Preparation method and application of ultra-pure scandium oxide

A scanning scandium oxide, ultra-high technology, applied in the field of metallurgy, can solve the problems of scandium oxide low purity, high cost, and complicated preparation process operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

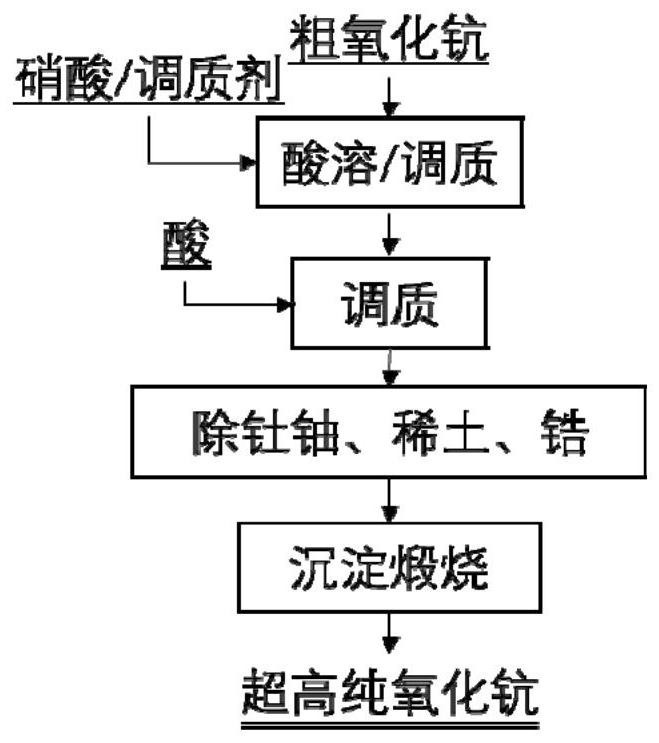

[0025] figure 1 It schematically shows the process flow of the method for preparing ultra-high-purity scandium oxide in an alternative embodiment of the present invention. Such as figure 1 As shown, the preparation method of a kind of ultra-high-purity scandium oxide provided by the present invention can comprise: to coarse scandium oxide, adopt acid / conditioning agent to carry out acid dissolution / conditioning, remove uranium (iron), remove zirconium, remove rare earth and other impurities, washed with hydrochloric acid, analyzed / retracted with stripping agent, tempered with acid to remove thorium, uranium and rare earth impurities, etc., precipitated and calcined to obtain ultra-high-purity scandium oxide.

[0026] This embodiment of the present invention mainly realizes the ultra-high purification preparation of scandium under the hydrochloric acid system. This method can not only deeply remove actinide elements uranium and thorium, lanthanide rare earth elements, titanium...

Embodiment 1

[0063] The entire process of this embodiment is carried out in a 10,000-class clean laboratory. The main components of crude scandium oxide in this example are shown in Table 1 below.

[0064] Table 1 Main impurities of crude scandium oxide (g / t)

[0065] Sc2O3 99.01% Sc2O3 / REO 99.97% La2O3 22.8 Al2O3 15.3 CeO2 28.2 ZrO2 15.8 Nd2O3 22.5 ThO2 307 Y2O3 60.8 U2O3 5 Er2O3 52.1 CuO 8.2 Rare earth impurities 259.2 V2O5 9.1 Fe2O3 61.2 Na2O 170 CaO 50 NiO 6.9 SiO2 38 TiO2 9.2

[0066] First, use hydrochloric acid to dissolve the crude scandium oxide sample; adjust the acidity to 9M; filter the filtrate first through a N235 resin column to remove iron and uranium; then pass through TBP resin to remove trace zirconium (the amount of resin is too high, resulting in a decrease in the direct yield of scandium); Then extract with TBP (solvent), extraction condition TBP 100%, O / A 1:1, extracti...

Embodiment 2

[0074] The entire process of this embodiment is carried out in a 10,000-class clean laboratory. The main components of crude scandium oxide in this example are also shown in Table 1.

[0075] First, use hydrochloric acid to dissolve the crude scandium oxide sample; adjust the acidity to 8M; filter the filtrate through an N235 resin column to filter out iron and uranium; then pass TBP resin to remove trace zirconium (the amount of resin is too high to cause the direct recovery of scandium to decline); Extract with TBP (solvent), extraction conditions TBP 50%, O / A 2:1, extraction reaction time 5min, cross-flow extraction 2 stages; then use 8M hydrochloric acid to wash the loaded organic phase, washing conditions O / A 2:1, wash Time 5min; back extraction with 3M HCl for back extraction, back extraction ratio O / A 2:1, time 5min, cross-flow washing 2 levels; add a small amount of nitric acid to control the effective ion concentration of nitrate should be ≥ 0.05mol / L, conditioning T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com