Preparation method and application of ultra-high purity scandium oxide

A scanning scandium oxide, ultra-high technology, applied in the field of metallurgy, can solve the problems of inability to deeply remove actinides, lanthanide rare earth elements, complicated preparation process operations, and low purity of scandium oxide, so as to reduce equipment investment costs, energy consumption, and operation The effect of simple process and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

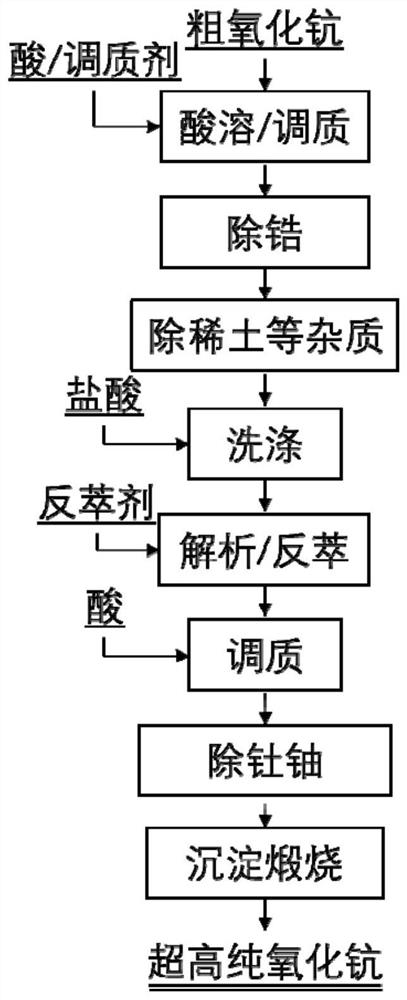

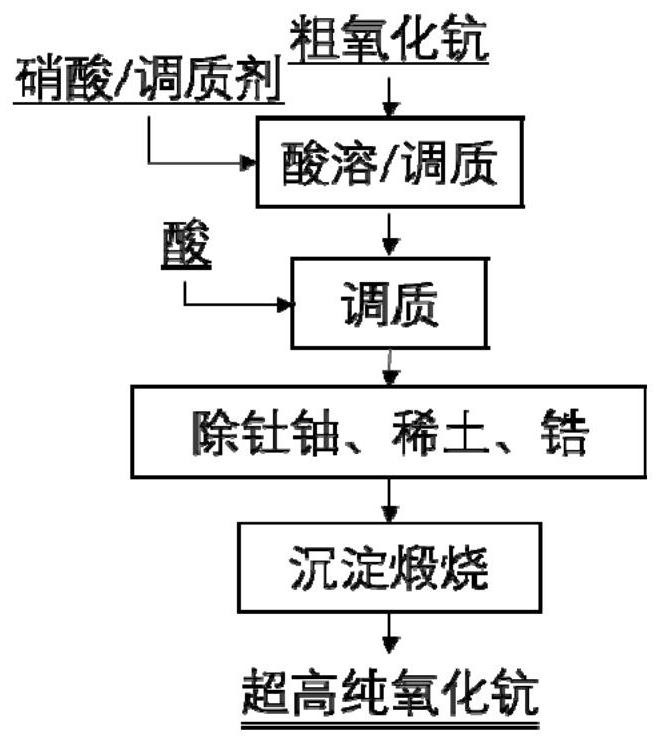

[0025] figure 1 A flow chart of a method for preparing ultra-high-purity scandium oxide in an optional embodiment of the present invention is schematically shown. like figure 1 As shown, a method for preparing ultra-high-purity scandium oxide provided by the present invention may include: acid-dissolving / tempering crude scandium oxide with acid / tempering agent, removing uranium (iron), removing zirconium, removing rare earth and other impurities, washed with hydrochloric acid, decomposed / back-extracted with a stripping agent, quenched and tempered with acid, removed thorium uranium and rare earth impurities, etc., precipitated and calcined, and obtained ultra-high-purity scandium oxide.

[0026] This embodiment of the present invention mainly realizes the ultra-high purification preparation of scandium in the hydrochloric acid system. This method can not only deeply remove actinide elements uranium and thorium, lanthanide rare earth elements, titanium and zirconium, etc., but...

Embodiment 1

[0063] The whole process of this example is carried out in a class 10,000 clean laboratory. The main components of the crude scandium oxide in this example are shown in Table 1 below.

[0064] The main impurities of table 1 crude scandium oxide (g / t)

[0065] Sc2O3 99.01% Sc2O3 / REO 99.97% La2O3 22.8 Al2O3 15.3 CeO2 28.2 ZrO2 15.8 Nd2O3 22.5 ThO2 307 Y2O3 60.8 U2O3 5 Er2O3 52.1 CuO 8.2 Rare earth impurities 259.2 V2O5 9.1 Fe2O3 61.2 Na2O 170 CaO 50 NiO 6.9 SiO2 38 TiO2 9.2

[0066] First, use hydrochloric acid to dissolve the crude scandium oxide sample; adjust the acidity to 9M; the filtrate is first finely filtered and then filtered through a N235 resin column to remove iron and uranium; Then extract with TBP (solvent), the extraction conditions are TBP 100%, O / A 1:1, and the extraction reaction time is 5 minutes; then the loaded organic phase is washed with 8M hydrochloric aci...

Embodiment 2

[0074] The whole process of this example is carried out in a class 10,000 clean laboratory. The main components of the crude scandium oxide in this example are also shown in Table 1.

[0075] First, use hydrochloric acid to dissolve the crude scandium oxide sample; adjust the acidity to 8M; filter the filtrate first, then filter the iron and uranium through N235 resin column; Extraction with TBP (solvent), extraction conditions TBP 50%, O / A 2:1, extraction reaction time 5min, cross-flow extraction 2-stage; then use 8M hydrochloric acid to wash the loaded organic phase, wash conditions O / A 2:1, wash Time 5min; use 3M HCl for back extraction, the ratio of back extraction is O / A 2:1, time 5min, cross-flow washing 2 levels; add a small amount of nitric acid to control the effective ion concentration of nitrate should be ≥ 0.05mol / L, quenched and tempered Then pass the filtrate through PMBP resin; after the filtrate is concentrated, oxalic acid is used for precipitation, and calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com