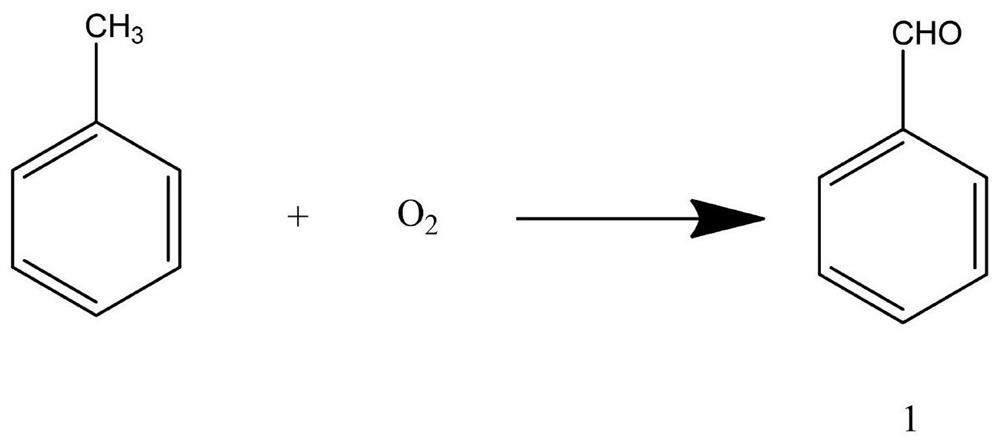

[0046] A1: Add the catalyst and half of glacial acetic acid into a three-necked flask equipped with an air duct and a stirrer, stir at a stirring rate of 150r / min until the catalyst is completely dissolved, then add toluene and continue stirring for 20min, then add the remaining Glacial acetic acid, heated to 95°C, fed with oxygen, heated to reflux for 10 hours, after the reaction, the reaction product was extracted twice with cyclohexane, the extracts were combined, and the cyclohexane was distilled off under reduced pressure to obtain intermediate 1; The control catalyst is cobalt acetate, manganese sulfate, manganese acetate and tetrabromoethane according to the molar ratio of 6:1:1:0.36, the molar ratio of cobalt acetate to toluene is 1:30, and the volume ratio of toluene to glacial acetic acid is 1: 1. The oxygen flow rate is 60mL / min;

