Preparation method and application of iron pillared montmorillonite composite catalyst

A composite catalyst, iron proppant technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of surface acid site reduction, nitrophenol wastewater pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

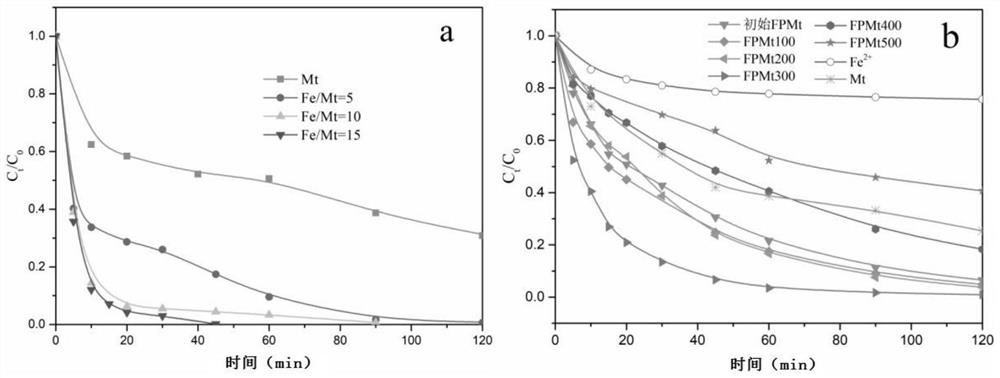

Embodiment 1

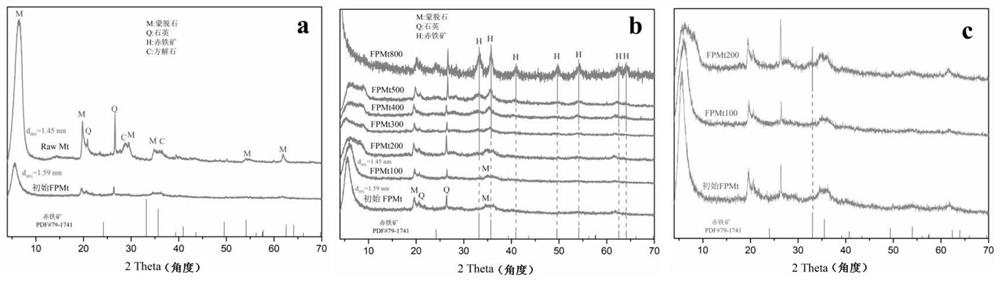

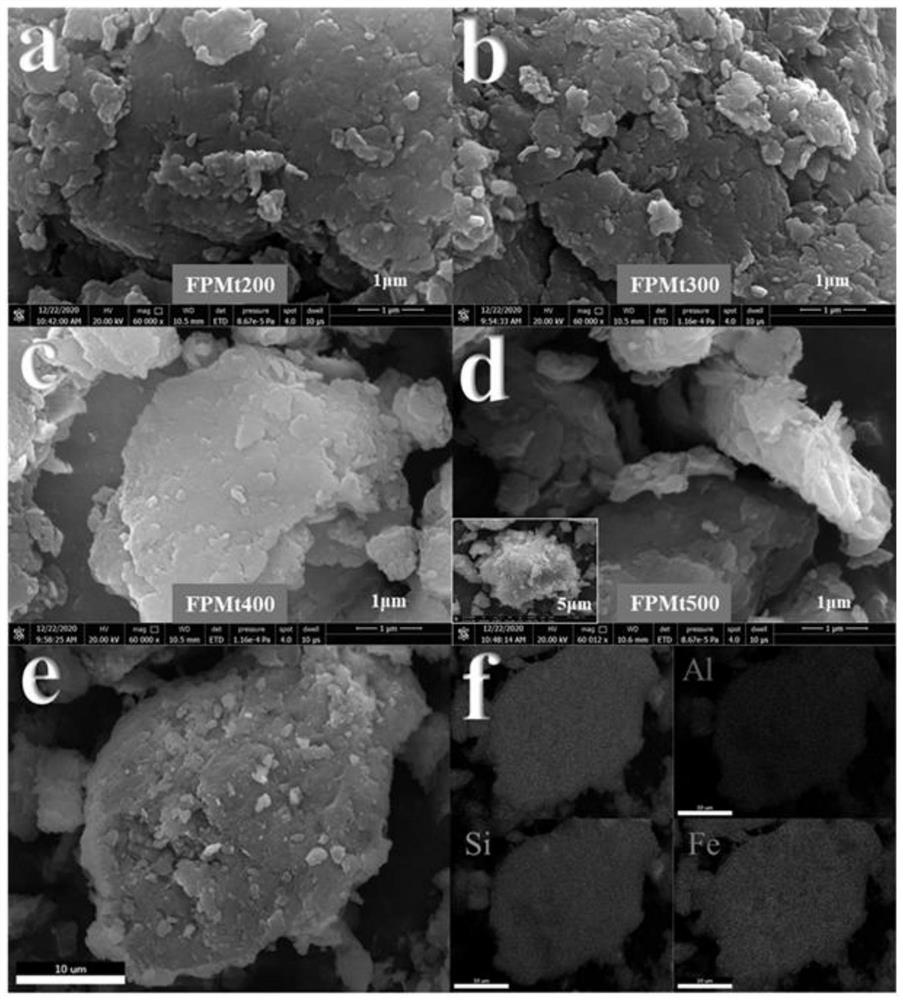

[0035] Preparation of Example 1 Iron Pillar Supported Montmorillonite Composite Material

[0036] (1) Preparation of montmorillonite suspension

[0037] Weigh 5 g of Na-montmorillonite (a purity of more than 90%, and a particle size of 100-200 mesh), disperse it in 245 mL of deionized water, and stir vigorously at room temperature (about 25°C) for 1 hour to obtain the content of Na-montmorillonite. 2% montmorillonite suspension;

[0038] (2) Preparation of iron pillar proppant

[0039] Weigh 5.3g Na 2 CO 3, slowly added to 250mL Fe(NO 3 ) 3 In aqueous solution (Na 2 CO 3 The concentration is 0.2mol / L), and vigorously stirred for 2h to form a translucent reddish-brown iron proppant solution, which was aged at room temperature for 24h;

[0040] (3) Preparation of iron pillared montmorillonite suspension:

[0041] Mix the montmorillonite suspension and iron pillared agent solution according to the ratio of [Fe] / Mt=10mmoL / g ([Fe] represents iron element), and then vigorou...

Embodiment 2

[0046] Preparation of Example 2 Iron Pillar Supported Montmorillonite Composite Material

[0047] (1) Preparation of montmorillonite suspension

[0048] Weigh 5 g of Na-montmorillonite (a purity of more than 90%, and a particle size of 100-200 mesh), disperse it in 245 mL of deionized water, and stir vigorously at room temperature (about 25°C) for 1 hour to obtain the content of Na-montmorillonite. 2% montmorillonite suspension;

