An olive structure and preparation method for detecting formaldehyde

A technology of olivine structure and gas-sensing materials, which is applied in the field of olivine-structure gas-sensing materials and its preparation, can solve the problems that cannot fully meet the sensitivity, selectivity, long-term stability, rapid response-recovery indoor air detection, etc. Achieve excellent selectivity, low preparation cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

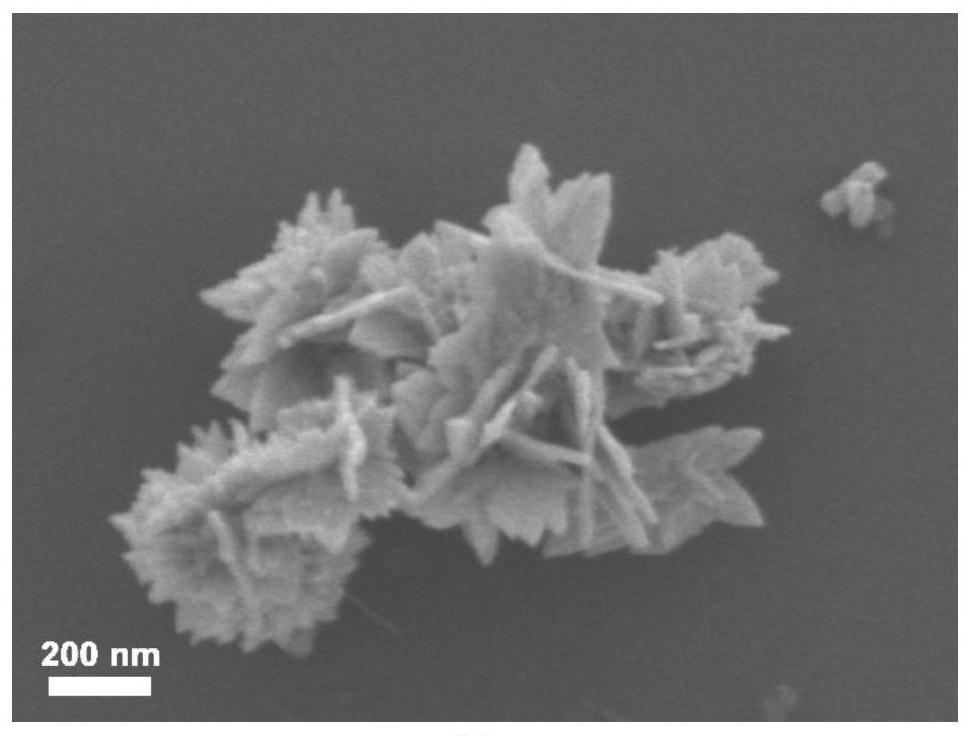

[0030] Example 1: Preparation of an olivine structure gas sensing material

[0031] (1) 5mmol of sodium hydroxide (NaOH) is added to 5mL of deionized water, and the configuration concentration is an alkaline solution of 1mol / L;

[0032] (2) Weigh 26.2 mg of germanium oxide (GeO 2 ), added to the alkaline solution of step (1), stirring and dissolving; the molar concentration of germanium solution is 0.05mol / L;

[0033] (3) Weigh 114.2 mg cadmium chloride 2.5 hydrate (CdCl 2 ·2.5H 2 0), added to 5mL of deionized water, the configuration concentration is 0.1mol / L cadmium solution;

[0034] (4) Mix the solutions of step (2) and step (3), add 50 mg of surfactant polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123), and stir for 15 minutes ; The mixed solution after stirring was transferred to the reactor, and the hydrothermal reaction was carried out at 200 ° C for 12 hours;

[0035] (5) After the reaction kettle is cooled to room temperature, th...

