Composite flame retardant and its preparation method and application

A technology for compounding flame retardants and flame retardants, applied in chemical instruments and methods, lamination, coatings, etc., can solve the problem of slowing down the curing rate, reducing the curing speed of resin-based composite materials, affecting the curing speed of resin-based composite materials problems, to achieve good solvent resistance, improved thermal and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides the preparation method of described composite flame retardant, mainly comprises the following steps:

[0050] S11, blending a thermoplastic elastomer and a non-reactive compatibilizer to obtain a premix, wherein the blending temperature is greater than the melting temperature of the thermoplastic elastomer;

[0051] S12, blending the premix with a reactive compatibilizer and a plasticizer to obtain a first mixture, wherein the plasticizer includes a reactive plasticizer and / or a non-reactive plasticizer;

[0052] S13, blending the first mixture with a flame retardant to obtain a second mixture; and

[0053] S14, cooling the second mixture, granulating, and pulverizing to obtain a composite flame retardant.

[0054] In order to fully melt the thermoplastic elastomer, in step S11, the temperature difference between the blending temperature and the melting temperature of the thermoplastic elastomer is 15°C-30°C.

[0055] It should be n...

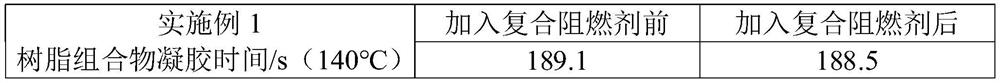

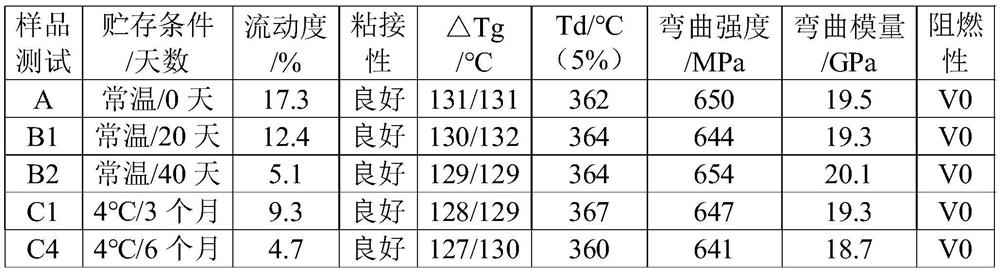

Embodiment 1

[0089] 60 parts by weight of EMPPS (olefinic thermoplastic elastomer, the mass ratio of soft segment and hard segment is about 7:3, and the melting temperature is 170 ° C) is first placed in a vacuum oven at 50 ° C for 6 hours, and the dried EMPPS and 0.8 parts by weight of nano-modified organic montmorillonite was placed in an internal mixer, blended at 190°C for 3 minutes, and 1.5 parts by weight of carboxyl-terminated liquid nitrile rubber and 1.6 parts by weight of bisphenol A-diglycidyl ether were added. Blending for another 2.5 minutes, finally adding 28 parts by weight of ammonium polyphosphate and 12 parts by weight of aluminum hydroxide, blending for 5 minutes and mixing uniformly, the obtained mixture was cooled, granulated, and frozen and pulverized into particles with a particle size of 5 μm-30 μm. powder to obtain a composite flame retardant, and the melting temperature of the composite flame retardant is below 155°C.

[0090] With the isophthalic acid hydrazide o...

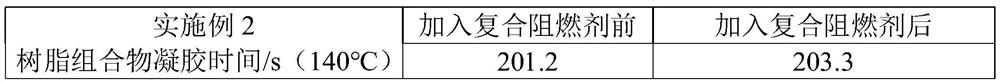

Embodiment 2

[0101] 45 parts by weight of TPEE (polyether ester thermoplastic elastomer, the mass ratio of the soft segment and the hard segment is 8.5:1.5, and the melting temperature is 175 ° C) is first placed in a vacuum oven at 50 ° C for 5 hours, and the dried TPEE and Put 0.4 parts by weight of nanocellulose into an internal mixer, blend for 2 minutes at 200°C, add 1.2 parts by weight of liquid isoprene rubber with carboxyl-terminated liquid isoprene rubber and 0.7 parts by weight of bisoxazoline, and then blend for 4 Minutes, finally add 18 parts by weight of phosphine oxide and 10 parts by weight of melamine cyanurate, blend for 4 minutes and mix evenly, the obtained mixture is cooled, granulated, and frozen and pulverized into a powder with a particle size of 5 μm-30 μm. A composite flame retardant is obtained, and the melting temperature of the composite flame retardant is below 160°C.

[0102] 4.5 parts by weight of sebacic acid dihydrazide, 3.0 parts by weight of chlorendic an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com