Treatment process of nickel-containing alloy powder in hydrochloric acid system

A technology of nickel alloy powder and treatment process is applied in the field of treatment technology of nickel-containing alloy powder in a hydrochloric acid system, which can solve the problems of difficult recovery of nickel alloy powder and the like, and achieve the effect of realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

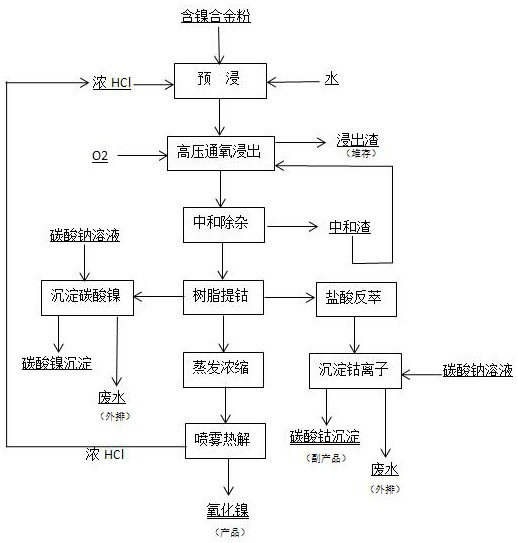

Image

Examples

Embodiment 1

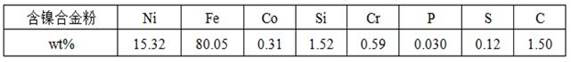

[0020] The composition of the nickel-containing alloy powder in this embodiment is shown in Table 1.

[0021] Table 1 Composition of nickel-containing alloy powder (wt%)

[0022]

[0023] The hydrochloric acid system treatment process of the nickel-containing alloy powder comprises the following steps:

[0024] (1) Pre-soaking of nickel-containing alloy powder: Mix nickel-containing alloy powder, water and concentrated hydrochloric acid (36wt%) at a ratio of 1:8:0.25 and then stir for pre-soaking. The pre-soaking temperature is 60°C and the pre-soaking time is 1 hour;

[0025] (2) High-pressure oxygen leaching: Pour the prepreg slurry into the autoclave, raise the temperature to 150°C, feed oxygen, oxygen partial pressure 0.2Mpa, reaction pressure 0.7Mpa, reaction time 1.5h, cool down and liquid-solid Separation, the output leaching slag is stored, and the leachate enters the neutralization and impurity removal process;

[0026] (3) Neutralization and impurity removal: Ad...

Embodiment 2

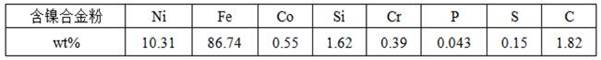

[0031] The composition of the nickel-containing alloy powder in this embodiment is shown in Table 2.

[0032] Table 2 Composition of nickel-containing alloy powder (wt%)

[0033]

[0034] The hydrochloric acid system treatment process of the nickel-containing alloy powder comprises the following steps:

[0035] (1) Pre-soaking of nickel-containing alloy powder: Mix nickel-containing alloy powder, water and concentrated hydrochloric acid (36wt%) at a ratio of 1:8:0.3 and then stir for pre-soaking. The pre-soaking temperature is 65°C and the pre-soaking time is 1 hour;

[0036] (2) High-pressure oxygen leaching: Pour the prepreg slurry into the autoclave, raise the temperature to 160°C, feed oxygen, oxygen partial pressure 0.2Mpa, reaction pressure 0.8Mpa, reaction time 1h, cooling and liquid-solid separation , the output leaching slag is piled up, and the leachate enters the neutralization and impurity removal process;

[0037] (3) Neutralization and impurity removal: Add ...

Embodiment 3

[0042] The composition of the nickel-containing alloy powder in this embodiment is shown in Table 3.

[0043] Table 3 Composition of nickel-containing alloy powder (wt%)

[0044]

[0045] The hydrochloric acid embodiment treatment process of the nickel-containing alloy powder comprises the following steps:

[0046] (1) Pre-soaking of nickel-containing alloy powder: Mix nickel-containing alloy powder, water and concentrated hydrochloric acid (36wt%) at a ratio of 1:10:0.25, then stir for pre-soaking. The pre-soaking temperature is 60°C, and the pre-soaking time is 1 hour;

[0047] (2) High-pressure oxygen leaching: Pour the prepreg slurry into the autoclave, raise the temperature to 150°C, feed oxygen, oxygen partial pressure 0.2Mpa, reaction pressure 0.7Mpa, reaction time 1.5h, cool down and liquid-solid Separation, the output leaching slag is stored, and the leachate enters the neutralization and impurity removal process;

[0048] (3) Neutralization and impurity removal:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com