[0049] (2) Preparation of iron pillar proppant

[0050] Weigh 2.65g Na 2 CO 3 , slowly added to 125mL Fe(NO 3 ) 3 solution, and vigorously stirred for 2 hours to form a translucent reddish-brown iron proppant solution, which was aged at room temperature for 24 hours;

[0051] (3) Preparation of iron-pillared montmorillonite suspension

[0052] The sodium-based montmorillonite suspension and the iron pillared montmorillonite suspension were mixed according to the ratio of [Fe] / Mt=5mmoL / g, then vigorously stirred for 2h to make it fully uniform ...

Embodiment 3

[0057] Preparation of Example 3 Iron Pillar Supported Montmorillonite Composite Material

[0058] (1) Preparation of montmorillonite suspension

[0059] Weigh 5 g of Na-montmorillonite (a purity of more than 90%, and a particle size of 100-200 mesh), disperse it in 245 mL of deionized water, and stir vigorously at room temperature (about 25°C) for 1 hour to obtain the content of Na-montmorillonite. 2% montmorillonite suspension;

[0060] (2) Preparation of iron pillar proppant

[0061] Weigh 7.95g Na 2 CO 3 , slowly added to 375mL Fe(NO 3 ) 3 aqueous solution and vigorously stirred for 2 hours to form a translucent reddish-brown iron proppant solution, and aged at room temperature for 24 hours;

[0062] (3) Preparation of iron-pillared montmorillonite suspension

[0063] Mix the montmorillonite suspension and the iron pillared montmorillonite solution at the ratio of [Fe] / Mt=15mmoL / g, then vigorously stir for 2h to make it fully uniform to obtain the iron pillared montm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com