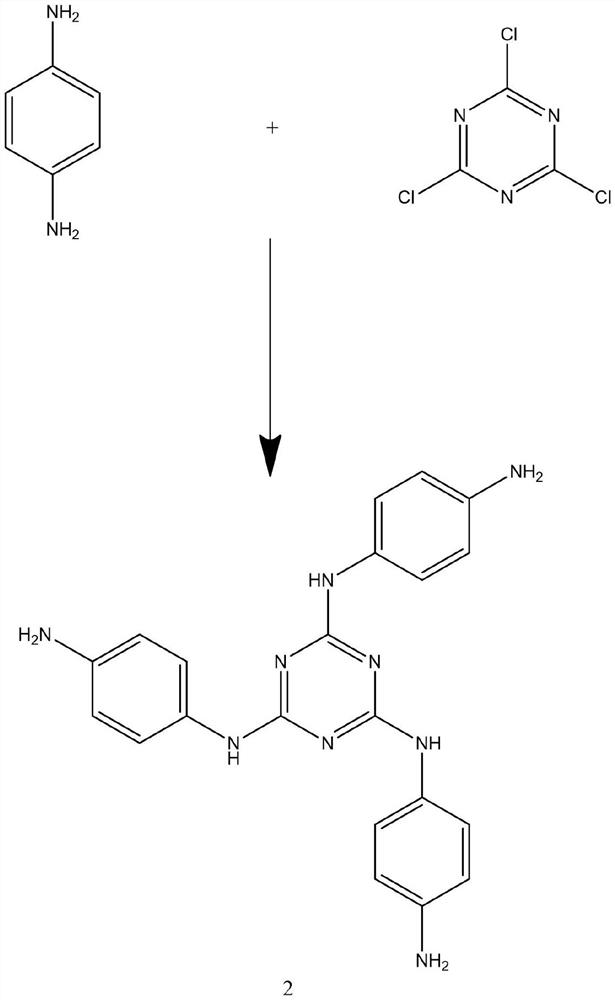

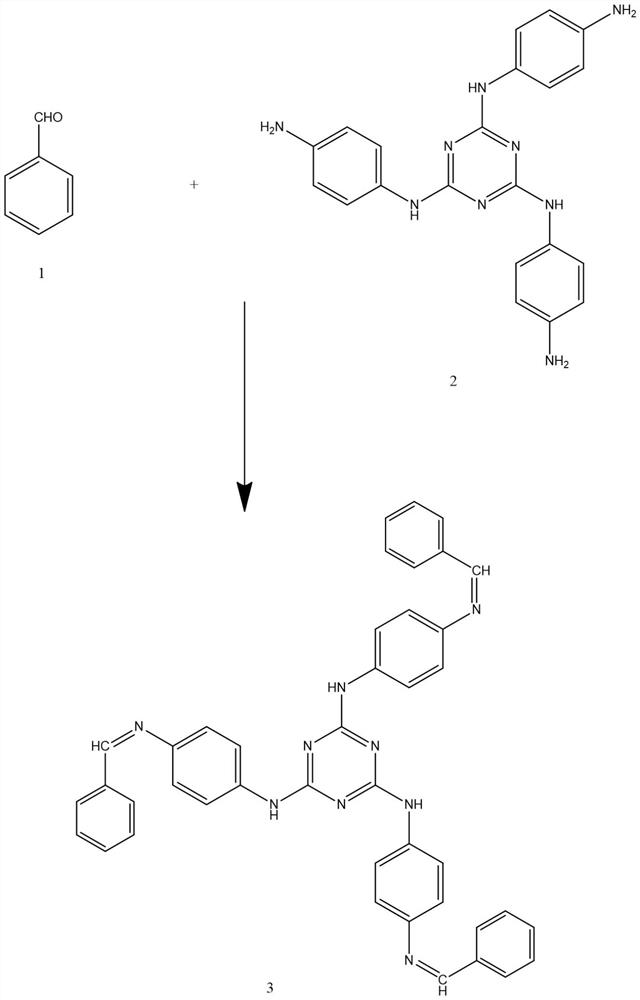

[0047] A2: Add p-pheny...

Embodiment 2

[0051] This embodiment is a flame retardant, and the preparation process of the flame retardant is as follows:

[0052] A1: Add the catalyst and half of glacial acetic acid into a three-necked flask equipped with an air duct and a stirrer, stir at a stirring rate of 300r / min until the catalyst is completely dissolved, then add toluene and continue stirring for 30min, then add the remaining Glacial acetic acid, under the condition of raising the temperature to 100°C, feed oxygen, heat and reflux for 12 hours, after the reaction, extract the reaction product with cyclohexane for 3 times, combine the extracts, and distill under reduced pressure to remove the cyclohexane to obtain intermediate 1; The control catalyst is cobalt acetate, manganese sulfate, manganese acetate and tetrabromoethane according to the molar ratio of 6:1:1:0.36, the molar ratio of cobalt acetate to toluene is 1:35, and the volume ratio of toluene to glacial acetic acid is 1: 1. The oxygen flow rate is 60mL / ...

Embodiment 3

[0057] This embodiment is a kind of aldehyde-removing powder, and the preparation process of aldehyde-removing powder is as follows:

[0058] B1: Add halloysite to the urea solution, sonicate for 1 h at an ultrasonic frequency of 45 kHz, then centrifuge and remove the supernatant, wash the precipitate twice with isopropanol, and then vacuum filter it. The filter cake is placed in a vacuum drying oven, dried to constant weight at a temperature of 70°C, and then ground into powder and passed through a 300-mesh sieve to obtain the carrier halloysite; the dosage ratio of halloysite and urea solution is controlled to be 2g : 50mL, the molar concentration of urea solution is 1mol / mL;

[0059] B2: Add the carrier halloysite into the reaction eggplant bottle, and treat it under negative pressure for 30 minutes under the condition of vacuum degree of -0.1MPa, then inject the 2-imidazolidinone aqueous solution into the reaction eggplant bottle through a syringe, shake for 30 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com