A kind of light porcelain silicon rubber and preparation method thereof

A silicone rubber, lightweight technology, applied in the field of silicone rubber, can solve the problems of low elongation at break, tensile strength lower than 3MPa, etc., achieve excellent mechanical properties, simple preparation method, and improve the effect of porcelain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

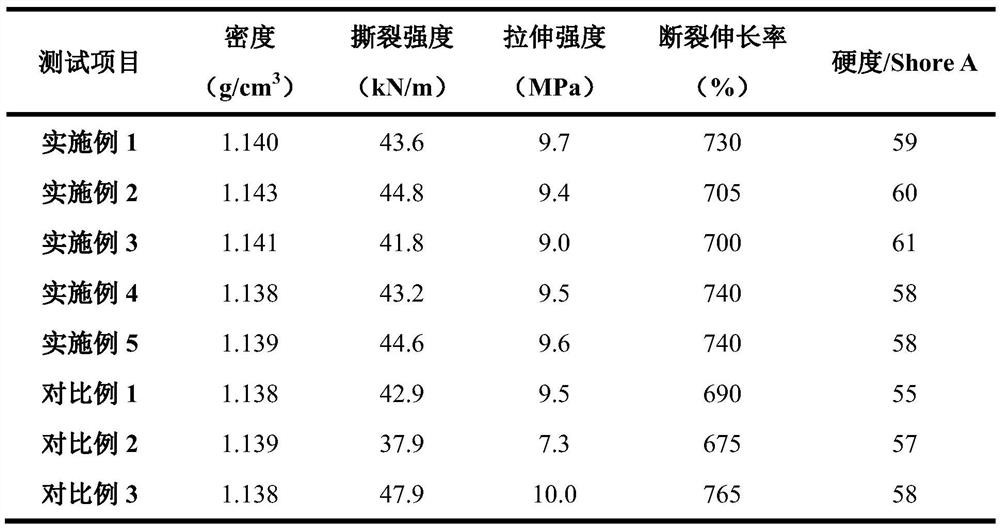

Embodiment 1

[0043] A light-weight porcelainizable silicone rubber, the preparation method of which comprises the following steps:

[0044] 1) 93 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.05 mol% (number-average molecular weight 620,000 g / mol) and 7 parts by mass of methyl vinyl silicone rubber with a vinyl content of 3.0 mol % (number-average molecular weight of 640,000 g / mol) mol), 40 parts by mass specific surface area 280m 2 / g of fumed silica, 6 parts by mass of hydroxy silicone oil with a hydroxyl content of 8.5 wt %, 0.6 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 1.2 wt %, and 2 mass parts of γ-piperazinyl propyl methyl dimethyl dimethyl Oxysilane was added to the kneader, mixed for 2 hours, then heated to 150 °C and mixed for 3 hours, then vacuum-mixed at 120 °C for 1 hour, and cooled to room temperature to obtain a silicone rubber base rubber;

[0045] 2) Combine the silicone rubber base rubber of step 1), 0.4 parts ...

Embodiment 2

[0048] A light-weight porcelainizable silicone rubber, the preparation method of which comprises the following steps:

[0049]1) 98 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.03 mol % (number average molecular weight 700,000 g / mol) and 2 mass parts of methyl vinyl silicone rubber with a vinyl content of 4.0 mol % (number average molecular weight of 500,000 g / mol) mol), 50 parts by mass specific surface area 200m 2 / g of fumed silica, 9 parts by mass of hydroxy silicone oil with a hydroxyl content of 5.0 wt %, 0.5 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 1.5 wt %, and 1.5 parts by mass of N-phenyl-3-aminopropyl trimethylene Oxysilane was added to the kneader, mixed for 2 hours, then heated to 160°C and mixed for 2 hours, then vacuum-mixed at 130°C for 0.5 hours, and cooled to room temperature to obtain a silicone rubber base rubber;

[0050] 2) The silicone rubber base rubber of step 1), 0.3 parts by mass of boro...

Embodiment 3

[0053] A light-weight porcelainizable silicone rubber, the preparation method of which comprises the following steps:

[0054] 1) 95 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.08 mol% (number-average molecular weight 500,000 g / mol) and 5 parts by mass of methyl vinyl silicone rubber with a vinyl content of 2.0 mol % (number-average molecular weight of 700,000 g / mol) mol), 30 parts by mass specific surface area 300m 2 / g fumed silica, 5 parts by mass of hydroxy silicone oil with a hydroxyl content of 10.0 wt %, 0.9 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 1.0 wt %, and 3 parts by mass of γ-aminopropyltriethoxysilane Kneader, kneading for 1 hour, then heated to 140°C and mixed for 4h, then vacuum-mixed at 120°C for 1.5h, cooled to room temperature to obtain silicone rubber base rubber;

[0055] 2) The silicone rubber base rubber of step 1), 0.8 parts by mass of boron oxide with an average particle size of 100 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com