Silk fibroin/hydroxyapatite composite material and its preparation method and application

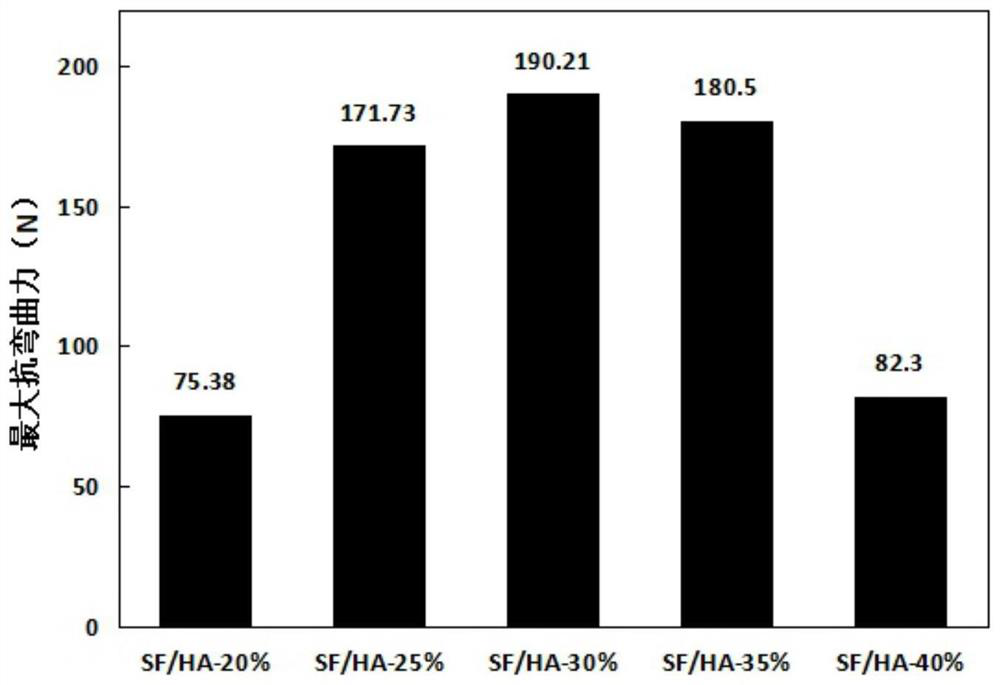

A technology of hydroxyapatite and silk fibroin, which is applied in the fields of clinical medicine and material science, can solve the problems of insufficient mechanical properties, uneven dispersion of hydroxyapatite, inability to process large-size bone nails, etc., and achieve obvious osteoinductivity , the effect of promoting bone defect recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

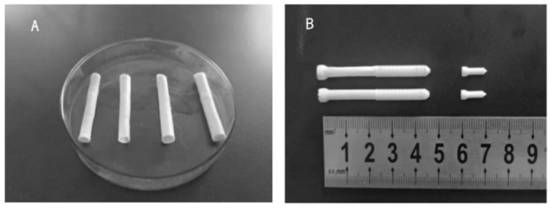

[0049] (1) Take 5g of silk fibroin protein powder, add hydroxyapatite nanoparticles, and use a vortex mixer and an ultrasonic oscillator to mix thoroughly. Wherein, the hydroxyapatite nanoparticles account for 0 wt% to 40 wt% of the total amount of the hydroxyapatite nanoparticles and the silk fibroin.

[0050] (2) According to the mixture of 35g of hydroxyapatite nanoparticles and silk fibroin per 100mL of hexafluoroisopropanol, the mixture of hydroxyapatite nanoparticles and silk fibroin powder is evenly dispersed in the hexafluoroisopropanol In isopropanol, keep it in an oven at 55°C for 0.5h to completely dissolve hydroxyapatite nanoparticles and silk fibroin powder, and remove air bubbles to obtain hydroxyapatite nanoparticles, silk fibroin, hexafluoro Mixture of isopropanol.

[0051] (3) Take the mixture out of the oven, add 5g of silk fibroin powder and the same amount of hydroxyapatite nanoparticles as in step (1), and add the same amount of hexafluoride as in step (2...

