A high-performance, strong-limited pure blue cspbbr 3 Quantum dots and their low-temperature preparation methods and applications

A high-performance, quantum dot technology, applied in chemical instruments and methods, semiconductor devices, luminescent materials, etc., can solve the characteristics of perovskite nanocrystals with low soft ion lattice structure, difficulty in obtaining pure blue, and fast nucleation and growth and other problems, to achieve the effects of inhibiting the growth rate of nucleation, rapidly reducing the solution temperature, and excellent spectral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

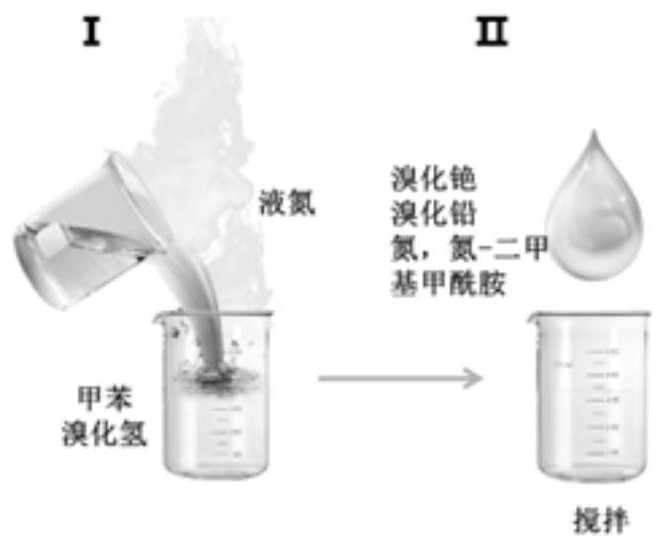

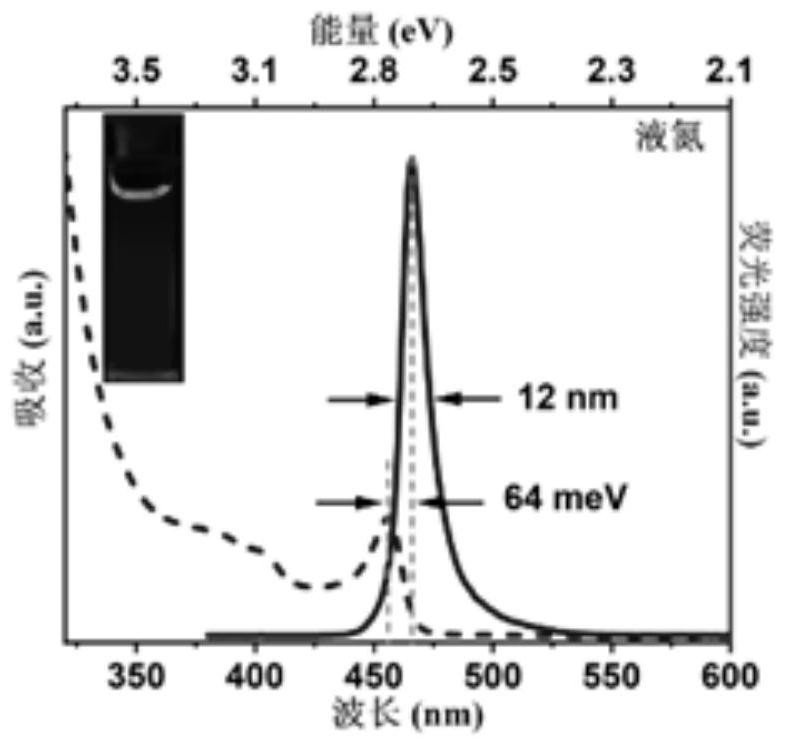

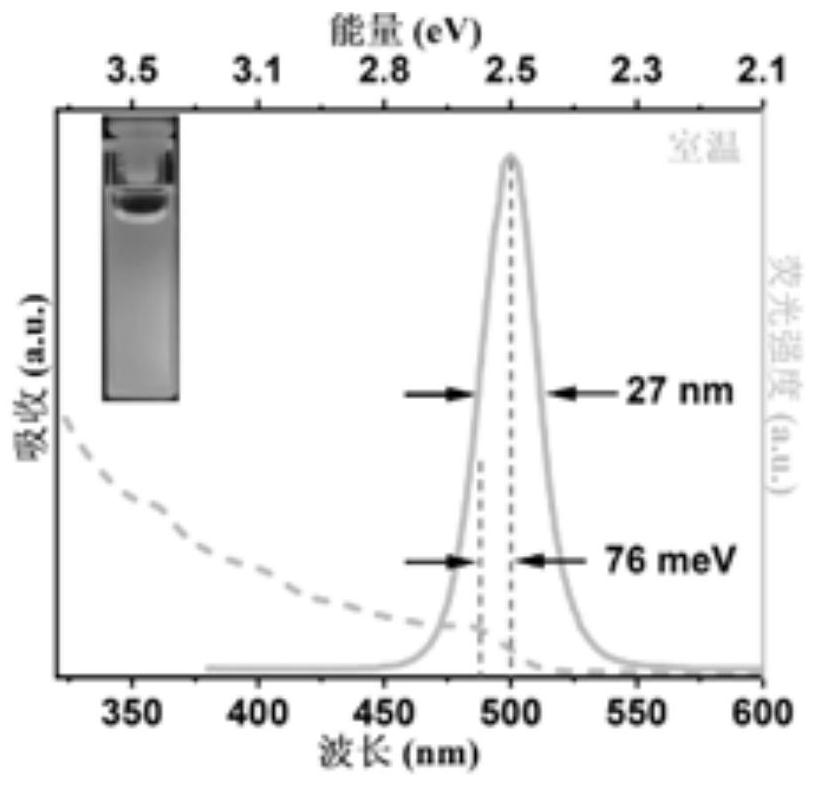

[0053] like figure 1 As shown, this embodiment provides a high-performance, strong confinement pure blue CsPbBr 3 The low-temperature preparation method of quantum dots includes the following steps:

[0054] (1) Synthesis of precursor solution

[0055] Dissolve 1 mmol of lead bromide and 1 mmol of cesium bromide in 25 mL of N,N-dimethylformamide solvent, and continuously stir for 2 h; add 2.5 mL of oleylamine and 1.25 mL of oleic acid to the mixed solution, and continue to stir for 2 h to obtain the precursor body solution;

[0056] (2) anti-solvent recrystallization

[0057] After mixing 150 μL of hydrogen bromide and 20 mL of toluene, quickly add 100 mL of liquid nitrogen to obtain a low-temperature anti-solvent solution; after 25 s, take 2 mL of the precursor solution and quickly inject it into the anti-solvent solution, the mixed solution is immediately frozen, and after a few seconds , the solid melts, and the solution is collected;

[0058] (3) Purification

[0059...

Embodiment 2

[0061] This embodiment provides a high-performance, strong confinement pure blue CsPbBr 3 The low-temperature preparation method of quantum dots includes the following steps:

[0062] (1) Synthesis of precursor solution

[0063] Dissolve 1 mmol of lead bromide and 1 mmol of cesium bromide in 20 mL of N,N-dimethylformamide solvent, and stir continuously for 3 h; add 2.5 mL of oleylamine and 1.25 mL of oleic acid to the mixed solution, and continue to stir for 3 h to obtain the precursor body solution;

[0064] (2) anti-solvent recrystallization

[0065] After mixing 100 μL of hydrogen bromide and 20 mL of toluene, quickly fill 100 mL of liquid nitrogen to obtain a low-temperature anti-solvent solution; after 25 s, take 2 mL of the precursor solution and quickly inject it into the anti-solvent solution, and the mixed solution is immediately frozen for a few seconds. After the solid melted, the solution was collected;

[0066] (3) Purification

[0067] The rotating speed of ...

Embodiment 3

[0069] This embodiment provides a high-performance, strong confinement pure blue CsPbBr 3 The low-temperature preparation method of quantum dots includes the following steps:

[0070] (1) Synthesis of precursor solution

[0071] Dissolve 2 mmol of lead bromide and 2 mmol of cesium bromide in 50 mL of N,N-dimethylformamide solvent, and continuously stir for 2 h; add 5 mL of oleylamine and 2.5 mL of oleic acid to the mixed solution, and continue to stir for 2 h to obtain the precursor solution;

[0072] (2) anti-solvent recrystallization

[0073] After mixing 300 μL of hydrogen bromide and 60 mL of toluene, quickly fill 120 mL of liquid nitrogen to obtain a low-temperature anti-solvent solution; after 25 s, take 5 mL of the precursor solution and quickly inject it into the anti-solvent solution, and the mixed solution is immediately frozen for a few seconds. After the solid melted, the solution was collected;

[0074] (3) Purification

[0075] The solution collected in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com