Embodiment 2

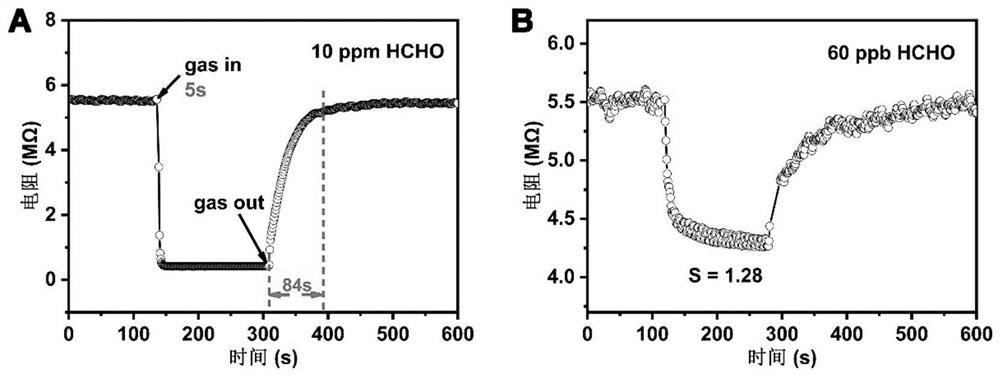

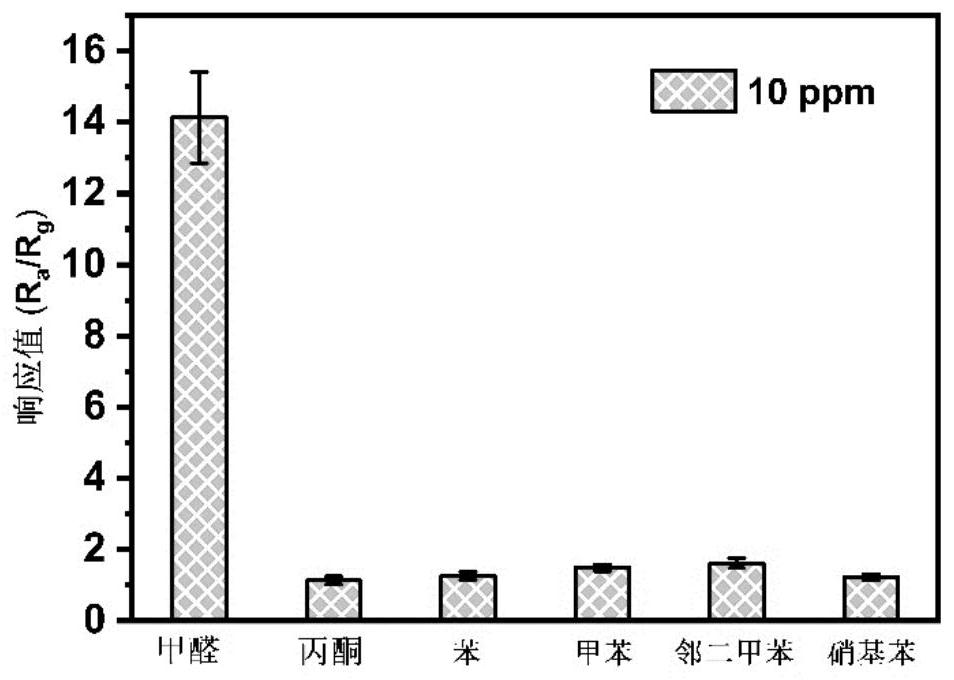

[0036]Example 2: Fabrication and gas-sensing properties of gas-sensing devices based on cadmium germanate nanosheets

[0037] The gas sensor is mainly composed of alumina ceramic tube, nickel-chromium alloy heating wire and base. The alumina ceramic tube has a length of 4mm and a diameter of 1mm. Ring-shaped, separate and parallel gold electrodes are distributed on both ends of the outer surface of the ceramic tube. The distance between the two gold electrodes is 1.15mm, the width of the gold electrodes is 0.5mm, and two platinum wires are connected to each gold electrode. wire. The heating part is a nickel-chromium alloy heating wire, which passes through the inside of the alumina ceramic tube, and its function is to provide a stable working temperature for the gas sensor.

[0038] The preparation steps of the gas sensor are as follows: (1) Put 50 mg of the cadmium germanate nanosheets prepared in Example 1 in an agate mortar, add 10 mL of 95% absolute ethanol by mass, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com