High-transparency and high-heat-resistance copolyester resin and preparation method thereof

A copolyester and high heat-resistant technology, which is applied in the field of high-transparency and high-heat-resistant copolyester resin and its preparation, can solve the problems of poor thermal stability, poor transparency, gas clogging, etc., and achieve good heat resistance and reduce Effects of consumption and recovery of load, and solution to clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Example 1 Synthesis

[0128] (1) a solution of N 2 The reactor atmosphere was added dimethyl terephthalate, 67.96g (0.35mol), 2,2,4,4- tetramethyl-1,3-cyclobutanediol (cis content 62%) 30.28g ( 0.21mol), 3- methyl-1,5-pentanediol 37.22g (0.315mol) and dibutyltin oxide 0.2039g, and added primary stabilizer and auxiliary stabilizer 10100.068g 6260.034g, for 3h at 220 ℃, to give transesterification product; during the reaction, not observed in the solid line.

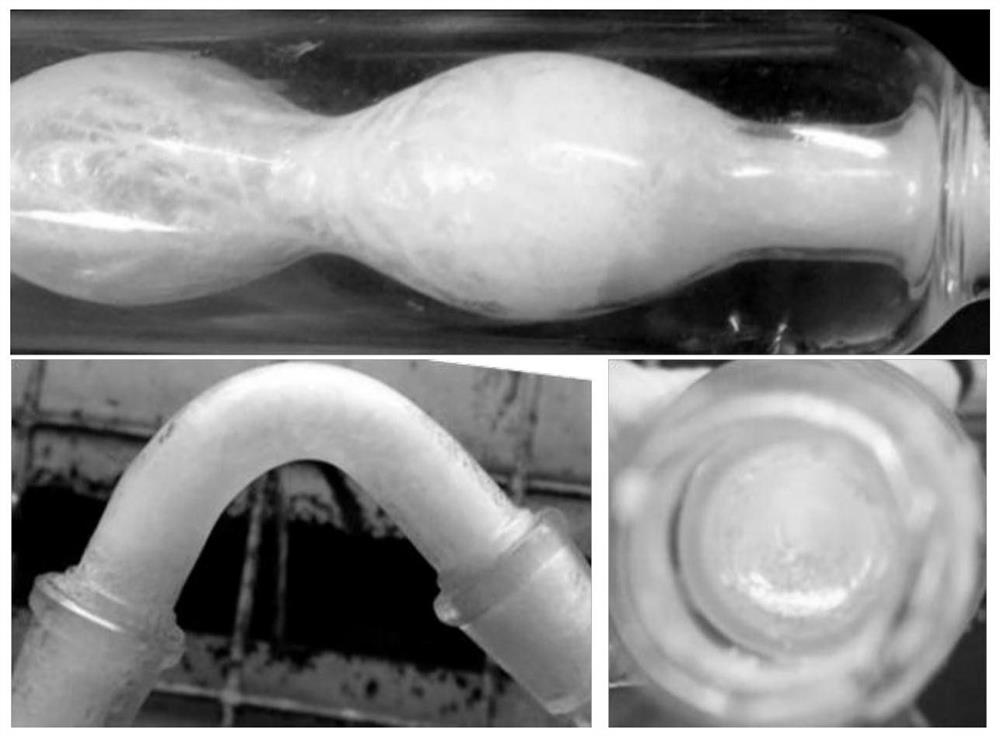

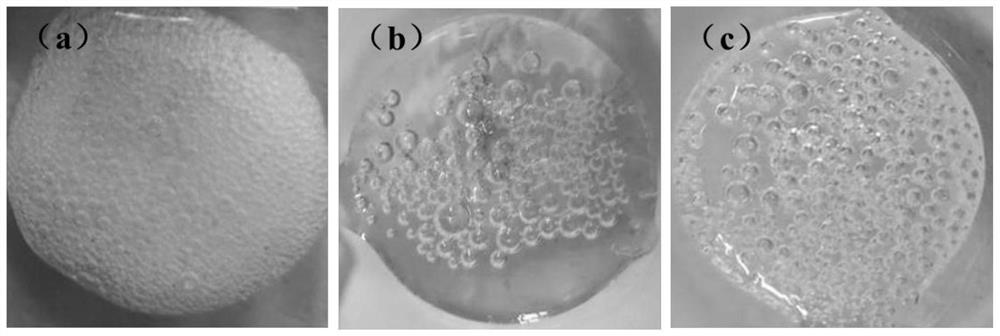

[0129] (2) a transesterification product of a polycondensation at 260 ℃, absolute pressure ≤200Pa conditions 2.7h, to give intrinsic viscosity of 0.75dL / g, φ cB Is 34.3mol%, φ cis,cB Copolyester was 63.8mol% - poly (2,2,4,4-tetramethyl-1,3-cyclobutanediol terephthalate - co-3-methyl-1,5-pentanediol ester), referred to as During the reaction, a viscous clear liquid was observed to be drawn out of the reactor, finally into a collection bottle, conduit unblocked. Melt level has remained stable during the reaction, a ...

