Polyimide aerogel fiber as well as preparation method and application thereof

An airgel fiber and polyimide technology, which is applied in fiber treatment, fiber chemical characteristics, wet spinning, etc., can solve the problems of continuous preparation and poor mechanical properties of polyimide airgel fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a kind of preparation method of polyimide airgel fiber, and this method comprises the following steps:

[0037] 1) disperse water-soluble polyamic acid and triethylamine in water, and obtain polyamic acid hydrogel spinning solution after sol-gel;

[0038] 2) extruding and spinning the polyamic acid hydrogel spinning solution into a water / alcohol / acid mixed coagulation bath for solvent replacement to obtain polyamic acid hydrogel fibers with a skin-core structure;

[0039] 3) After the polyamic acid hydrogel fiber is drawn, it is sent into a low-temperature tank to form an ice template, and after collection, it is sequentially freeze-dried and thermally imidized to obtain a polyimide airgel fiber with a skin-core structure. The fiber can be used in thermal insulation materials.

[0040]In step 1), the preparation process of water-soluble polyamic acid is: dissolving the diamine monomer and the dibasic anhydride monomer in a polar solvent, then pol...

Embodiment 1

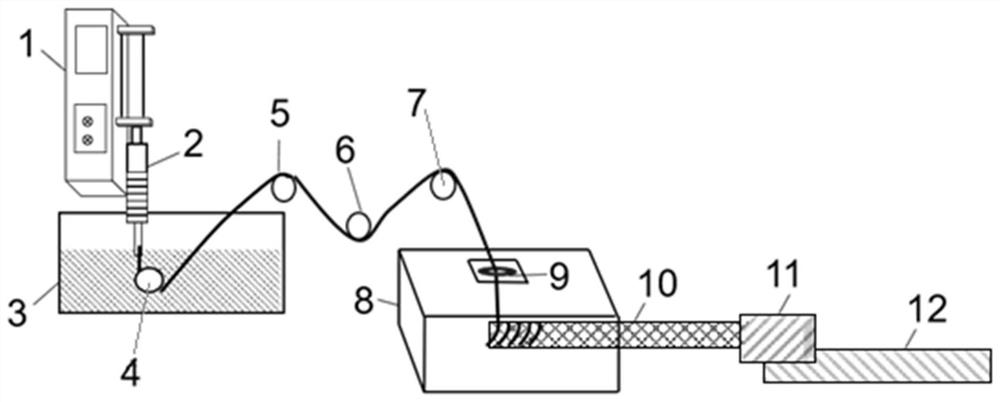

[0044] A device for preparing polyimide airgel fibers such as figure 1 As shown, it includes fiber extrusion unit, coagulation unit, drafting unit, freezing unit and collection unit.

[0045] The fiber extrusion unit includes a syringe pump 1 and a syringe 2, the syringe 2 is installed on the syringe pump 1, and the speed of extruding the spinning solution is controlled by the syringe pump 1. The syringe pump 1 squeezes the piston of the syringe 2 to control the extrusion of the spinning solution. The syringe 2 is a syringe with a volume of 20ml, and the flow rate of the syringe pump 1 to squeeze the piston is selected to be 0.1ml / min.

[0046] The coagulation unit includes a coagulation tank 3 and a coagulation bath. Solidification tank 3 can select glass tank or polytetrafluoroethylene tank for use. The coagulation bath is a mixed solution of water, ethanol, and hydrochloric acid, and the volume ratio is 5:5:0.3.

[0047] The drafting unit includes four drafting wheels, t...

Embodiment 2

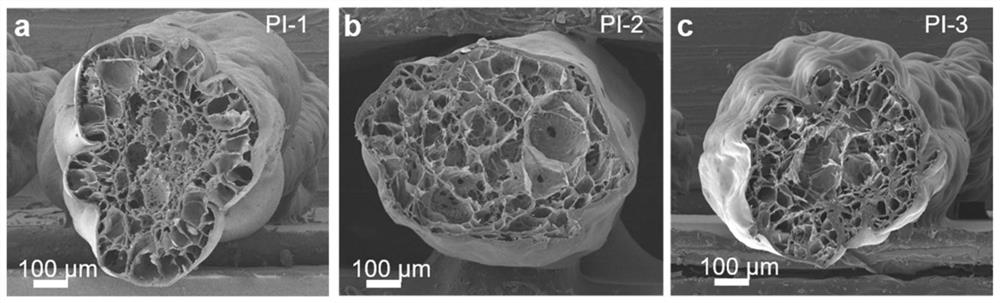

[0054] The difference from Example 1 is that the volume ratio of water, ethanol, and hydrochloric acid in the coagulation bath is 5:5:0.2, and the obtained polyimide airgel fiber is designated as PI-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com