Spinning oil for polyester staple fibers and preparation method of spinning oil

A technology of spinning oil agent and polyester staple fiber, which is applied in the field of spinning oil agent of polyester staple fiber and its preparation, and can solve the problems of poor heat resistance and splash resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

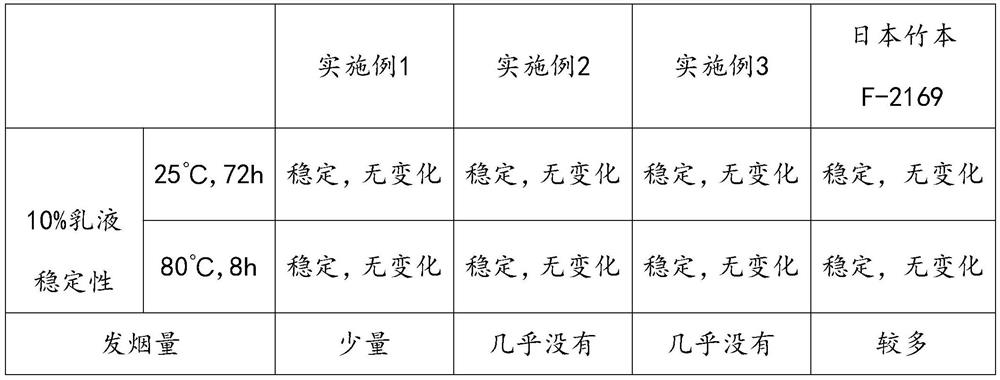

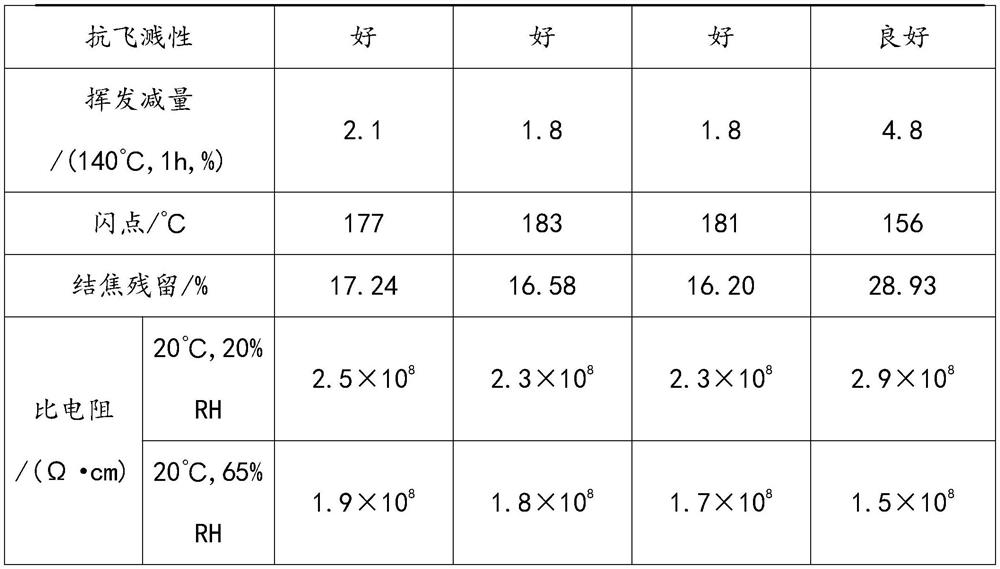

Examples

Embodiment 1

[0031] A spinning oil for polyester staple fibers, comprising the following raw materials in parts by weight: 6 parts of laurylamine polyoxyethylene ether, 6 parts of dodecyl monomethylol dimethyl ammonium chloride, isomeric tridecanol 6 parts, EL-4064 parts of castor oil polyoxyethylene ether, 1.2 parts of γ-aminopropyl triethoxysilane, 5 parts of octyl stearate, 1 part of high viscosity paraffin oil, 1 part of EVA emulsion, tripolyglycerol di 5 parts of oleic acid ester, 6 parts of SG-10 emulsifier, 2 parts of di-sec-octyl sodium maleate sulfonate, 1.2 parts of isomeric decanol polyoxyethylene ether, 0.8 parts of butyl p-hydroxybenzoate;

[0032] The preparation method of this polyester staple fiber spinning oil, comprises the following steps:

[0033] (1) Take each raw material by the above-mentioned proportioning by weight;

[0034] (2) Laurylamine polyoxyethylene ether, dedecyl monohydroxymethyl dimethyl ammonium chloride, isomeric tridecyl alcohol, castor oil polyoxyeth...

Embodiment 2

[0037] A spinning oil for polyester staple fibers, comprising the following raw materials in parts by weight: 9 parts of dodecylamine polyoxyethylene ether, 8 parts of dodecyl monomethylol dimethyl ammonium chloride, isomeric tridecanol 9 parts, 70 parts of castor oil polyoxyethylene ether, 1.4 parts of vinyl triethoxysilane, 8 parts of octyl stearate, 1.2 parts of high viscosity paraffin oil, 1.8 parts of EVA emulsion, tripolyglycerol diisostearate 5 parts, 10 parts of SG-20 emulsifier, 3 parts of dioctyl maleate sulfonate sodium, 1.5 parts of isomeric decanol polyoxyethylene ether, 1.2 parts of imidazolidinyl urea;

[0038] The preparation method of this spinning finish, comprises the following steps:

[0039] (1) Take each raw material by the above-mentioned proportioning by weight;

[0040] (2) Laurylamine polyoxyethylene ether, dedecyl monohydroxymethyl dimethyl ammonium chloride, isomeric tridecanol, castor oil polyoxyethylene ether, tripolyglycerol diisostearate, Add ...

Embodiment 3

[0043] A spinning oil for polyester staple fibers, comprising the following raw materials in parts by weight: 12 parts of dodecylamine polyoxyethylene ether, 4 parts of dedecyl monomethylol dimethyl ammonium chloride, isomeric tridecanol 12 parts, 76 parts of castor oil polyoxyethylene ether, 1.6 parts of 3-aminopropyltrimethoxysilane, 10 parts of octyl stearate, 1.2 parts of high viscosity paraffin oil, 2.8 parts of EVA emulsion, diglyceryl monooleate 5 parts, 15 parts of SG-12 emulsifier, 3 parts of dioctyl maleate sulfonate sodium, 1.8 parts of isomeric decanol polyoxyethylene ether, 1.5 parts of butyl p-hydroxybenzoate;

[0044] The preparation method of this spinning finish, comprises the following steps:

[0045] (1) Take each raw material by the above-mentioned proportioning by weight;

[0046] (2) First, 5 parts of dodecylamine polyoxyethylene ether, dedecyl monomethylol dimethyl ammonium chloride, isomeric tridecanol, castor oil polyoxyethylene ether, two polyglycero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com