Embodiment 2

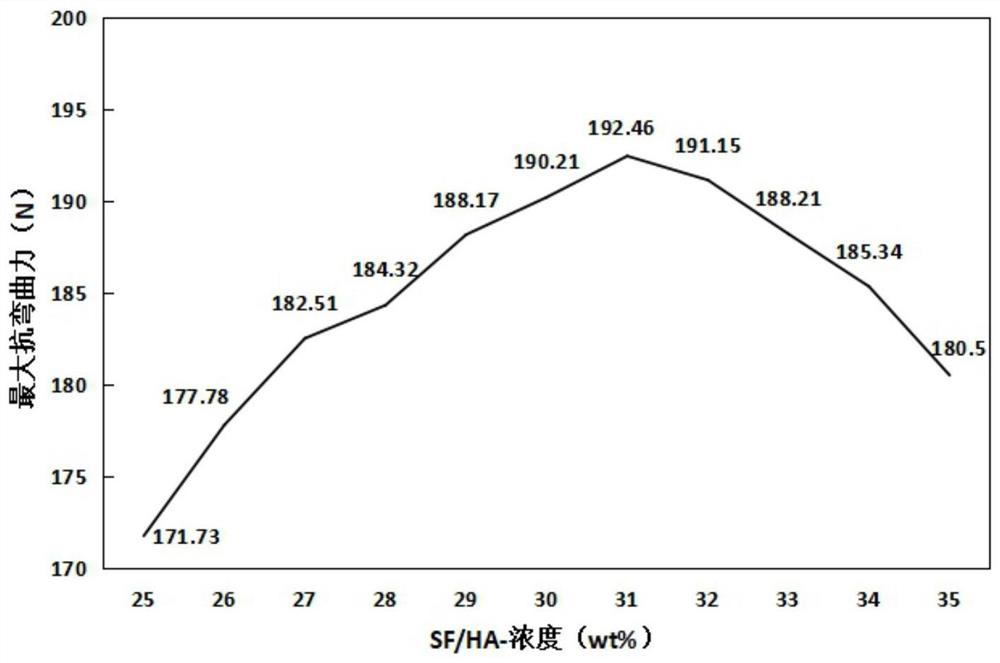

[0063] Get the rod (nHA / SF-31%) that the hydroxyapatite nanoparticle prepared in Example 1 accounts for 31wt% of the total amount of hydroxyapatite nanoparticle and silk fibroin, cut it into powder, and perform Fourier Leaf infrared spectroscopy detection to study the mechanism of silk fibroin performance enhancement after methanol treatment. At 1658cm- 1 , l545 cm- 1 and 1242cm- 1 The absorption peaks at the positions belong to the characteristic absorption peaks of amide I, amide II and amide III of the dry silk fibroin molecule (Silk), indicating that its secondary structure is a random coil; after methanol regeneration, the three characteristic peaks are transferred to 1634cm- 1 、1520cm- 1 and 1230cm- 1 , indicating that silk fibroin transforms from random coils to β-sheets, which is beneficial to increase the strength of silk fibroin / hydroxyapatite composites. In addition, in the infrared spectrum of silk fibroin / hydroxyapatite composites at 603cm- 1 and 565cm- 1 ...

Embodiment 3

[0065]Take the nHA / SF-31% screw prepared in Example 1, culture it at the ankle bone of rabbits, track the degradation of the nHA / SF-31% screw, and find that after culturing at the ankle bone of rabbits for 2 months, the nHA / SF-31 The gap between the % screw and the host bone tissue was significantly reduced, and no inflammatory cells were observed during the degradation of the nHA / SF-31% screw, indicating that the degradation products of silk fibroin / hydroxyapatite composites can be absorbed by the human body. The analysis found that the degradation products of the hydroxyapatite / silk fibroin composite material provided by the present invention in the human body are all non-toxic and non-irritating products: the degradation products of silk fibroin are amino acids and water, which can be absorbed by the human body; Apatite is the main component of human bone, and its degradation products are phosphate and calcium ions, which are non-toxic and can be metabolized out of the body....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com