Water-resistant and fracture-resistant waterproof roll and preparation method thereof

A waterproof membrane and anti-fracture technology, which is applied to building insulation materials, roofs using flexible materials, building components, etc., can solve the problems of poor fracture resistance of waterproof membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

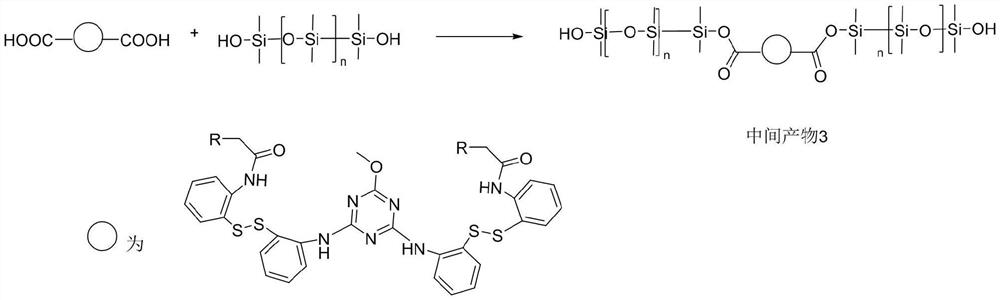

[0030] Elastic aid was made by:

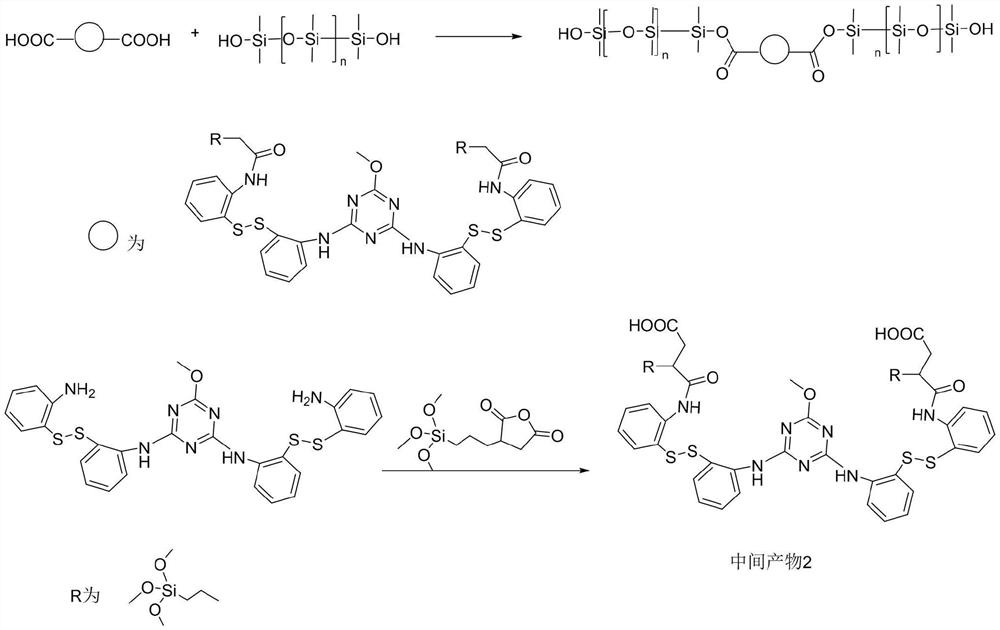

[0031] Step A, 2,4-dichloro-6-methoxy-1,3,5-triazine and toluene were added three-necked flask equipped with a stirrer, stirred at room temperature to 2,4-dichloro-6- -1,3,5-triazine was completely dissolved, and then placed in an ice-water bath system, bis (o) phenyl disulfide, stir, and the mass fraction of 10% sodium carbonate solution to adjust the system between pH 5-6, the reaction system was heated to 46 ℃, and stirring was continued 7H reaction, the reaction was stopped until the reaction was cooled to room temperature, filtered, and the filter cake was washed with deionized taken three times with water, and dried in vacuo at 40 ℃ tank dried to constant weight to give an intermediate product;

[0032] Procedure B, the intermediate product obtained in Step A 1 and a half of N, N- dimethylformamide was added three-necked flask equipped with a stirrer, and stirred to complete dissolution of Intermediate 1, then [3- (trimethoxy silyl) propyl] ...

Embodiment 2

[0038] Elastic aid was made by: with reference to the steps in Example 1.

[0039] The amount of the material in each step such as shown in Table 2.

[0040] Table 2

[0041]

[0042]

Embodiment 3

[0044] One kind of water fracture waterproofing membrane, comprising the following component parts by weight: 50 parts bitumen, 5 parts of a plasticizer, an elastic aid prepared in Example 1 2.5 parts, 12 parts of a flame retardant, an ultraviolet absorber 1.5, 2.5 parts antioxidant, 0.5 parts of a softening agent, wherein the plasticizer is the DOP; 3 ratio of the flame retardant is an organic flame retardant and an inorganic flame retardant in accordance with the quality: 1 were mixed mixture; said UV absorption agent is UV-329; the antioxidant is antioxidant 1010 and 168 antioxidant at a mass ratio of 1: 2 were mixed mixture; the softening agent is an aromatic oil.

[0045] This kind of water-fracture-resistant waterproof membrane is made of the steps of:

[0046]Softener while mixing with the bitumen and heated to 55 ℃, stirred for 20min; a plasticizer, an elastic aids, flame retardants, ultraviolet absorbers and antioxidants, heated to 75 ℃, stirred for 30min, and was at 135 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com