Transparent heat-resistant fully-degradable component polylactic acid composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of transparent heat-resistant fully degradable component polylactic acid composite material and its preparation, can solve the problems of low molecular chain flexibility, limited product application, limited effect of improving interface compatibility HDT, etc. , to achieve the effect of improving transparency, heat resistance, toughness and transparency, and improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

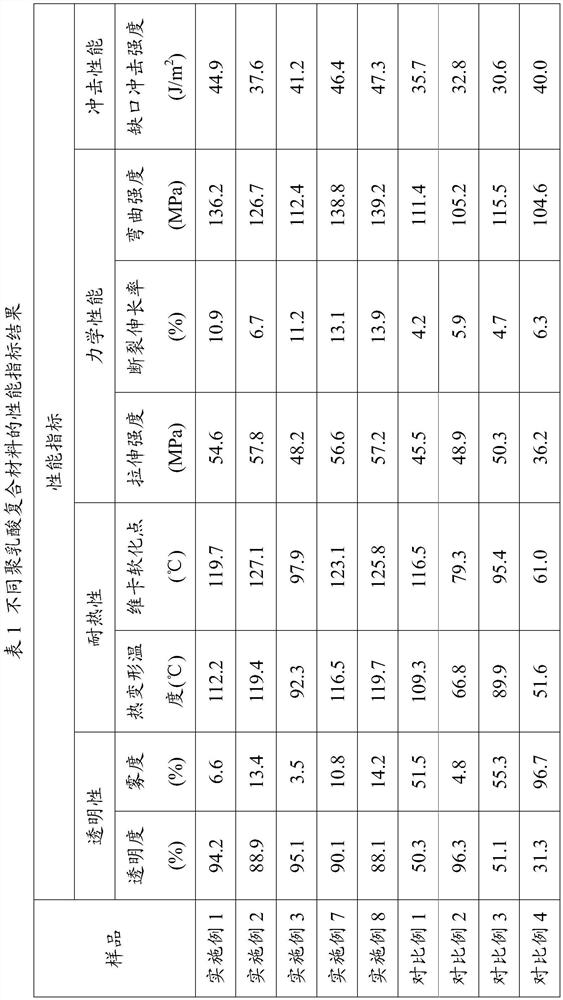

Examples

preparation example Construction

[0036] Second, the present invention provides a method for preparing a transparent heat-resistant fully degradable polylactic acid composite material, comprising the following steps:

[0037] S1 drying polylactic acid and high molecular weight polylactic acid, standby;

[0038] S2 High-molecular-weight polylactic acid and β-nucleating agent are sequentially pre-mixed-melt-blended, extruded and granulated, and then dried to obtain nucleated masterbatches;

[0039] The S3 nucleating masterbatch and polylactic acid are sequentially pre-mixed-melt-blended, extruded and granulated, and then dried to obtain a polylactic acid composite material.

[0040] In the present invention, in S1, the drying temperature is 60-80° C., and the drying time is 4-8 hours.

[0041] In the present invention, in S2, the temperature of melt blending is 160-180°C.

[0042] In the present invention, in S3, the temperature of melt blending is 155-175°C.

[0043] In the present invention, in S2 and S3, t...

Embodiment 1

[0047] A transparent heat-resistant fully degradable polylactic acid composite material, each component is calculated in parts by weight,

[0048] 100 parts of L-polylactic acid, 10 parts of high molecular weight L-lactic acid, 1 part of TMB-5, 0.3 parts of antioxidant 1010. The molecular weight of L-polylactic acid is 1*10 5 g / mol, the molecular weight of high molecular weight L-polylactic acid is 2*10 6 g / mol.

[0049] Its preparation method is,

[0050] S1 Dry L-polylactic acid and high molecular weight L-polylactic acid at 60-80°C for 6-8 hours for later use;

[0051] S2 High molecular weight L-polylactic acid and β-nucleating agent are physically blended first, and then added to the extrusion process to melt, extrude and granulate. 8h drying treatment to obtain the nucleating masterbatch;

[0052] S3 nucleating masterbatch is first physically blended with L-polylactic acid and antioxidant 1010. After physical blending, it is melt-extruded and granulated. The polylacti...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is that the distribution ratio of each component is different.

[0056] A transparent heat-resistant fully degradable polylactic acid composite material, each component is calculated in parts by weight,

[0057] 100 parts of L-polylactic acid, 15 parts of high molecular weight L-lactic acid, 1.5 parts of TMB-5, 0.3 parts of antioxidant 1010.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com