Ceramic polymer composite material and preparation method thereof, shell and preparation method thereof, and electronic equipment

A technology of polymer materials and composite materials, applied in the field of ceramic polymer composite materials and their preparation, can solve the problems of poor processing performance of ceramic polymer composite materials, and achieves improved melt fluidity, improved dispersion uniformity, and promoted bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

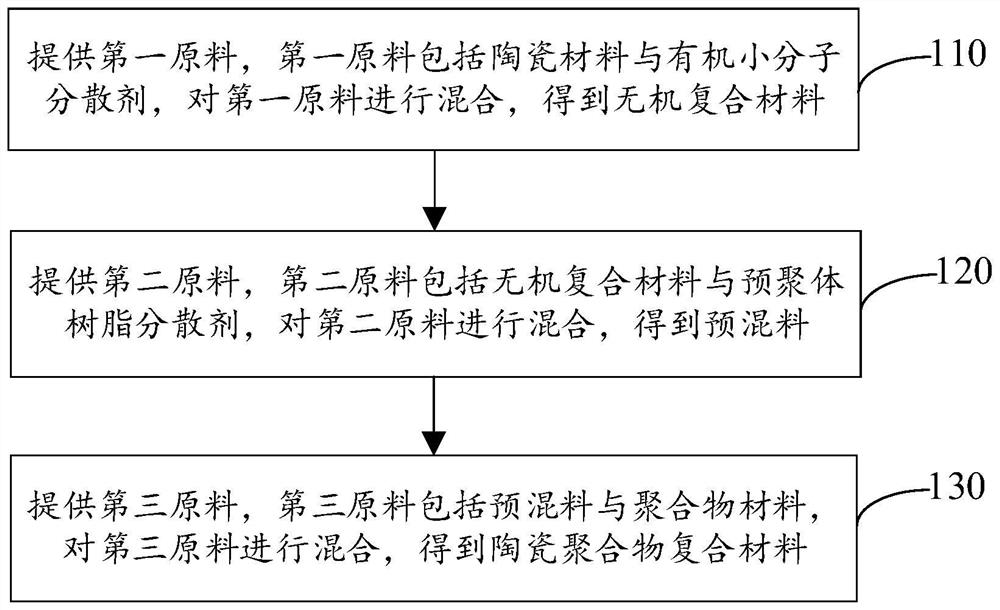

[0042] see figure 1 , figure 1 It is a flow chart of the preparation method of the ceramic polymer composite material provided in the embodiment of the present application. The ceramic polymer composite material can be the ceramic polymer composite material described in any of the above-mentioned embodiments, and the preparation method of the ceramic polymer composite material can include:

[0043] 110. Provide a first raw material, the first raw material includes a ceramic material and an organic small molecule dispersant, and mix the first raw material to obtain an inorganic composite material;

[0044] 120. Provide a second raw material, the second raw material includes an inorganic composite material and a prepolymer resin dispersant, and mix the second raw material to obtain a premix;

[0045] 130. Provide a third raw material, where the third raw material includes a premixed material and a polymer material, and mix the third raw material to obtain a ceramic-polymer com...

Embodiment 1

[0069] A ceramic polymer composite material, in parts by weight, comprising: 20 parts of polymer material, 70 parts of ceramic material, and 1.25 parts of dispersant;

[0070] The polymer material is polyphenylene sulfide, the ceramic material is zirconia with a particle size of 1 μm to 5 μm, the dispersant includes amino KH550 and epoxy resin with a molecular weight of 200 to 1500, and the mass ratio of amino KH550 to epoxy resin is 1: 2.

Embodiment 2

[0072] A ceramic polymer composite material, in parts by weight, comprising: 20 parts of polymer material, 70 parts of ceramic material, 1.25 parts of dispersant, 3 parts of pigment, 0.1 part of antioxidant, 0.15 part of lubricant, 2 parts of toughening agent share;

[0073] The polymer material is polyphenylene sulfide, the ceramic material is zirconia with a particle size of 0.5 μm to 5 μm, the dispersant includes amino KH550 and epoxy resin with a molecular weight of 200 to 1500, and the mass ratio of amino KH550 to epoxy resin is 1 : 2, the pigment is titanium dioxide, the antioxidant is pentaerythritol tetrakis (3-lauryl thiopropionate), the lubricant is pentaerythritol stearate, and the toughening agent is epoxy resin.

[0074] It can be seen that the difference between Example 2 and Example 1 is that: 3 parts of pigment, 0.1 part of antioxidant, 0.15 part of lubricant, and 2 parts of toughening agent are added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com