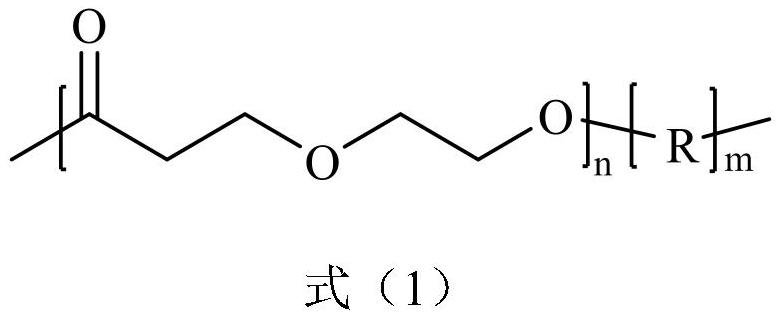

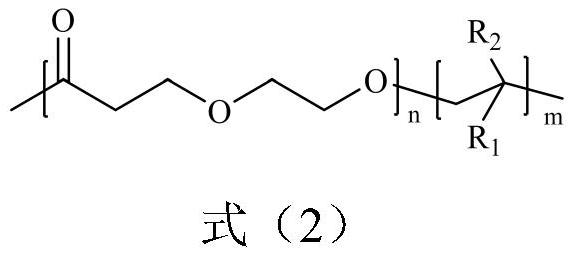

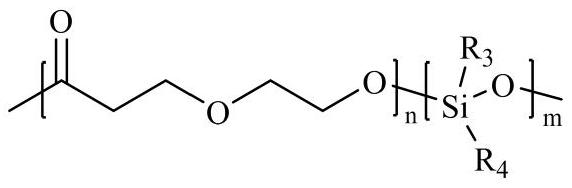

Poly (1, 5-dioxepane-2-ketone)-based block polymer as well as preparation method and application thereof

A technology of dioxepane and block polymers, which is applied in the field of poly-based block polymers and its preparation, can solve the problems of low ionic conductivity and inability to meet the ionic conductivity of electrolytes, and achieve simple preparation process , Improve mechanical properties and thermal stability, wide electrochemical window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. First heat the Schlenk bottle with the magnet and vacuumize it, replace the nitrogen back and forth three times, and remove the water and air. Rapid addition of 1,5-dioxepan-2-one (DXO) (3.48 g, 30 mmol), benzyl alcohol (BnOH) (108 mg, 1 mmol), 5 mL THF under nitrogen, "freeze vacuum-thaw" Three times, 1,8-diazabicycloundec-7-ene (DBU) (152 mg, 1 mmol) was then added under nitrogen. React at 25°C for 6h, add a small amount of hydrochloric acid / methanol mixed solvent to terminate the reaction, use excess diethyl ether as a precipitating agent, and dry at room temperature to obtain poly(1,5-dioxepan-2-one homopolymer) ( PDXO 30 ).

[0058] 2. Add PDXO 30 (3g, 1mmol), 10mLCH 2 Cl 2 Add a three-necked flask placed in a low-temperature reactor at -5°C, and dissolve 2-bromoisobutyryl bromide (345 mg, 1.5 mmol) in 5 mL of CH 2 Cl 2 and added dropwise into the above-mentioned three-necked flask, reacted at -5°C for 2h after the dropwise addition, and then raised the t...

Embodiment 2

[0066] The difference from Example 1 is that the amount of PS described in step 3 is (5.20g, 50mmol), and other implementation conditions are the same as those in Example 1 for synthesizing PDXO 30 -b-PS 30 The block polymer electrolyte is the same to make PDXO 30 -b-PS 50 block polymer electrolytes. By analyzing the polymer electrolyte, M n = 8000 g / mol of PDXO 30 -b-PS 50 Block polymer electrolytes in which the block PDXO:PS molar ratio is 3:5.

Embodiment 3

[0068] The difference from Example 1 is that the amount of PS described in step 3 is (1.04g, 10mmol), and other implementation conditions are the same as those in Example 1 for the synthesis of PDXO 30 -b-PS 30 The block polymer electrolyte is the same to make PDXO 30 -b-PS 10 block polymer electrolytes. By analyzing the polymer electrolyte, M n = 4000 g / mol of PDXO 30 -b-PS 10 Block polymer electrolytes in which the block PDXO:PS molar ratio is 3:1.

[0069] Characterize the performance of the block polymer electrolyte obtained in Examples 1-3, and the test results are shown in Table 1. It can be seen from Table 1 that in the PDXO-b-PS block polymer electrolyte, with the PDXO block The room temperature ionic conductivity of the electrolyte increases as the content increases, indicating that the PDXO block in the PDXO-b-PS block polymer electrolyte is beneficial to Li + Transmission.

[0070] The performance of the block polymer electrolyte obtained in table 1 embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com