New crystal form NTO single-compound explosive and preparation method thereof

A technology of elemental explosive and crystal form control agent, which is applied to single substance as explosives, explosives processing equipment, explosives, etc., can solve the problem of affecting the life and use effect of weapons and equipment, unfavorable mixed preparation and use of explosives, and restricting the wide application of NTO, etc. problems, to achieve the effects of small mechanical sensitivity, low production cost and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 50 mL of anhydrous methanol into the three-necked flask, then add 0.56 g of NTO and 0.04 g of ATO, connect the flask to a condensation reflux device, and raise the temperature to 60 ° C under constant stirring to completely dissolve NTO and ATO. °C / min, the temperature was lowered slowly, and white crystals gradually precipitated at the bottom of the flask. After cooling down to 20 °C, filtered, washed, and dried to obtain γ-NTO crystals.

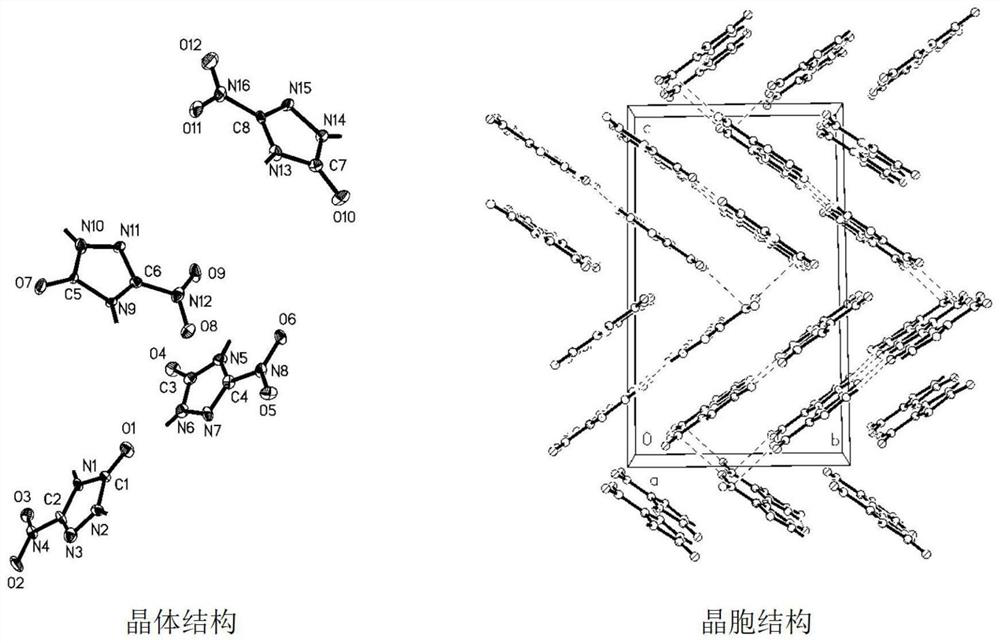

[0028] The structure of γ-NTO was confirmed by single crystal X-ray diffractometer, and its crystal structure and unit cell structure are as follows: figure 1 shown. The molecular formula of γ-NTO is C 2 h 2 N 4 o 3 , belongs to monoclinic crystal system, Pc space group, density is 1.907g / cm 3 (293K). Its unit cell parameters are: α=90°, β=98.420(3)°, γ=90°; Z=8. Its single crystal structure data is as follows:

[0029]

[0030]

Embodiment 2

[0032] Add 100mL of anhydrous methanol into the three-necked flask, then add 1.12g of NTO and 0.15g of ATO, connect the flask to a condensation reflux device, raise the temperature to 60°C under constant stirring, to completely dissolve NTO and ATO, and keep warm for 2 hours at 2°C Slowly lower the temperature per minute, and white crystals gradually precipitate at the bottom of the flask. After cooling down to 20°C, filter, wash, and dry to obtain γ-NTO crystals. The thermal decomposition temperature of the γ-NTO explosive is 277.59°C, which is higher than that of α-NTO (275.31°C), indicating that the formation of γ-NTO has improved the thermal stability of NTO. The characteristic drop height value of the impact sensitivity of the γ-NTO explosive is 300cm (2.5kg drop weight), which is higher than that of α-NTO (280cm), indicating that the formation of γ-NTO has reduced the impact sensitivity of NTO and improved the impact sensitivity of NTO. security.

