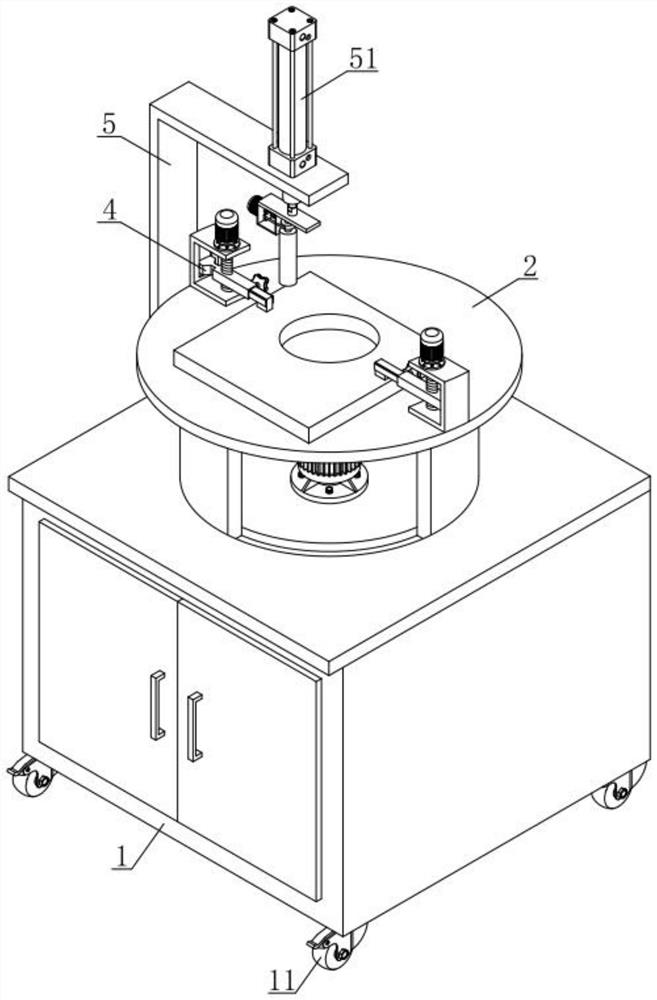

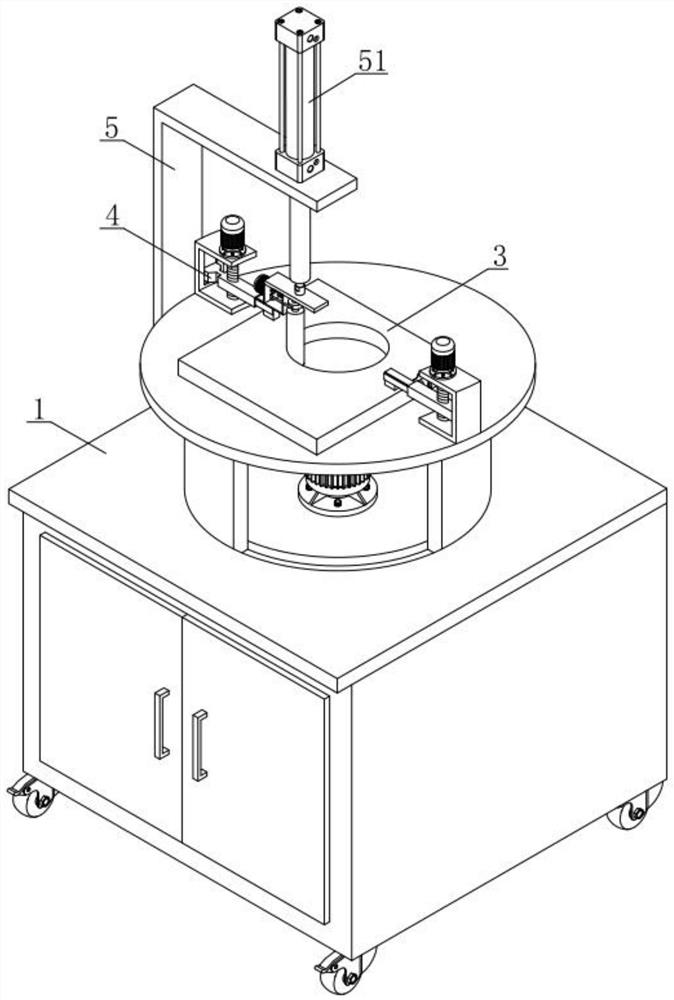

Aluminum alloy support inner hole high-precision grinding device and implementation method thereof

