Surface-modified selective laser cladding cobalt-chromium alloy and preparation method and application thereof

A technology of laser cladding and cobalt-chromium alloy, which is applied in the coating process and coating of metal materials, can solve the problems of less research on bonding performance, achieve compact bonding, improve metal-ceramic bonding performance, and increase metal-ceramic bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a surface-modified selective laser cladding cobalt-chromium alloy described in the above technical solution, comprising the following steps:

[0031] The selective laser cladding cobalt-chromium alloy is placed in an acid solution and subjected to corrosion treatment to obtain the corroded cobalt-chromium alloy;

[0032] The corroded cobalt-chromium alloy is placed in an electrolyte solution, and electrodeposition treatment is performed to obtain a surface-modified selective laser cladding cobalt-chromium alloy; the composition of the electrolyte solution includes nickel chloride 5-10g / L, chlorine Cobalt chloride 7-15g / L, chromium chloride 3-8g / L, tungsten chloride 8-12g / L, thiourea 3-6g / L and potassium pyrophosphate 20-30g / L.

[0033] In the invention, the selective laser cladding cobalt-chromium alloy is placed in an acid solution for corrosion treatment to obtain the corroded cobalt-chromium alloy. In the pr...

Embodiment 1

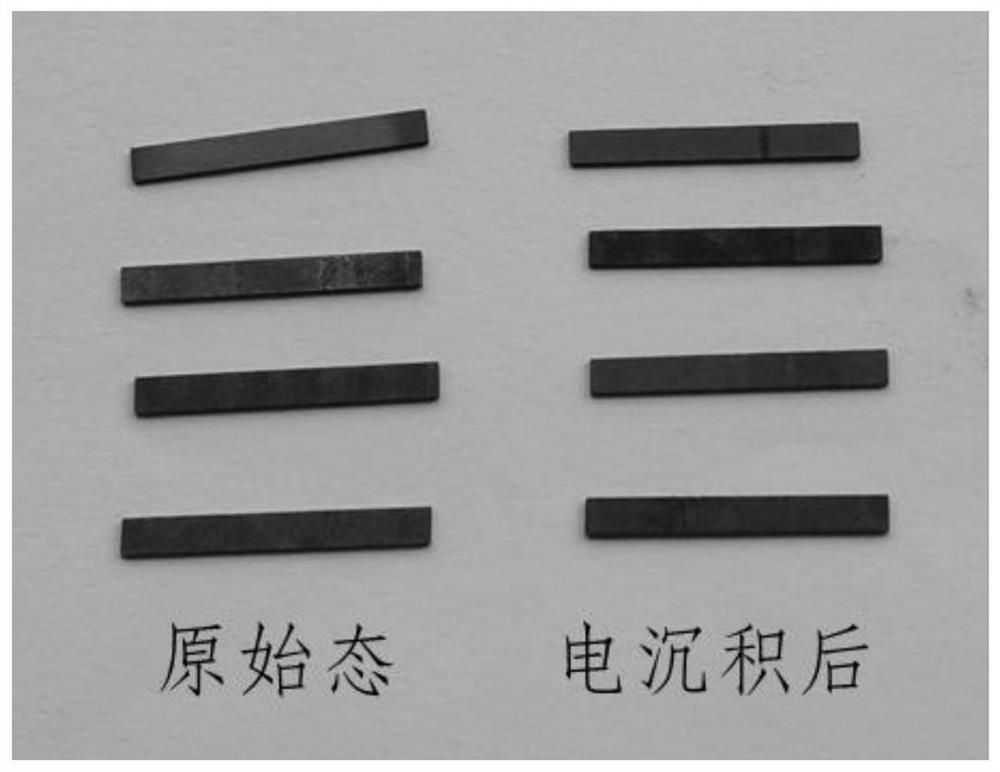

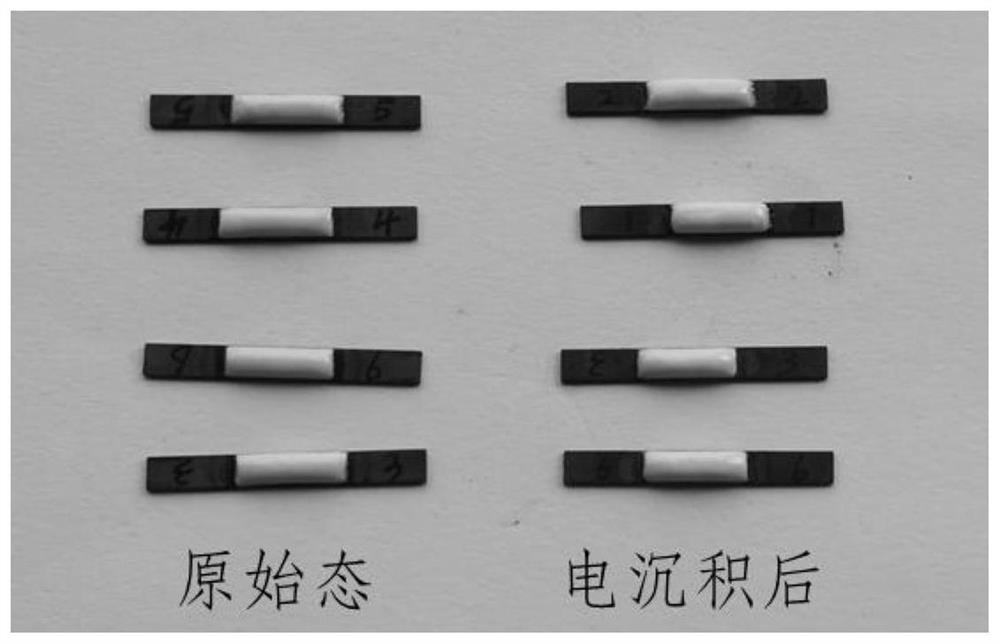

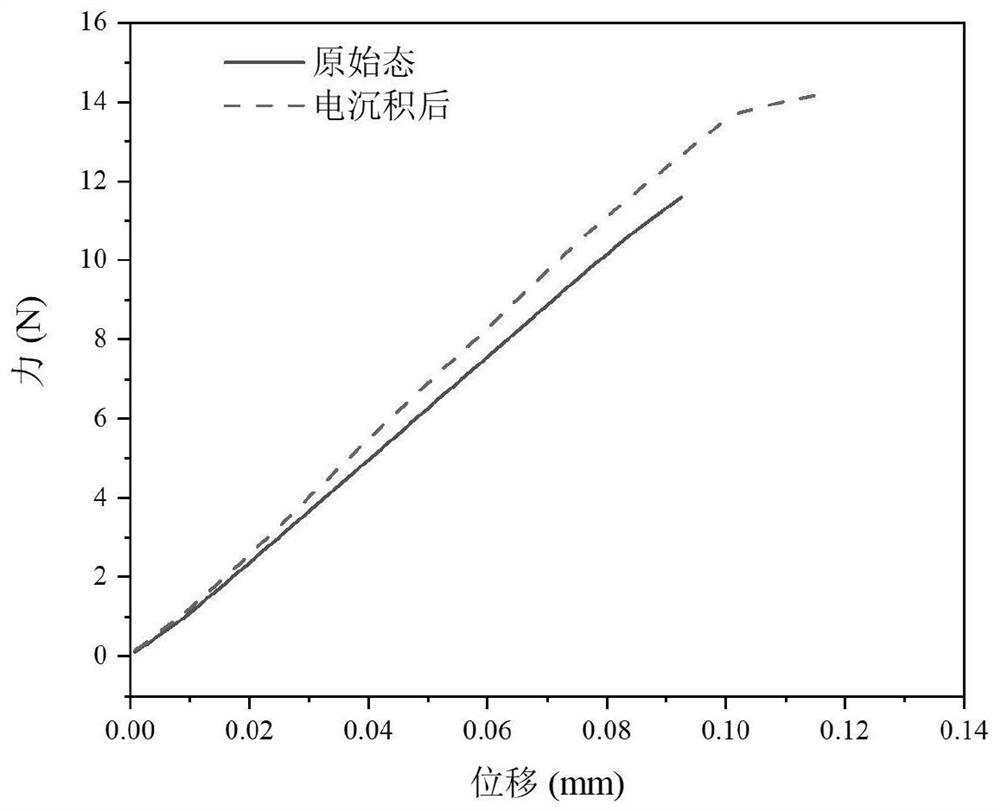

[0051] (1) The cobalt-chromium alloy powder whose chemical composition is Cr 25.15wt.%, W 5.36wt.%, Mo 4.09wt.%, Si 0.93wt.% and the balance of Co is printed with selective laser cladding equipment The block is then cut into 25mm×3mm×0.5mm selective laser cladding cobalt-chromium alloy sheet (original state) by EDM, such as figure 1 shown on the left.