Embodiment 3

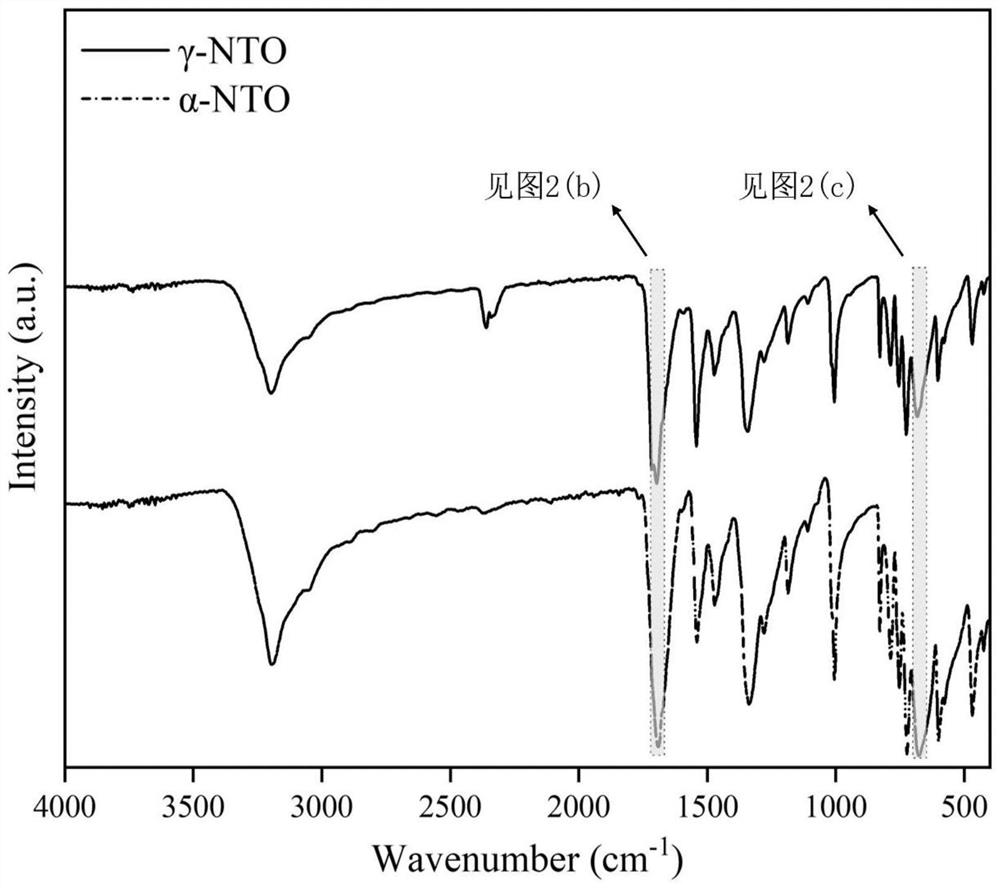

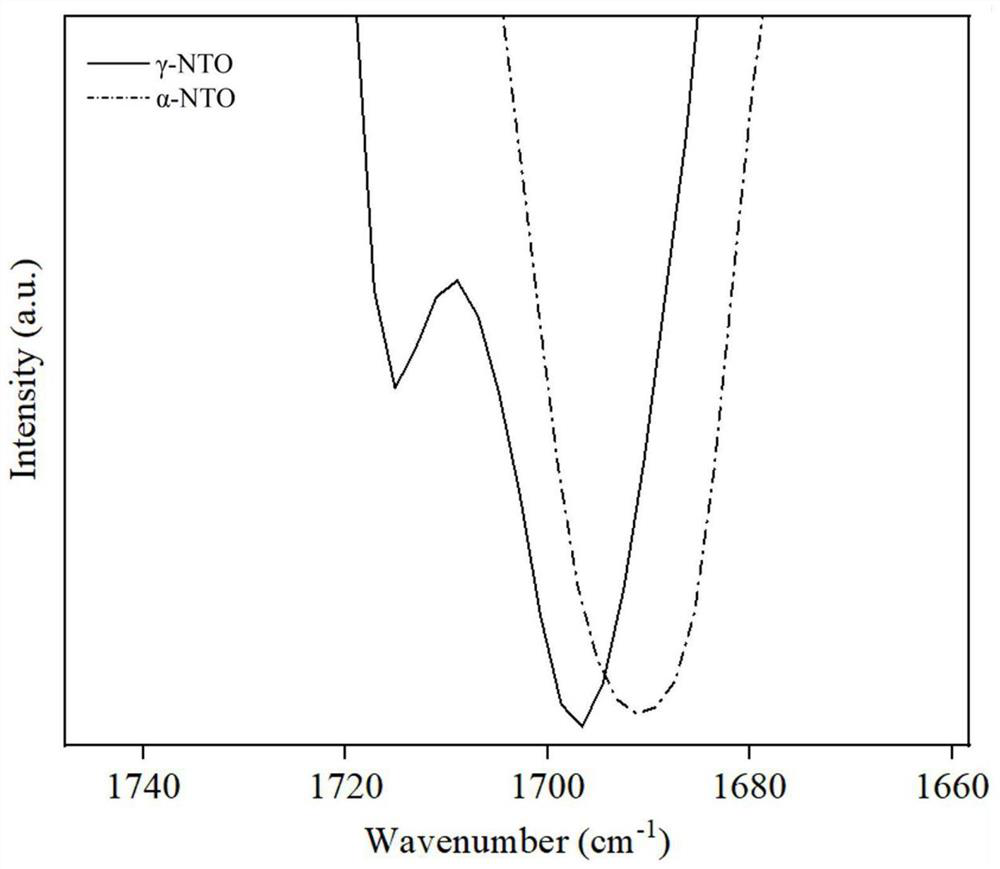

[0034] Add 50mL of anhydrous methanol into the three-neck flask, then add 0.56gNTO and 0.32gATO, connect the flask to a condensation reflux device, raise the temperature to 60°C under constant stirring, so that NTO and ATO are completely dissolved, and keep warm for 0.5 hours at 1°C Slowly lower the temperature per minute, and white crystals gradually precipitate at the bottom of the flask. After cooling down to 20°C, filter, wash, and dry to obtain γ-NTO crystals. The acidic dissociation constant pKa value of the γ-NTO explosive was measured to be 4.95, which is higher than that of α-NTO (pKa=3.76), which may be due to the 4-position of the NTO triazole ring in the γ-NTO unit cell structure. H forms stronger hydrogen bonds, which makes the dissociation of hydrogen difficult, thus reducing the acidity of NTO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com