An aluminum alloy bracket and inner hole technology, which is applied in the field of aluminum alloy brackets, can solve the problems that the aluminum alloy bracket cannot be fixed, the inner hole of the aluminum alloy bracket cannot be polished, and the scope of application is narrow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

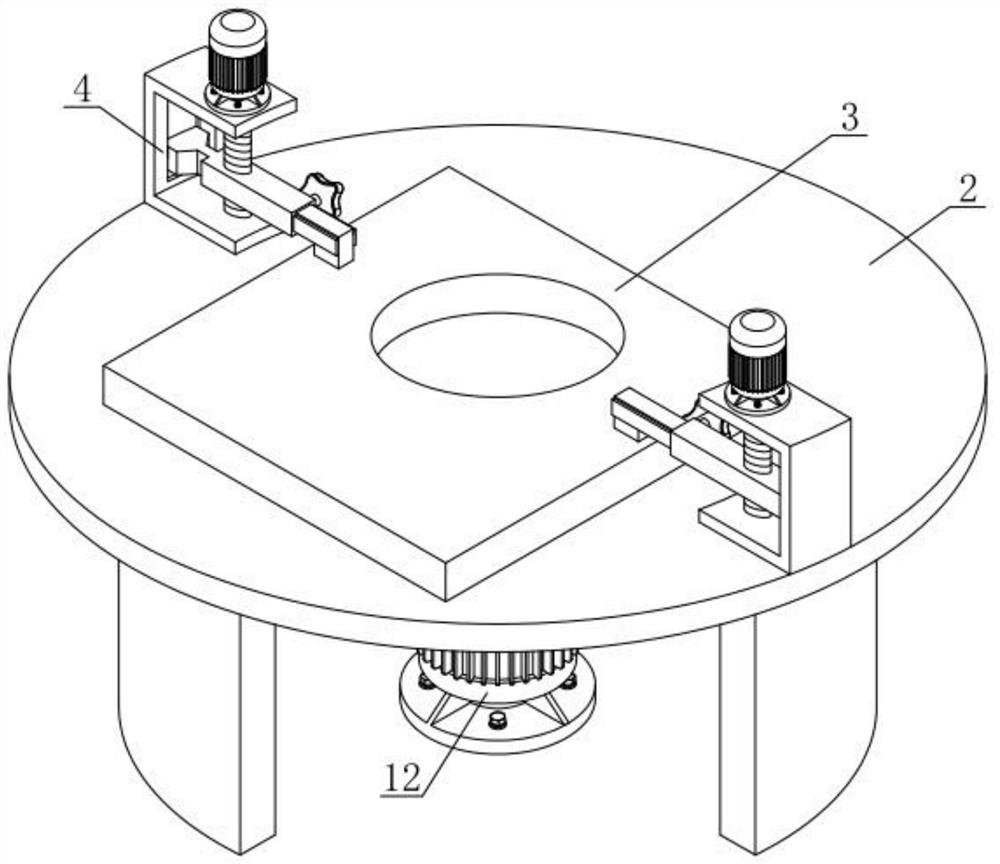

[0044] In order to better demonstrate the implementation process of the high-precision grinding device for the inner hole of the aluminum alloy bracket, this embodiment now proposes a method for implementing the high-precision grinding device for the inner hole of the aluminum alloy bracket, including the following steps:

[0045] S1: Place the aluminum alloy bracket 3 to be processed on the rotating disk 2, and make the inner hole of the aluminum alloy bracket 3 to be processed be located at the middle end of the rotating disk 2;

[0046] S2: adjust the length of the inner pressure plate 442 protruding from the outer sliding seat 441 through the torx bolt 443, so that the inner pressure plate 442 can be pressed on the aluminum alloy bracket 3 to be processed;

[0047] S3: The drive motor 42 drives the transmission screw 43 to rotate to make the clamping part 44 move down under the guidance of the guide slider 45, so that the inner pressure plate 442 is pressed on the aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com