[0052] (2) The selective laser cladding cobalt-chromium alloy sheet is placed in a mixed solution of copper sulfate and hydrochloric acid for corrosion treatment, the concentration of hydrochloric acid in the mixed solution of copper sulfate and hydrochloric acid is 5wt.%, and the concentration of copper sulfate %, the temperature of the corrosion treatment is controlled by a water bath at 25°C, and the corrosion treatment is performed for 2 minutes; then the obtained alloy is washed with water and ethanol to obtain a corroded cobalt-chromium alloy sheet;

[0053] (3) the cobalt-chromium alloy sheet after described corrosion i...

Embodiment 2

[0064] (1) The cobalt-chromium alloy powder whose chemical composition is Cr 25.23wt.%, W 5.06wt.%, Mo 4.78wt.%, Si 0.73wt.% and the balance of Co is printed with selective laser cladding equipment The block is then cut into 25mm×3mm×0.5mm selective laser cladding cobalt-chromium alloy sheets by EDM.

[0065] (2) The selective laser cladding cobalt-chromium alloy sheet is placed in a mixed solution of copper sulfate and hydrochloric acid for corrosion treatment, the concentration of hydrochloric acid in the mixed solution of copper sulfate and hydrochloric acid is 3wt.%, and the concentration of copper sulfate %, the temperature of the corrosion treatment is controlled by a water bath at 25°C, and the corrosion treatment is performed for 2 minutes; then the obtained alloy is washed with water and ethanol to obtain a corroded cobalt-chromium alloy sheet;

[0066] (3) the cobalt-chromium alloy sheet after described corrosion is placed in electrolytic solution, carries out electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com