Powder throwing magnetic attraction type metal bar polishing device

A metal bar, polishing device technology, applied in grinding/polishing safety devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of accelerating metal corrosion, affecting coating adhesion and anti-corrosion ability, low pressure, etc. problem, to achieve the effect of increasing the grinding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

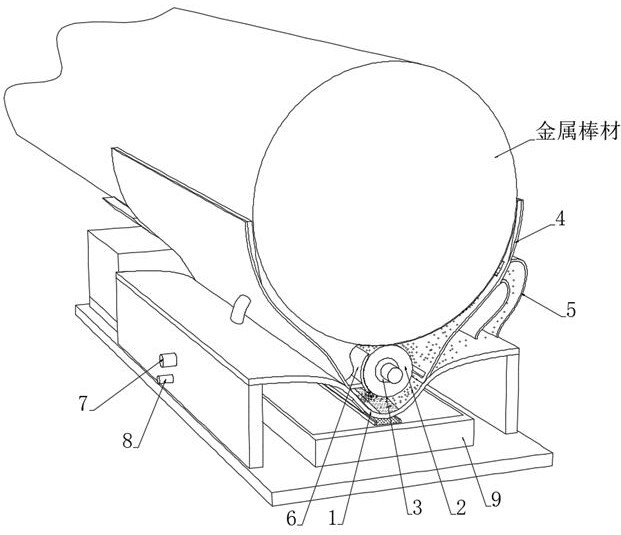

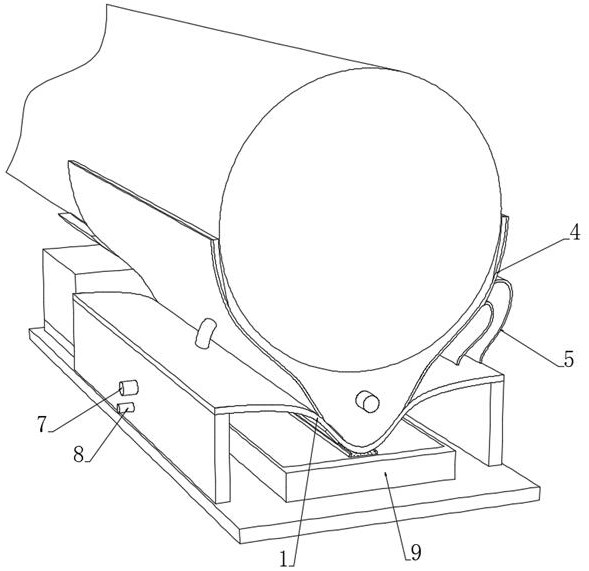

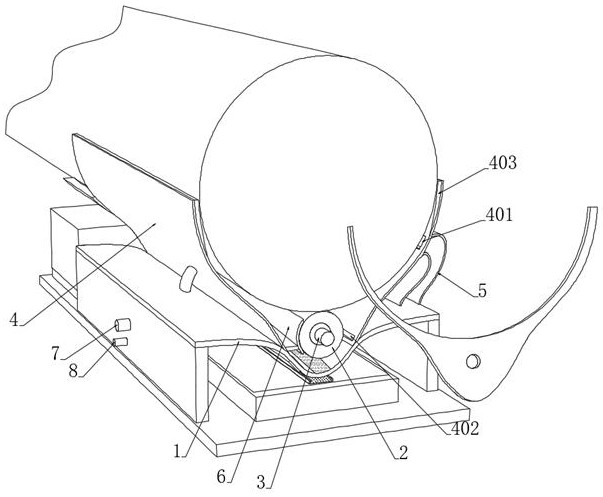

[0045] see Figure 1-3 , a polishing device for throwing magnetic suction metal rods, including a concave arc support 1 installed on a base, a control box is installed at the rear end of the base, and a control box located on a concave arc support is installed on the control box. The magnetic grinding roller 2 above the middle part of the support 1, the magnetic grinding roller 2 is embedded with the inner electromagnetic roller 3 fixedly connected with the control box, and the control system connected with the magnetic grinding roller 2 and the inner electromagnetic roller 3 is installed in the control box, The control system controls the rotation of the magnetic grinding roller 2. The control system controls the speed of the magnetic grinding roller 2 to meet the grinding requirements of different metal bars. The control system controls the internal power supply of the inner electromagnetic roller 3. This is an existing intelligent technology. , without going into too much d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com