Embodiment 2

[0130] Example 2 Synthesis

[0131] (1) a solution of N 2 The reactor atmosphere was added dimethyl terephthalate, 67.96g (0.35mol), 2,2,4,4- tetramethyl-1,3-cyclobutanediol (cis content 62%) 37.86g ( 0.2625mol), 2- methyl-1,3-propanediol 23.66g (0.2625mol) and dibutyltin oxide 0.2039g, and add the primary stabilizer and the auxiliary stabilizer 10100.068g 6260.034g, 2.5h the reaction at 220 ℃, to give the ester exchange product; during the reaction, not observed in the solid line.

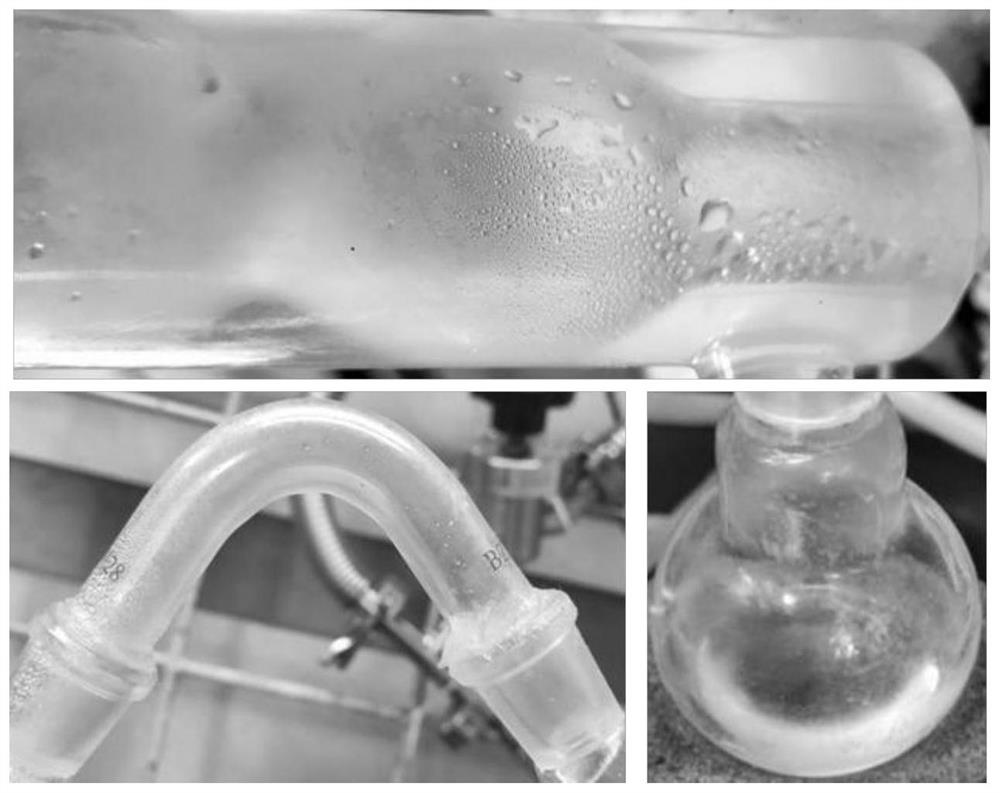

[0132] (2) a transesterification product of a polycondensation at 260 ℃, absolute pressure conditions ≤200Pa 1.5h, to give intrinsic viscosity of 0.70dL / g, φ cB Is 46.5mol%, φ cis,cB Copolyester was 64.0mol% - poly (2,2,4,4-tetramethyl-1,3-cyclobutanediol terephthalate - co-2-methyl-1,3-propylene glycol) , denoted During the reaction, a viscous clear liquid was observed to be drawn out of the reactor, finally into a collection bottle, unblocked conduit (e.g. figure 2 Indicated). Melt level has rem...

Embodiment 3

[0133] Example 3 Synthesis

[0134] (1) a solution of N 2 Reactor atmosphere of terephthalic acid was added 58.15g (0.35mol), 2,2,4,4- tetramethyl-1,3-cyclobutanediol (cis content 60%) 45.43g (0.315mol) , 1,5-pentanediol 21.87g (0.21mol) of dibutyltin oxide and 0.1744g, reacted at 210 ℃ 1h, the reaction 220 ℃ 1h, 230 ℃ reaction 5h, to obtain an esterification product. During the reaction, not observed in the solid line.

[0135] (2) esterification products of the polycondensation at 260 ℃, absolute pressure conditions ≤200Pa 3h, to give intrinsic viscosity of 0.67dL / g, φ cB Is 54.6mol%, φ cis,cB Copolyester was 62.8mol% - poly (terephthalate 2,2,4,4-tetramethyl-1,3-cyclobutanediol - 1,5-pentanediol co-ester), referred to as During the reaction, a viscous clear liquid was observed with a small amount of white solid is extracted reactor, finally into a collection bottle, conduit unblocked. Melt level has remained stable during the reaction, a small amount of bubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com